-

E-mail

liuyanhe@zhderx.com

-

Phone

13005602816

-

Address

Zhuhai New Olin Technology Park

- Acetone wastewater low-temperature evaporation treatment equipment

- Sodium sulfate mixed salt solution dryer

- Polyethylene glycol wastewater concentration equipment

- Dimethyl sulfoxide wastewater treatment equipment

- Organic solvent wastewater concentration treatment equipment

- Wastewater phosphoric acid recovery equipment

- Mother liquor drying machine

- Electroplating wastewater evaporation crystallization equipment

Zhuhai Derunxin General Machinery Co., Ltd

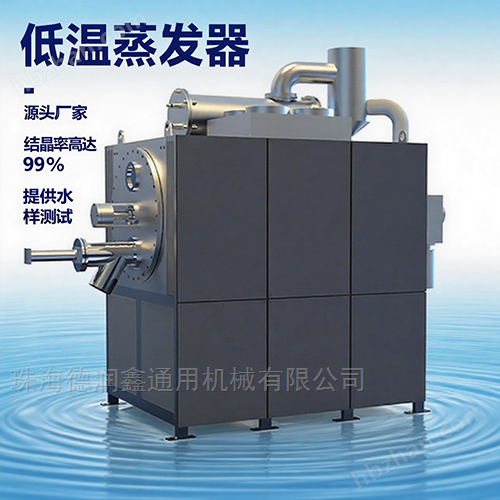

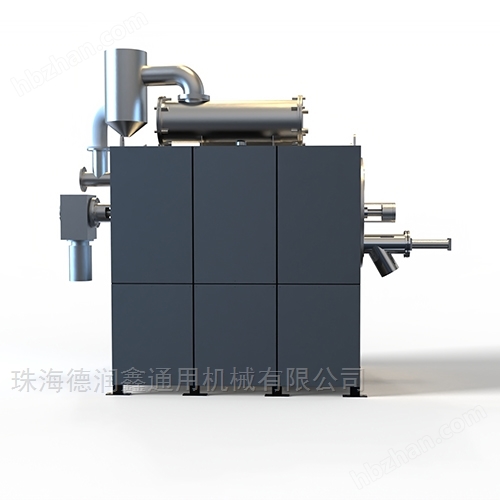

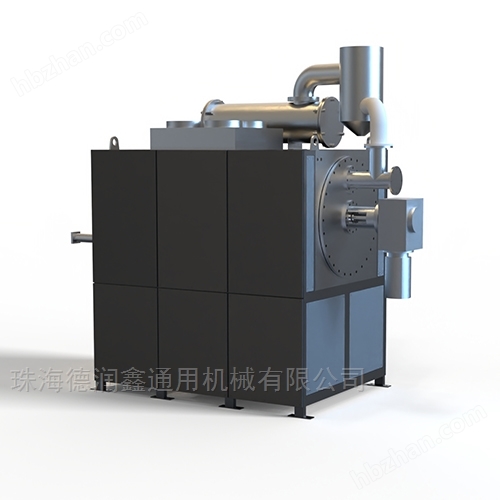

Acetone wastewater low-temperature evaporation treatment equipment

- Model

- Nature of the Manufacturer

- Producers

- Product Category

- Place of Origin

working principle

Acetone wastewater low-temperature evaporation treatment equipmentFirstly, pretreatment of acetone wastewater is carried out to remove suspended impurities through explosion-proof filtration, and the pH is adjusted to neutral to avoid equipment corrosion. The pre treated wastewater enters the low-temperature evaporation chamber and lowers its boiling point in a vacuum environment (vacuum degree -0.08~-0.09MPa). Combined with a low-temperature heat source at 40-60 ℃, acetone and water are azeotropically evaporated (acetone boiling point 56.5 ℃, lower than water). The steam generated by evaporation enters the condensation system and is first condensed to recover high-purity acetone through staged condensation technology (utilizing the difference in condensation temperature between acetone and water). The remaining steam is condensed into low concentration organic wastewater, which enters the advanced treatment unit (such as activated carbon adsorption+biochemical treatment) and ultimately meets the standard for discharge or reuse. The recovered acetone can be reused in production after simple purification.

Features of the equipment

Efficient recycling with significant economic benefits: The recovery rate of acetone can reach over 90%, with a purity of ≥ 95%. Direct reuse in production can reduce raw material procurement. Calculated based on the daily treatment of 10 tons of acetone wastewater with a concentration of 10%, approximately 300 tons of acetone can be recovered annually, saving costs of over 2 million yuan.

Low temperature explosion-proof, safe and reliable: using 40-60 ℃ low-temperature evaporation, combined with explosion-proof motor, static elimination device and gas detection alarm system, to avoid the risk of combustion caused by acetone volatilization from the source, in compliance with explosion-proof safety standards (Ex d Ⅱ BT4).

Energy saving and low consumption:Acetone wastewater low-temperature evaporation treatment equipmentCompared to traditional distillation equipment, which saves more than 60% energy, heat pump technology achieves thermal energy recycling, and the energy consumption for treating 1 ton of acetone wastewater is only 8-12 kW · h, with low operating costs.

Fully automated control: The PLC system monitors temperature, pressure, liquid level, and acetone concentration in real time, automatically adjusts the feeding amount and heating power, achieves unmanned operation, and reduces operational risks.

Anti corrosion design: The parts in contact with wastewater are made of 316L stainless steel and PTFE coating, which is resistant to acetone corrosion and has a service life of ≥ 8 years.

Strong adaptability: capable of treating wastewater with acetone concentration of 5% -30%, compatible with small amounts of azeotropic solvents such as methanol and ethanol, with a single equipment processing capacity of 5-200m ³/d, meeting the needs of enterprises of different scales.

Classic Case

A certain pharmaceutical company's acetone wastewater treatment project: The company generates 30m ³ of acetone wastewater per day (acetone concentration 12%, COD 35000mg/L). After using this set of equipment, the acetone recovery rate is 92%, and about 3.4 tons of acetone with a purity of 96% are recovered per day, saving about 2.6 million yuan in raw material costs annually; After treatment, the COD of the wastewater was reduced to 85mg/L, and all of it was reused for workshop cleaning, saving an annual water cost of 150000 yuan. It passed the dual acceptance of explosion prevention and discharge by the environmental protection department.

A mixed organic wastewater treatment project at a certain paint factory: targeting the mixed wastewater (COD 28000mg/L) containing acetone (8%) and butyl ester (3%) in the factory, the equipment optimizes the condensation parameters to achieve priority recovery of acetone, with a recovery rate of 90%. The treated wastewater is discharged after biochemical treatment to meet the standard, reducing the annual disposal of hazardous waste by more than 1000 tons and achieving a comprehensive economic benefit of over 1.2 million yuan.