-

E-mail

yy-valve@163.com

-

Phone

13801619288

-

Address

No. 18, Zhuangxing Industrial Park, Fengxian, Shanghai

Yuanyi Valve Co., Ltd

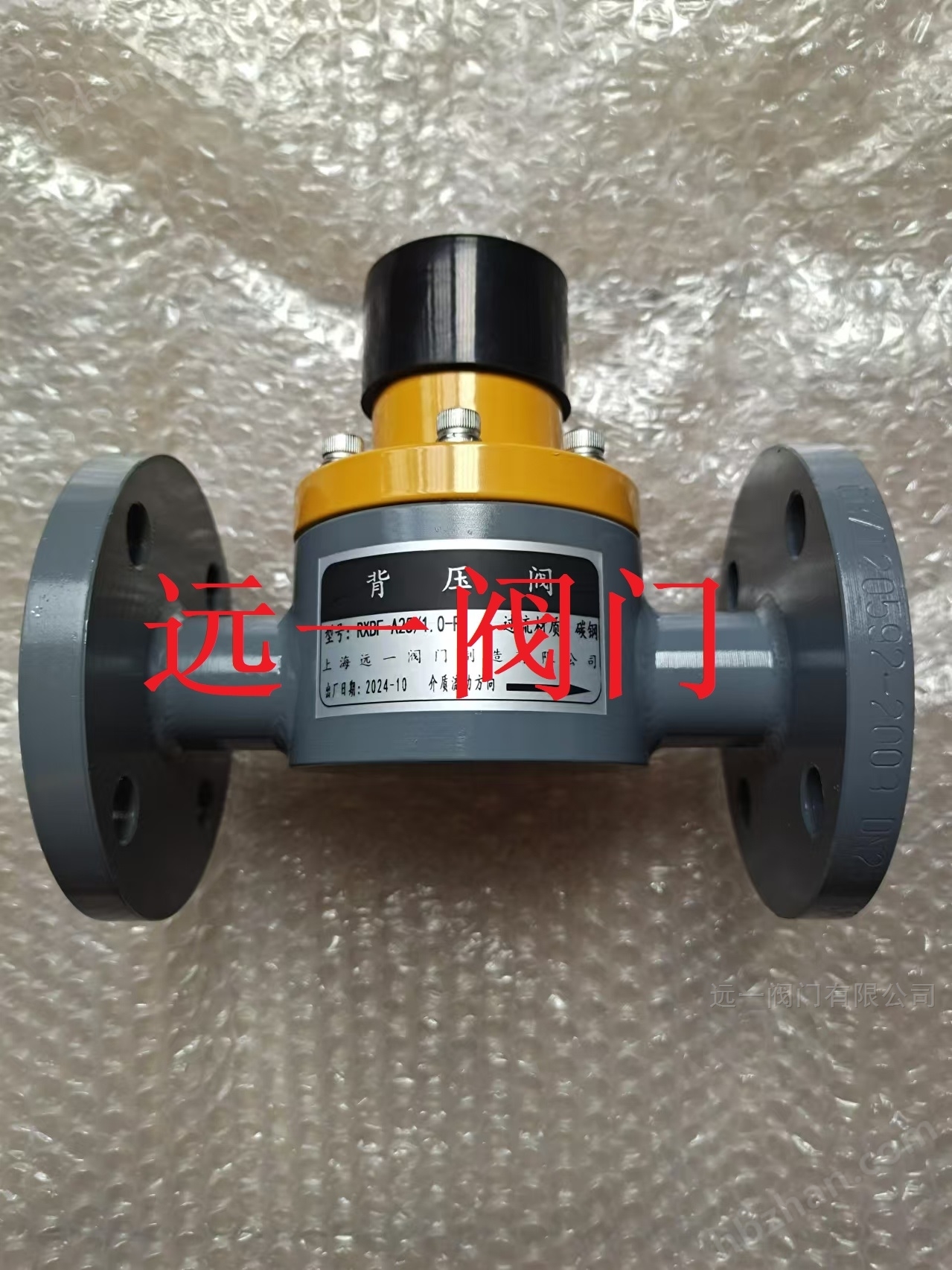

Carbon steel back pressure valve

- Model

- Nature of the Manufacturer

- Producers

- Product Category

- Place of Origin

RXBF-A6/1.0、RXBF-A8/1.0、RXBF-A10/1.0、RXBF-A15/1.0-F、RXBF-A20/1.0-F、RXBF-A25/1.0-F、RXBF-A32/1.0-F、RXBF-A40/1.0-F、RXBF-A50/1.0-F、RXBF-A65/1.0-F、RXBF-A80/1.0-F、RXBF-A100/1.0-F、RXBF-A125/1.0-F、RXBF-A150/1.0-FCarbon steel back pressure valveCast steel back pressure valves and flange back pressure valves are used to prevent liquid from flowing or siphoning under gravity. At this time, back pressure valves can reduce the flow and pressure fluctuations caused by siphoning.

Design Features

Spring diaphragm structure with adjustable pressure (see parameter table for pressure adjustment range)

The only parts that come into contact with the medium are the lower valve body and the diaphragm. The sealing area between the lower valve body and the diaphragm is processed with sealing ribs, which have good sealing effect and high sensitivity

The conventional membrane adopts EPDM lined PTFE form and is processed with cloth clamping, which has good sealing effect and high service life; Pure PTFE membrane has high temperature resistance and strong corrosion resistance

Scope of Application: TYPICAL APPROCATIONS

Chemical industry, water treatment, laboratory

Corrosive liquids, ordinary gases

Characteristic parameters:

Adjustable pressure 0-0.3MPa, 0-1.0MPa (see parameter table for details)

• Safety testing pressure: 1.5 times greater input pressure

• Applicable temperature: ordinary diaphragm -5 ℃ to+80 ℃); PTFE membrane: -5 ℃ to+80 ℃)

Material:

Lower valve body material: PVC, SS304, SS316L, PTFE, PVDF, PP, carbon steel, etc. (can be customized according to requirements)

• Membrane material: EPDM lined PTFE (composite membrane), PTFE (polytetrafluoroethylene)

Upper valve body material: PVC, carbon steel (nickel plated, blackened), 304 stainless steel, 316L stainless steel

How to choose back pressure valves on industrial pipelines?

Back pressure valves generally have two purposes:

1: Back pressure valves are used to prevent liquids from flowing by gravity (or siphoning). In this case, a pressure greater than the liquid's own pressure is generally used. To prevent liquid from flowing by itself in a 2-meter medicine tank, a back pressure valve with a pressure greater than 0.02 MPa can be used, usually 0.1 MPa.

2: A back pressure valve is used to stabilize the flow rate of a pump. For example, if the flow rate of some pumps varies greatly with pressure, a back pressure valve can be installed at the outlet of the pump to stabilize the output flow rate. In this case, the pressure of the back pressure valve is generally selected to be the actual operating pressure of the pump or slightly lower than the operating pressure of the pump.

The one-way valve on the outlet pipeline is used to prevent liquid backflow, and the back pressure valve is used to maintain a constant pressure at the pump outlet.

When purchasing a back pressure valve, please provide the following data:

1. 2. Diameter of back pressure valve 2. Pressure regulation range 3. What material is required (our company produces conventional materials such as PVC, 304 stainless steel, 316L stainless steel, please specify if other materials are needed). Better able to simultaneously inform the conveyed medium, temperature, and flow rate.

Appearance and installation dimensions of back pressure valve

| Specification Model | material | Nominal diameter (mm) | Set pressure (MPa) | size | connection method | |

| Lower valve body diameter (mm) | Total height (mm) | |||||

| RXBF-P6/1.0 | PVC | 6 | 0.1-1.0 | 64.7 | 82 | Rc1/8” |

| RXBF-P8/1.0 | PVC | 8 | 0.1-1.0 | 64.7 | 87 | Rc1/4” |

| RXBF-P10/1.0 | PVC | 10 | 0.1-1.0 | 64.7 | 89 | Rc3/8” |

| RXBF-P15/1.0 | PVC | 15 | 0.1-1.0 | 64.7 | 94 | Rc1/2” |

| RXBF-P20/1.0-N | PVC | 20 | 0.1-1.0 | 64.7 (small valve body, suitable for pumps up to 250L/h) | 104 | Rc3/4” |

| RXBF-P20/1.0 | 87 | 123 | ||||

| RXBF-P25/1.0 | PVC | 25 | 0.1-1.0 | 87 | 128 | Rc1” |

| RXBF-P32/1.0 | PVC | 32 | 0.1-1.0 | 117 | 175 | Rc1+1/4” |

| RXBF-P40/1.0-N | PVC | 40 | 0.1-1.0 | 117 (small valve body, suitable for pumps up to 2500L/h) | 185 | Rc1+1/2” |

| RXBF-P40/1.0 | 137 | 240 | ||||

| RXBF-P50/1.0 | PVC | 50 | 0.1-1.0 | 167 | 260 | Rc2” |

| RXBF-P65/1.0 | PVC | 65 | 0.1-1.0 | 177 | 325 | Rc2+1/2” |

| RXBF-P80/0.6 | PVC | 80 | 0.1-0.6 | 230 | 420 | Rc3” |

| RXBF-P100/0.6 | PVC | 100 | 0.1-0.6 | 250 | 430 | Rc4” |

| RXBF-S6/1.0 | SUS304/316L | 6 | 0.1-1.0 | 64.7 | 82 | Rc1/8” |

| RXBF-S8/1.0 | SUS304/316L | 8 | 0.1-1.0 | 64.7 | 87 | Rc1/4” |

| RXBF-S10/1.0 | SUS304/316L | 10 | 0.1-1.0 | 64.7 | 89 | Rc3/8” |

| RXBF-S15/1.0 | SUS304/316L | 15 | 0.1-1.0 | 64.7 | 94 | Rc1/2” |

| RXBF-S20/1.0-N | SUS304/316L | 20 | 0.1-1.0 | 64.7 (small valve body, suitable for pumps up to 250L/h) | 104 | Rc3/4” |

| RXBF-S20/1.0 | 87 | 123 | ||||

| RXBF-S25/1.0 | SUS304/316L | 25 | 0.1-1.0 | 87 | 128 | Rc1” |

| RXBF-S32/1.0 | SUS304/316L | 32 | 0.1-1.0 | 117 | 175 | Rc1+1/4” |

| RXBF-S40/1.0-N | SUS304/316L | 40 | 0.1-1.0 | 117 | 185 | Rc1+1/2” |

| RXBF-S40/1.0 | 137 | 240 | ||||

| RXBF-S50/1.0 | SUS304/316L | 50 | 0.1-1.0 | 167 | 260 | Rc2” |

| RXBF-S65/1.0 | SUS304/316L | 65 | 0.1-1.0 | 177 | 325 | Rc2+1/2” |

| RXBF-S80/0.6 | SUS304/316L | 80 | 0.1-0.6 | 225 | 420 | 3 "flange type |

| RXBF-S100/0.6 | SUS304/316L | 100 | 0.1-0.6 | 240 | 430 | 4 "flange type |