-

E-mail

hzhuf@163.com

-

Phone

13503187732

-

Address

Hongwuzhuang Village, Zaoqiang County, Hebei Province

Zaoqiang Runhe Environmental Protection Equipment Co., Ltd

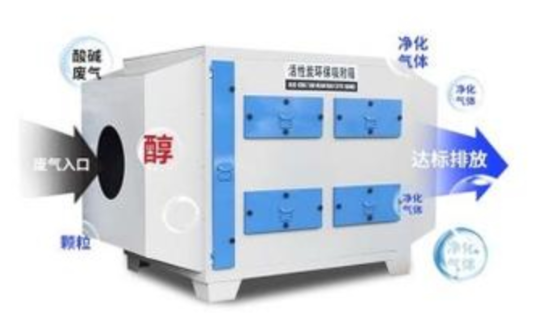

Basic structure of activated carbon adsorption device

Main structure:

Box body: Material options include carbon steel, stainless steel (304/316L, suitable for high temperature>80 ℃ or corrosive environments), or fiberglass, with sealing and corrosion resistance required

Activated carbon layer: filled with granular (diameter 3-5mm) or honeycomb shaped activated carbon, arranged in layers (2-4 layers), with a thickness of 300-500mm per layer

Supporting structure: stainless steel wire mesh or perforated plate is used to prevent the loss of activated carbon and ensure uniform distribution of airflow

Air intake/exhaust system: The air intake is usually located at the bottom or side, and the air outlet is located at the top or the other side, equipped with an airflow distribution device

Working principle and process of activated carbon adsorption device:

By utilizing the specific surface area (500-1500m ²/g) and microporous structure of activated carbon, pollutants (such as VOCs and odor molecules) in exhaust gas can be physically and chemically adsorbed.

The exhaust gas is introduced by the fan → uniformly passes through the activated carbon layer → pollutants are adsorbed → purified gas is discharged

When activated carbon is saturated (pressure difference ≥ 2 times the initial value or outlet concentration exceeds the standard), it needs to be replaced or regenerated.

Main types and characteristics of activated carbon adsorption devices and accessories:

Activated carbon adsorption device and accessories:

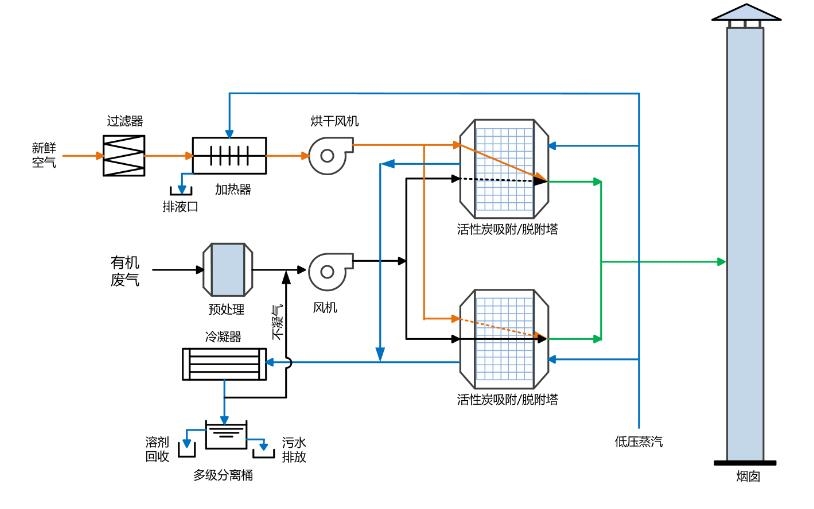

1. Power and transmission system

Fan: power source, responsible for introducing and discharging purified gas from exhaust gas, selected according to air volume and pressure, and designed for anti-corrosion/explosion-proof conditions

Pipeline system: connecting equipment and pollution sources, made of corrosion-resistant material (stainless steel/PVC)

Valves: Control the direction and flow of airflow, including manual/pneumatic/electric valves, used for system start stop, switching, and regulation

2. Preprocessing and post-processing attachments

Pre filter: installed in front of the air inlet to handle dust and particulate matter (≤ 1mg/m ³) and prevent blockage of activated carbon pores

Condensation device: Reduce the temperature of high-temperature exhaust gas (≤ 40 ℃) and protect the performance of activated carbon

Post filter: installed at the air outlet to prevent activated carbon dust from being discharged with the purified gas

3. Monitoring and Control System

Differential pressure gauge: monitors the resistance of the activated carbon layer and determines the saturation state

Temperature sensor: multi-point monitoring

Concentration sensor: Real time monitoring of inlet and outlet exhaust gas concentration, controlling equipment start stop or switching

Control system: achieve automatic operation