The counter current aluminum core of the air heat exchanger is made of high-purity 1060 aluminum, combined with a counter current structural design, which combines lightweight and high heat transfer efficiency. It can efficiently recover air waste heat and can adapt to multiple scenarios after anti-corrosion coating treatment. Supporting modular customization and easy installation and maintenance, it is the core component for energy-saving upgrades of air heat exchangers.

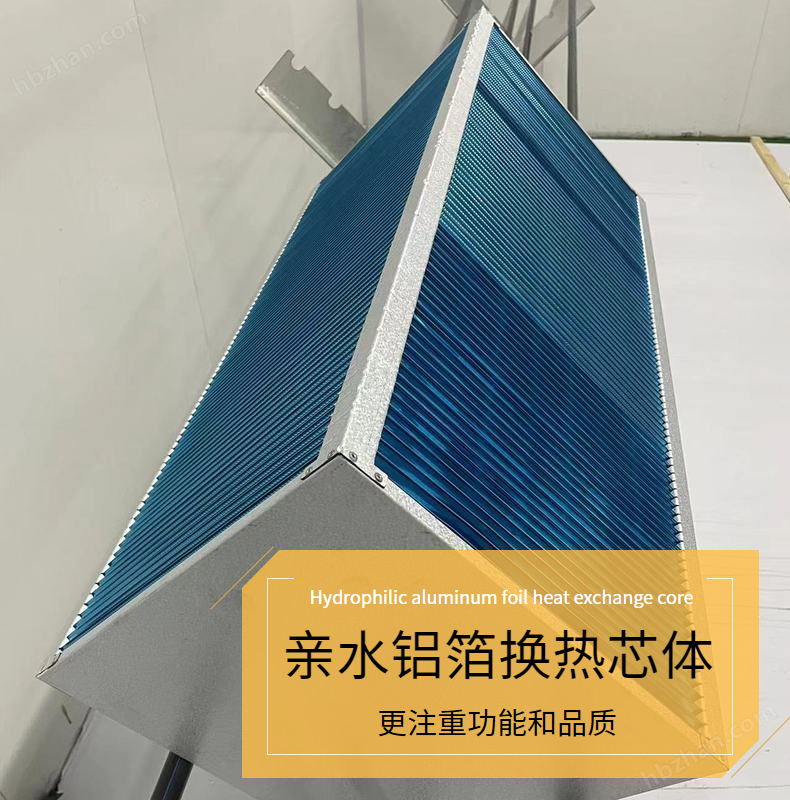

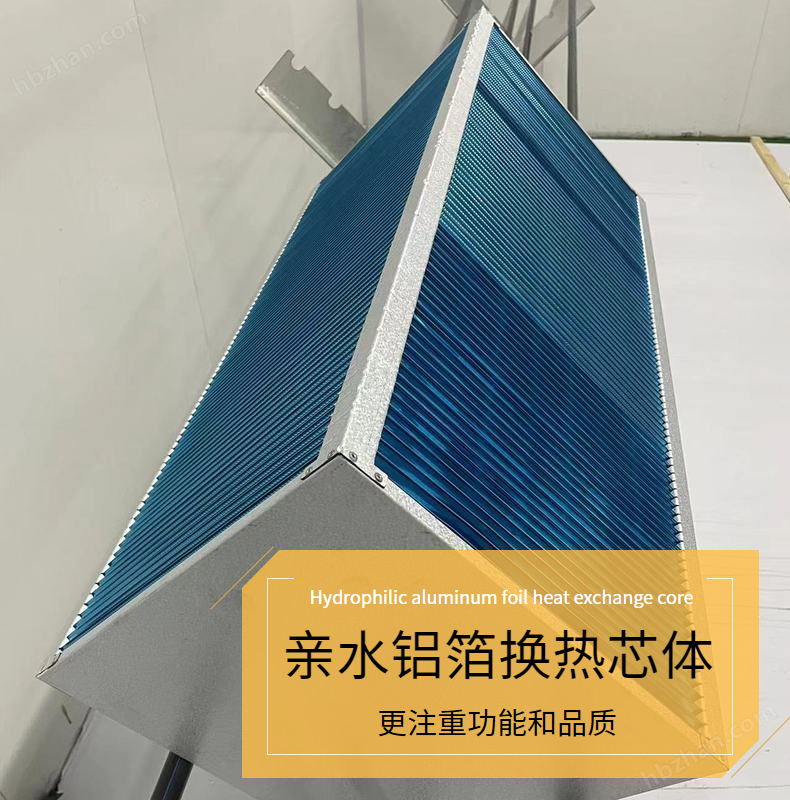

Air heat exchanger counterflow aluminum coreIt is the core component of air heat exchangers to achieve efficient heat recovery and transfer. The combination of its material characteristics and counterflow structure design is suitable for the dual requirements of lightweight, high thermal conductivity, and heat transfer efficiency in air heat exchange scenarios. The core is made of high-purity 1060 aluminum material, which has a thermal conductivity coefficient of up to 237W/(m · K), far superior to ordinary alloy materials. It can quickly achieve heat transfer between cold and hot air, reducing heat loss during the conduction process; At the same time, 1060 aluminum has good ductility and formability, and can be made into complex flow channel structures through precision rolling and stamping processes. The material density is only 2.7g/cm ³, which reduces the weight of the air heat exchanger by more than 40% compared to stainless steel cores. It is particularly suitable for installation scenarios that are sensitive to equipment weight, such as suspended ceilings and wall mounted installations.

From the perspective of heat exchange structure, the counter current design is the core advantage of this core. Unlike co current or cross current structures, in counter current structures, cold and hot air flows in opposite directions within the core. This flow pattern allows the cold and hot fluids to maintain a large temperature difference throughout the entire heat exchange process, utilizing the driving force of heat transfer. By optimizing the flow channel layout through fluid dynamics simulation, the contact path between cold and hot air inside the core is longer and more complete. Through actual testing, it has been found that under the same air volume and temperature difference conditions, the heat transfer efficiency of the counter current aluminum core is 25% -30% higher than that of the co current core, and the air waste heat recovery rate can reach over 70%. In addition, the flow channel cross-section of the core adopts a gradient design, with a wider inlet flow channel to reduce the resistance of air entering, and a narrower outlet flow channel to enhance air turbulence and further strengthen heat transfer efficiency. At the same time, it effectively avoids local overheating or uneven heat transfer caused by air retention in the flow channel.

In terms of weather resistance and practicality, the aluminum core has undergone a special surface treatment process to enhance its performance. A layer of high-temperature and anti-corrosion coating with a thickness of about 8 μ m is sprayed on the surface of the core. This coating has excellent resistance to moisture, heat, and salt spray, and can resist the erosion of water vapor, dust, and corrosive gases in the air, avoiding oxidation and corrosion of aluminum materials exposed to humid environments for a long time. According to third-party testing, after continuous testing for 1000 hours in a humid and hot environment with a temperature of 40 ℃ and a relative humidity of 95%, there were no obvious oxidation marks on the surface of the core, and the heat transfer efficiency only decreased by less than 2%. This meets the needs of long-term operating scenarios such as civil buildings, industrial plants, and rail transit. At the same time, the structural strength of the aluminum core has been optimized by adding channel support ribs and edge reinforcement design, which improves the core's resistance to deformation while ensuring lightweight. It can withstand air pressure fluctuations of 0-500Pa, avoiding deformation or damage to the core due to changes in wind pressure.

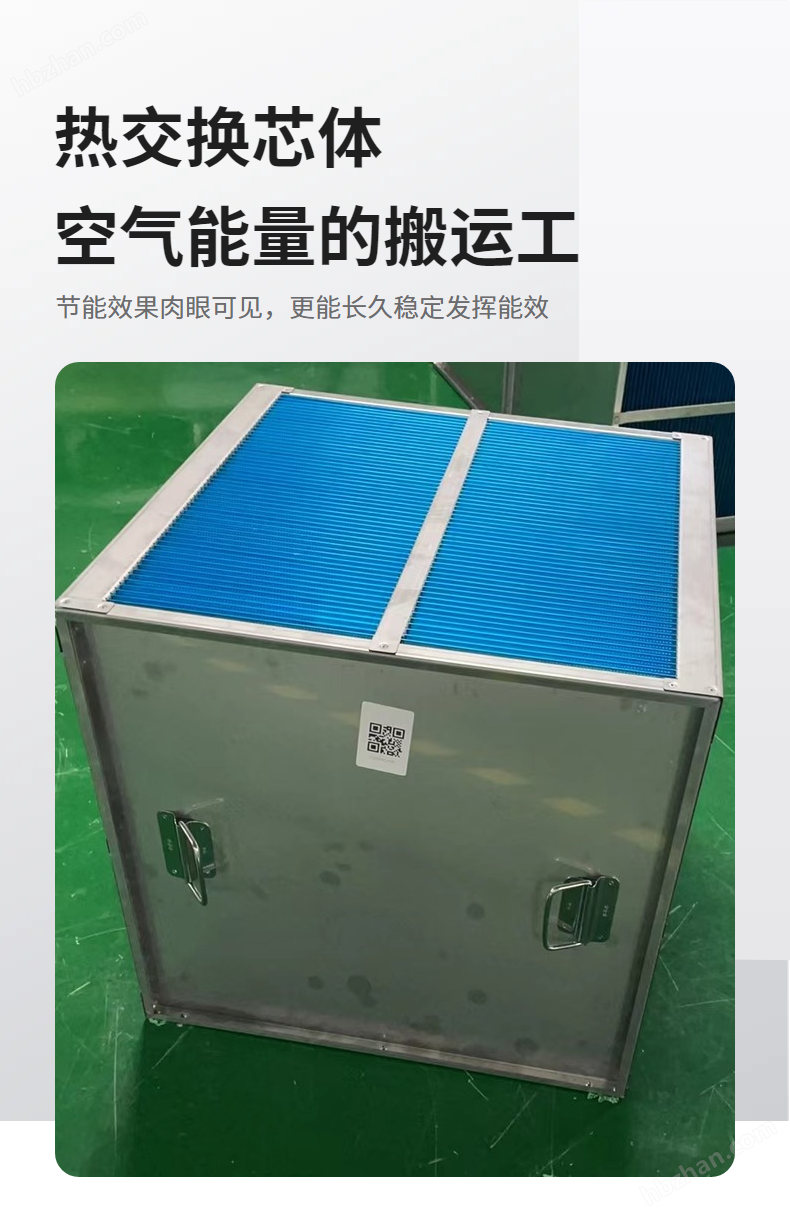

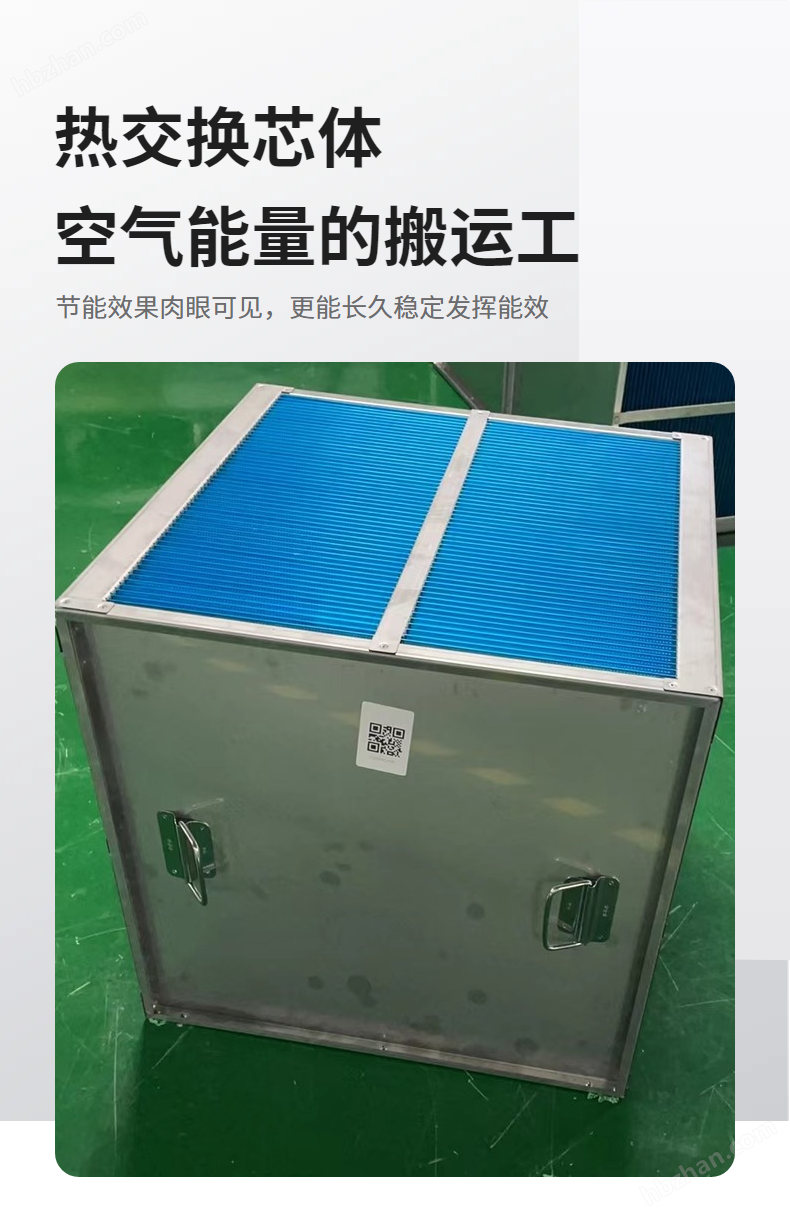

Adaptability and ease of installation and maintenance are also important features of this core. It adopts a standardized module design, which can flexibly combine the number and size of core units according to the air volume (range 500-10000m ³/h) and heat exchange area requirements of the air heat exchanger, and adapt to different scenarios such as household fresh air systems, commercial central air conditioning fresh air heat exchange modules, and industrial plant waste heat recovery equipment. During installation, the core body is connected to the heat exchanger shell through a snap or flange connection method, without the need for complex welding processes. A single person can complete the installation with simple tools, greatly reducing the construction period. In daily maintenance, due to the smooth surface of aluminum and the anti sticking properties of the coating, dust and impurities are not easy to adhere. They can be quickly cleaned by compressed air blowing or low-pressure water gun flushing. The maintenance frequency is only one-third of that of traditional paper or fiber cores, significantly reducing the cost of later operation and maintenance.

In practical application scenarios, the energy-saving value and practicality of the core have been fully verified. In the residential fresh air system, equipped with this counter current aluminum core heat exchanger, more than 70% of the heat in the exhaust can be recovered. In winter, it can preheat the outdoor cold air to near indoor temperature, and in summer, it can pre cool the outdoor hot air, reducing the load on the air conditioning or heating system by 30% -40% and saving 20% -25% of electricity bills per month; In industrial plants, it is used to recover the high-temperature air waste heat generated during the production process, preheat the workshop fresh air, reduce natural gas consumption by 12000 to 15000 cubic meters per year, and reduce carbon emissions by about 20 tons. In addition, in the field of rail transit, this core is compatible with the fresh air heat exchange system of subway and high-speed rail carriages. Its lightweight design meets the needs of vehicle weight reduction, and its efficient heat exchange performance ensures stable temperature inside the carriage, improving passenger comfort.

Air heat exchanger counterflow aluminum coreWith the high thermal conductivity and lightweight advantages of aluminum material, the efficient heat transfer characteristics of counterflow structure, as well as excellent weather resistance and convenient maintenance performance, it has become a key component in the field of air heat exchange to improve energy utilization and reduce energy consumption. Against the backdrop of continuous promotion of green building and industrial energy-saving policies, this core provides efficient and reliable heat exchange solutions for air heat exchange equipment in different scenarios, helping to achieve the dual goals of energy conservation, consumption reduction, and comfortable experience.