-

E-mail

hzhuf@163.com

-

Phone

13503187732

-

Address

Hongwuzhuang Village, Zaoqiang County, Hebei Province

Zaoqiang Runhe Environmental Protection Equipment Co., Ltd

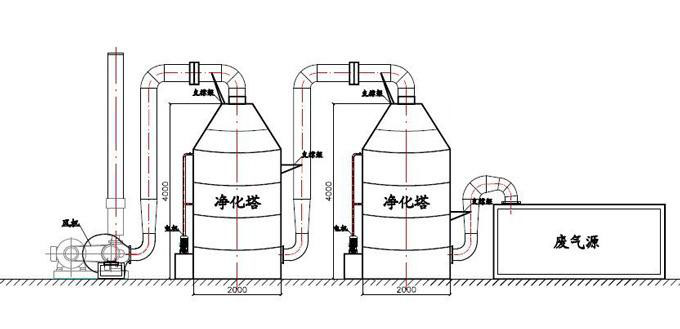

The spray tower+defogging tower for electrophoretic drying waste gas treatment is a combination process of "spray absorption tower+defogging purification tower" to treat organic volatile compounds (VOCs), paint mist, and a small amount of acidic pollutants in the waste gas, meeting emission requirements.

Spray tower (absorption tower): After the exhaust gas enters the tower, it comes into full contact with the atomized absorption liquid of the spray system. Through physical dissolution and chemical adsorption, the paint mist particles, soluble VOCs, and a small amount of acidic substances in the exhaust gas are treated.

Defogging tower (defogger): Its function is to "dehydrate and defog". The exhaust gas treated by the spray tower contains water mist and fine particles. After entering the demister, the liquid water mist in the exhaust gas is separated to avoid the phenomenon of "white smoke" at the subsequent discharge outlet and reduce the impact on subsequent equipment (such as activated carbon boxes).

Process flow of electrophoretic drying waste gas treatment:

Electrophoretic drying exhaust gas → pretreatment (optional, such as filtering paint mist) → spray tower (washing absorption) → dehazing tower (dehydration dehazing) → standard emission.

Design and selection of spray tower and defogging tower:

1. Key points of spray tower design

Material selection: FRP (fiberglass reinforced plastic) is selected, which is acid and alkali resistant, corrosion-resistant, and suitable for the slightly corrosive environment of electrophoretic waste gas;

Spray system: Adopting a multi-layer spray design (usually 2-3 layers), the nozzle uses a spiral atomizing nozzle to ensure uniform atomization of the absorbing liquid and improve gas-liquid contact efficiency.

Circulating system: equipped with a circulating water tank and a spray pump, the absorbent can be recycled and regularly replenished and replaced to reduce operating costs; The water tank needs to be equipped with a drainage outlet to facilitate the cleaning of settled paint residue.

2. Design points of defogging tower

Mist remover type: For small and medium-sized equipment, a wire mesh mist remover (with high separation efficiency and low resistance) is selected; When there is a large amount of exhaust gas or water mist, use a baffle defogger.

Material matching: The defogger material is made of PP or FRP, which is consistent with the material of the spray tower to avoid corrosion damage.

Drainage design: An inclined guide plate and a collection tank should be installed at the bottom of the demister tower to promptly discharge the separated wastewater and prevent the accumulation of liquid from flowing back to the spray tower or discharge outlet.

Spray tower, defogging tower, electrophoresis drying waste gas treatment, operation and maintenance:

Spray liquid management: Regularly check the pH value and concentration of the spray liquid, and replenish the absorbent in a timely manner.

Cleaning of defogger: Regularly (1-2 times a month) check whether the defogger is scaled or blocked. It can be treated by reverse flushing or chemical cleaning (such as using weak alkaline solution) to ensure defogging efficiency.

Equipment anti-corrosion: Regularly inspect the anti-corrosion coating of the spray tower body, pipelines, and flange connections, and promptly repair any damages found. Pay special attention to the connecting pipelines between the spray tower and the demister tower to avoid exhaust gas leakage.

Air volume matching: The air volume processed by the equipment needs to be matched with the emission of electrophoresis drying waste gas to avoid insufficient gas-liquid contact caused by high air volume or insufficient negative pressure inside the equipment caused by low air volume.