-

E-mail

zhuyanyiqi@163.com

-

Phone

18653195187

-

Address

No. 288 Wuyingshan Middle Road, Huaiyin District, Jinan City, Shandong Province

Product Categories

- Liquid leakage tester

- Glass bottle heat-resistant impact tester

- Thin film heat sealing strength tester

- Thin film friction coefficient tester

- Cone joint comprehensive performance tester

- Micro leakage sealing tester

- Glass bottle impact tester

- Medical packaging tearing force tester

- Ampoule breaking force tester

- Automatic Bottle Cap Torque Tester

- Glass bottle bottom thickness and wall thickness tester

- Glass Bottle Vertical Load Tester

Jinan Zhuyan Instrument Equipment Co., Ltd

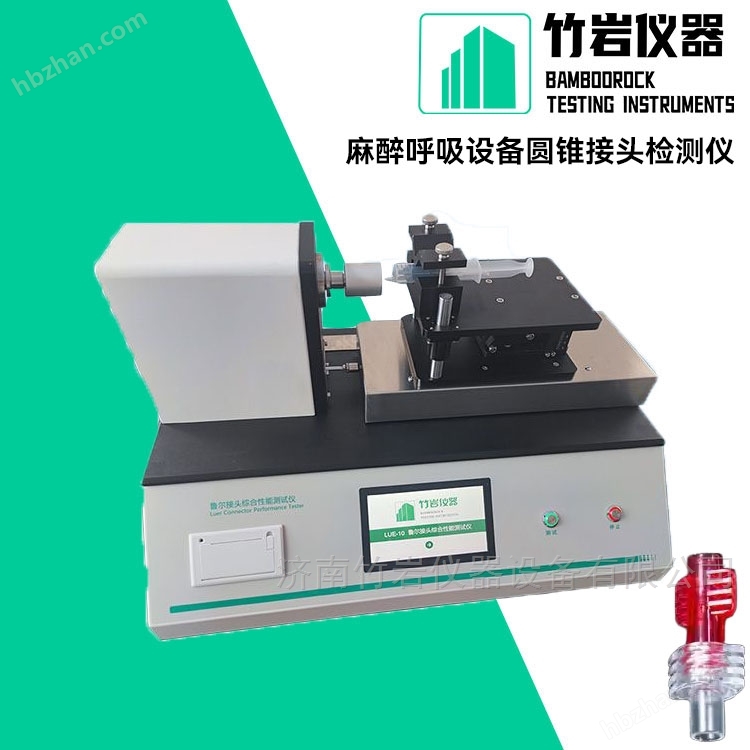

Anesthesia respiratory equipment cone joint detector

NegotiableUpdate on 02/14

- Model

- Nature of the Manufacturer

- Producers

- Product Category

- Place of Origin

Overview

It is necessary to conduct a detailed analysis of the working principle of the cone joint detector for anesthesia respiratory equipment. It mainly achieves comprehensive testing of joint performance through two key steps, namely the principle of mechanical performance testing and the data acquisition and processing method.

Product Details

Anesthesia respiratory equipment cone joint detector

Anesthesia respiratory equipment cone joint detector

In terms of mechanical performance testing, the detector uses high-precision sensors to apply various predetermined forces and torques to the conical joint, which is like simulating the various mechanical effects that the joint may experience in actual use, such as tension, pressure, and torque. Imagine that when a patient performs breathing movements during surgery, the conical joint is subjected to pressure from the breathing gas; During device movement or pipeline adjustment, there may be tension and torsion. The sensor of the detector is like a sharp "perceptron", which can accurately capture the small changes that occur in the joint when it is subjected to these external forces. Even extremely subtle displacements or deformations cannot escape its "eyes". Through these data, the key performance of the joint can be evaluated, such as whether the sealing performance is good, whether the compressive strength meets the standard, and how strong the separation of the connection is.

And data collection and processing are the "smart brain" links of the entire detection process. After the sensor collects various data of the joint during the force process, the built-in data processing module of the detector begins to function. It will quickly and accurately analyze and process the real-time collected data, like an experienced analyst extracting key information from massive amounts of data. By using complex algorithms, various performance indicators of the joint are calculated, such as specific values of sealing performance, strength levels of compressive strength, precise values of separation strength, and the magnitude of the unscrewing torque. Finally, these processed data will be compiled into a detailed test report, which clearly displays the performance of the joint in various tests, providing a visual and reliable basis for determining whether the joint meets the standards. This report is like a 'health check-up report', which doctors and equipment maintenance personnel can use to determine whether the connector can be safely used or whether further adjustments and improvements are needed.