-

E-mail

409070541@qq.com

-

Phone

18065929385

-

Address

No. 38-3 Xinhua Road, Siming District, Xiamen City

Xiamen Dace Environmental Protection Equipment Co., Ltd

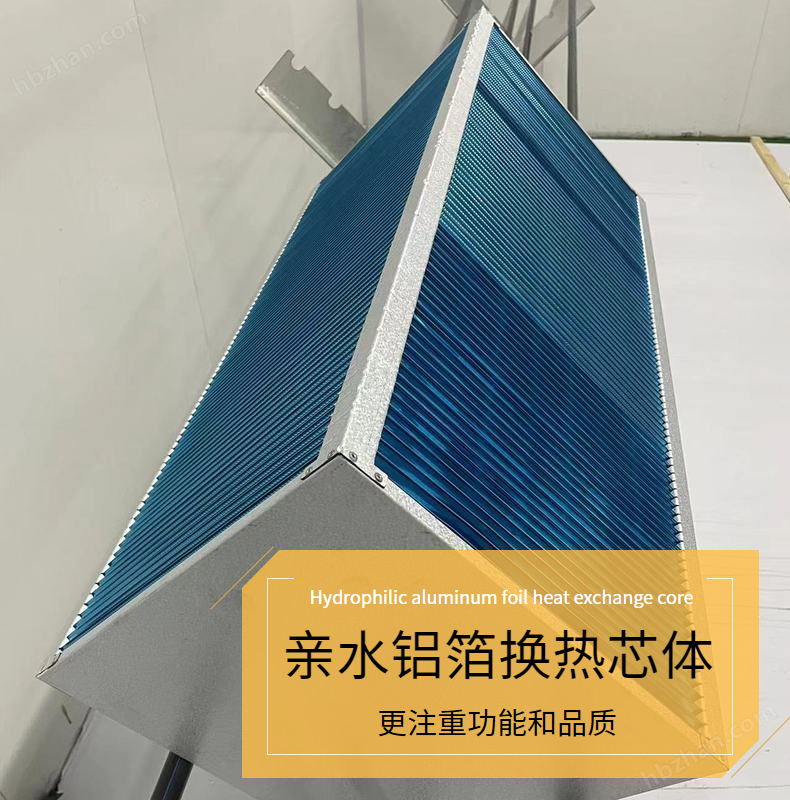

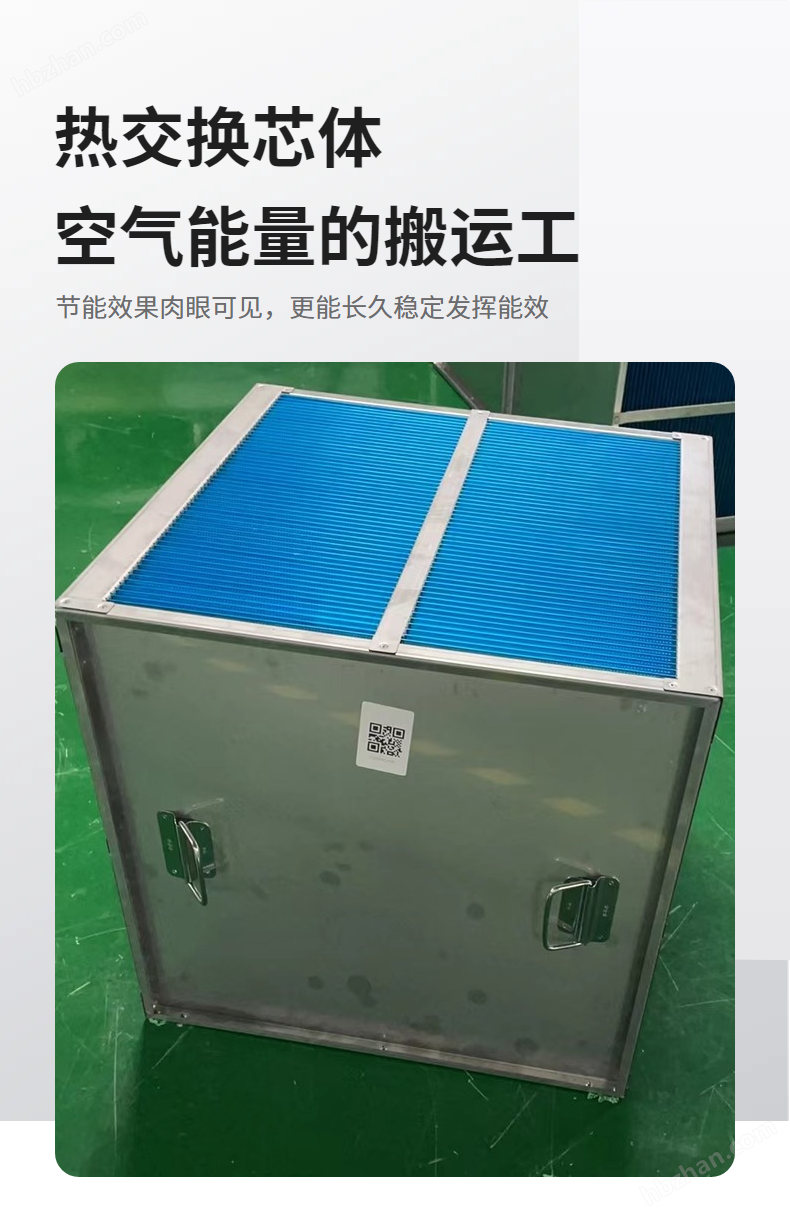

Aluminum heat exchanger waste heat recovery heat exchanger core

- Model

- Nature of the Manufacturer

- Producers

- Product Category

- Place of Origin

Aluminum heat exchanger waste heat recovery heat exchanger coreIt is the core functional component of aluminum heat exchangers, tailor-made for the industrial waste heat recovery needs of industries such as chemical, manufacturing, and metallurgy. It is a key supporting product for improving energy utilization efficiency and reducing operating costs for enterprises.

This product strictly follows industrial standards in material selection, using high-purity aviation grade aluminum as the core raw material, and is formed through multiple precision processing techniques. It not only has excellent thermal conductivity and can quickly capture waste heat resources in industrial production processes, but also has lightweight product characteristics. Compared with traditional metal heat exchange cores, the weight is reduced by more than 40%, effectively reducing the overall load of heat exchange equipment and extending its service life.

In terms of structural design,Aluminum heat exchanger waste heat recovery heat exchanger coreBy adopting an optimized honeycomb channel structure, the heat transfer area is expanded while reducing medium flow resistance, making waste heat transfer more efficient and smooth. The inner wall of the channel is specially smoothed, which not only reduces the risk of medium residue and scaling, but also facilitates subsequent cleaning and maintenance, reduces downtime for maintenance, and ensures the continuity of the production process.

The sealing performance of the product is also excellent. Through precision welding technology, the core is ensured to have no leakage under high temperature and high pressure conditions. It is suitable for different temperature ranges (-20 ℃~300 ℃) and various media environments. Whether it is acidic industrial waste gas or high-temperature industrial wastewater, it can stably perform heat transfer function.

The adaptability of this product can be customized according to different models and uses of aluminum heat exchangers, covering multiple dimensions such as size, channel density, interface specifications, etc. It matches various scenarios such as industrial heating systems, chemical reactor cooling systems, and steel plant exhaust gas treatment equipment. In practical applications, it can efficiently recover and convert industrial waste heat into usable energy for workshop heating, hot water supply, or production process reheating. On average, it can reduce enterprise energy consumption by more than 30%, significantly reduce carbon emissions, and help enterprises achieve green production transformation.

In addition, the installation process of the product is simple and convenient, without the need for complex auxiliary equipment. Only professional technicians need to follow the instructions to complete the assembly. The subsequent maintenance cost is low, making it an ideal choice for energy conservation and emission reduction in the industrial field.