-

E-mail

409070541@qq.com

-

Phone

18065929385

-

Address

No. 38-3 Xinhua Road, Siming District, Xiamen City

Xiamen Dace Environmental Protection Equipment Co., Ltd

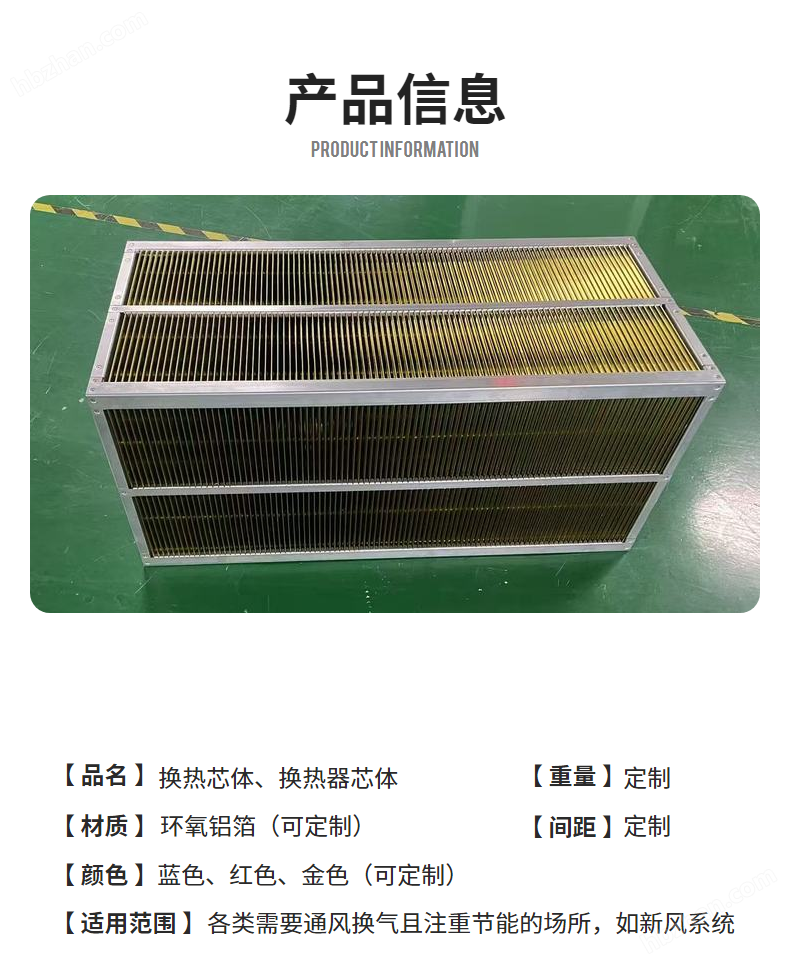

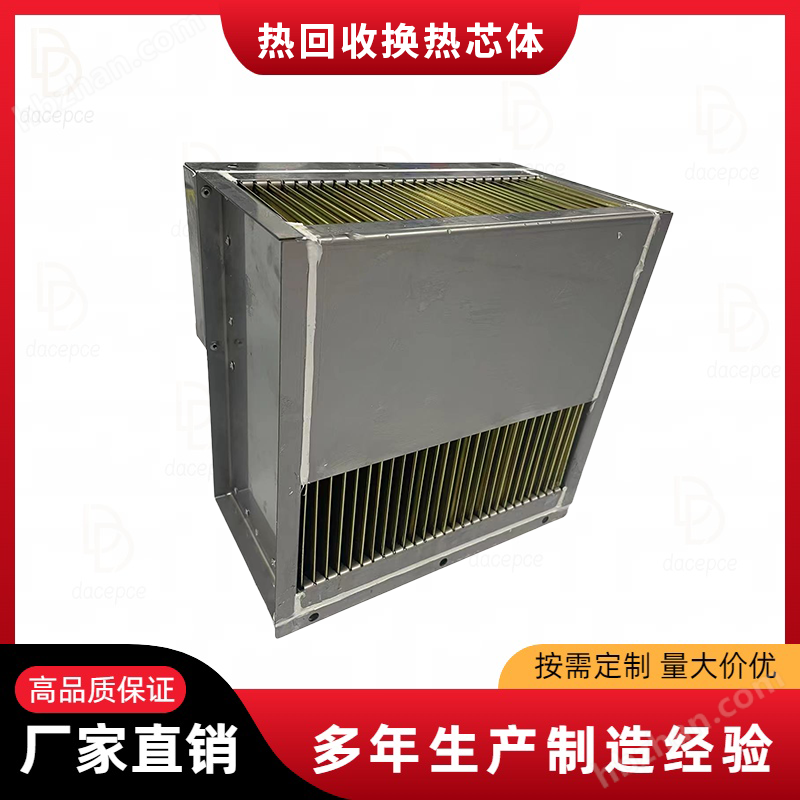

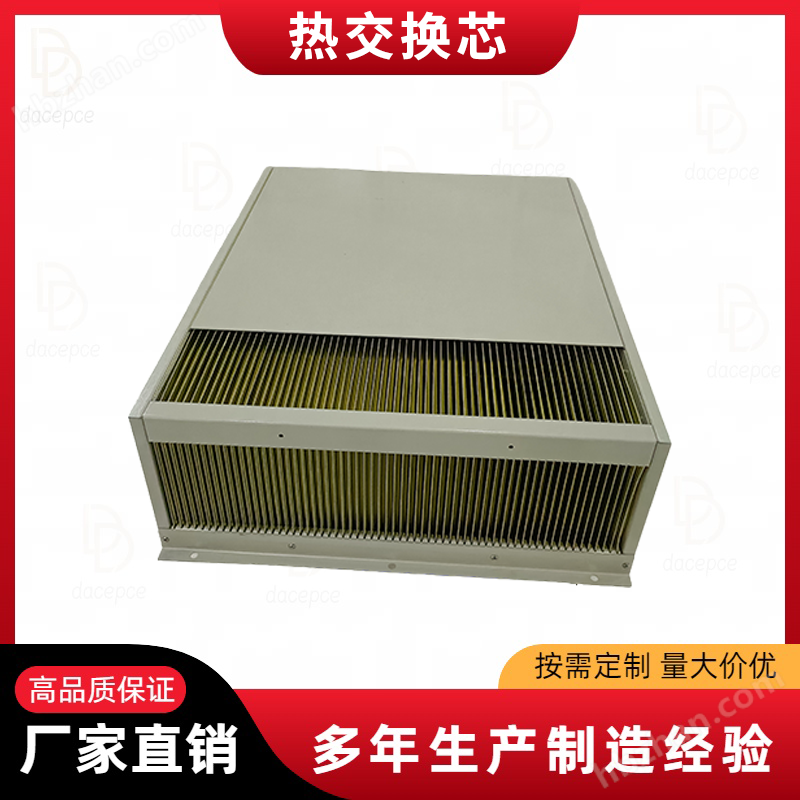

Aluminum foil heat exchange core of wind air heat exchanger

- Model

- Nature of the Manufacturer

- Producers

- Product Category

- Place of Origin

Aluminum foil heat exchange core of wind air heat exchangerIt is the core functional carrier of wind air heat exchangers, specifically developed for gas heat exchange needs in fields such as building fresh air, industrial ventilation, and central air conditioning. With efficient heat exchange performance and stable operation, it has become a key component in ventilation and heat exchange systems.

The product uses high-quality imported hydrophilic aluminum foil as the core material. After special anti-corrosion and anti-oxidation treatment, the aluminum foil not only has a thermal conductivity of up to 237W/(m ・ K), which can quickly realize the energy transfer between indoor and outdoor air, but also has good moisture resistance and anti-aging characteristics, that is, it can be used stably for a long time in a high humidity and ventilated environment, and its service life is more than 50% longer than that of ordinary aluminum foil core.

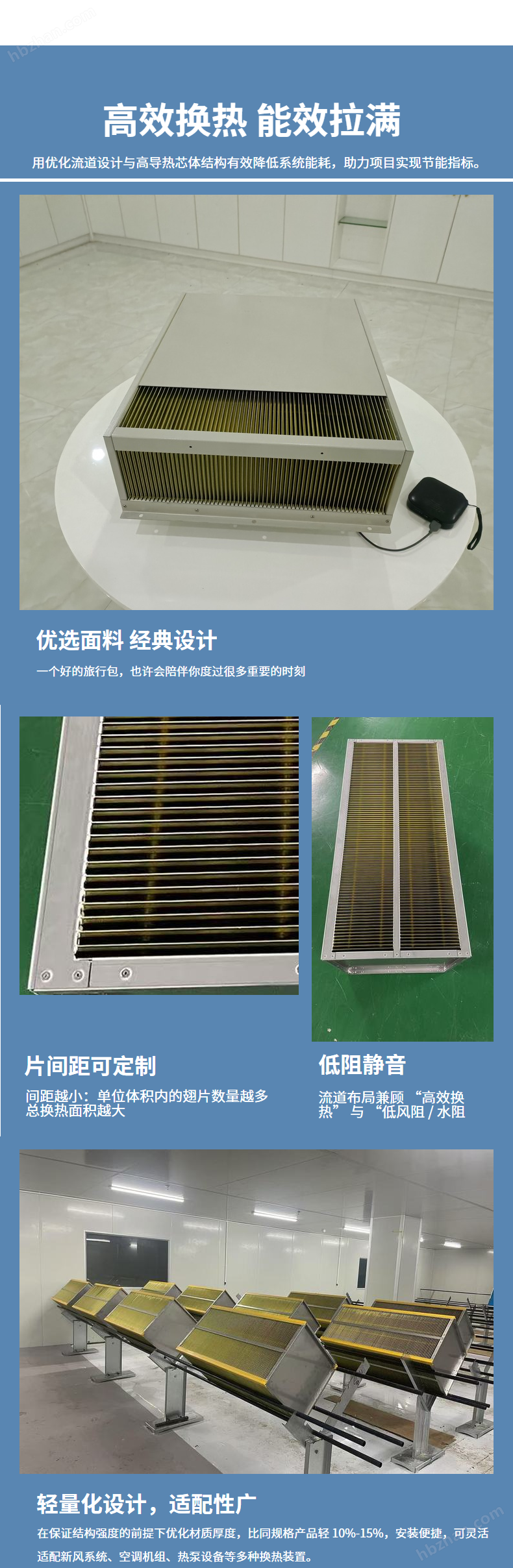

In terms of structural design,Aluminum foil heat exchange core of wind air heat exchangerAdopting a cross countercurrent flow channel layout, a corrugated flow channel structure is formed by precision mold stamping, allowing indoor exhaust air and outdoor fresh air to fully contact inside the core. The heat transfer area is increased by 60% compared to traditional flat core, and the heat transfer efficiency is improved to over 85%.

The optimized design of the flow channel effectively reduces air flow resistance, with an air flow resistance of ≤ 80Pa, which will not have a significant impact on the air volume of the ventilation system, ensuring indoor ventilation effectiveness while reducing fan energy consumption.

The assembly process of the core adopts high-frequency ultrasonic welding technology, and the welding points are firm and tight, without the risk of loosening or falling off, ensuring that the core maintains structural stability under long-term airflow impact and avoiding problems such as air leakage and cross flow.

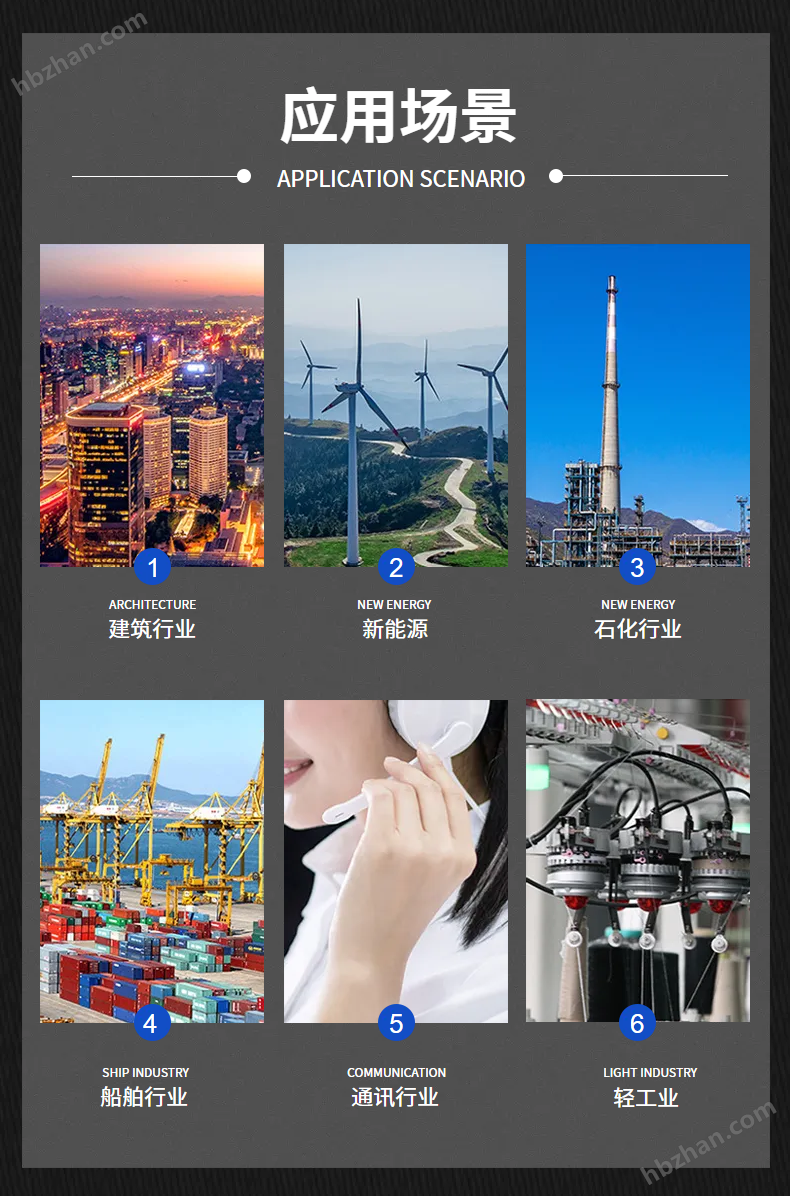

This product has a wide range of application scenarios and can be adapted to the fresh air systems of large public buildings such as shopping malls, office buildings, hospitals, and schools. It is also suitable for ventilation equipment in industrial workshops and central fresh air systems in households.

In public buildings, it is possible to preheat outdoor cold air in winter and cool outdoor hot air in summer, reducing the cooling and heating load of the air conditioning system. On average, this can reduce air conditioning energy consumption by 25% to 35%, effectively saving electricity resources; In industrial workshops, it is possible to recover heat or cold from workshop exhaust, regulate indoor temperature, improve working environment, and reduce production energy consumption.

The product supports customized production and can adjust the size, thickness, channel density and other parameters of the core according to the air volume and pressure requirements of the ventilation equipment, meeting the personalized needs of different scenarios. It also has the advantages of light weight and small volume, making it easy to install and transport without increasing the installation difficulty and space occupation of the ventilation equipment.

The hydrophilic coating on the surface of the core not only improves heat transfer efficiency, but also has a self-cleaning effect, reducing the adhesion of dust and particles, and lowering maintenance frequency. The product has passed the testing of the National Air Conditioning Equipment Quality Supervision and Inspection Center, and all performance indicators meet the GB/T 21087-2007 "Air Air Energy Recovery Device" standard, ensuring reliable and guaranteed quality.