-

E-mail

1554014736@qq.com

-

Phone

18915252038

-

Address

No. 886, Xishan District, Wuxi

Product Categories

Wuxi Koni Heavy Industry Machinery Co., Ltd

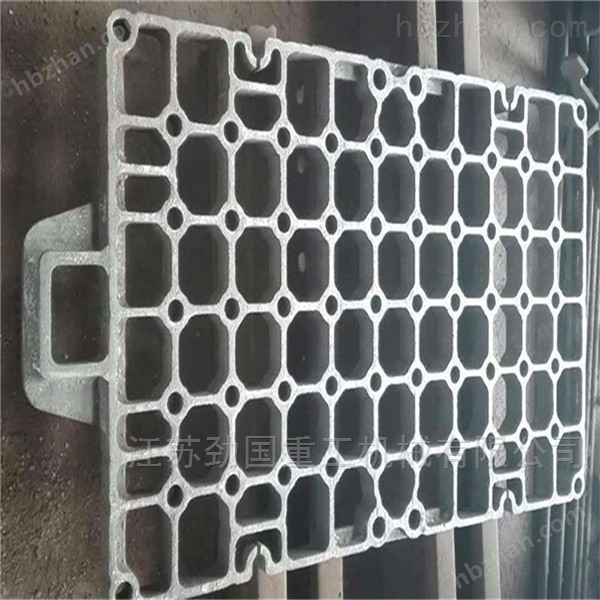

1Cr25Ni20Si2 material rack wear-resistant cast steel

NegotiableUpdate on 01/10

- Model

- Nature of the Manufacturer

- Producers

- Product Category

- Place of Origin

Overview

Casting performance: Steel has a high melting point (above 1500 ℃), poor flowability, large shrinkage rate (about 2%), and is prone to defects such as shrinkage and cracks, which need to be controlled through process optimization (such as riser design and heat treatment). $r $n $r $n Heat Treatment: Steel castings typically require normalizing, annealing, or quenching+tempering to refine grain size, eliminate internal stress, and improve mechanical properties. Weldability of $r $n $r $n: Most cast steels can be welded, but preheating and post weld heat treatment are required to avoid cracks. Typical application areas: Heavy machinery such as rolling mill frames, mining equipment gears, crane turntables, etc. $r $n $r $n Energy equipment: water and electricity valves, wind turbine hubs, nuclear power components. $r $n $r $n Transportation

Product Details