-

E-mail

409070541@qq.com

-

Phone

18065929385

-

Address

No. 38-3 Xinhua Road, Siming District, Xiamen City

Xiamen Dace Environmental Protection Equipment Co., Ltd

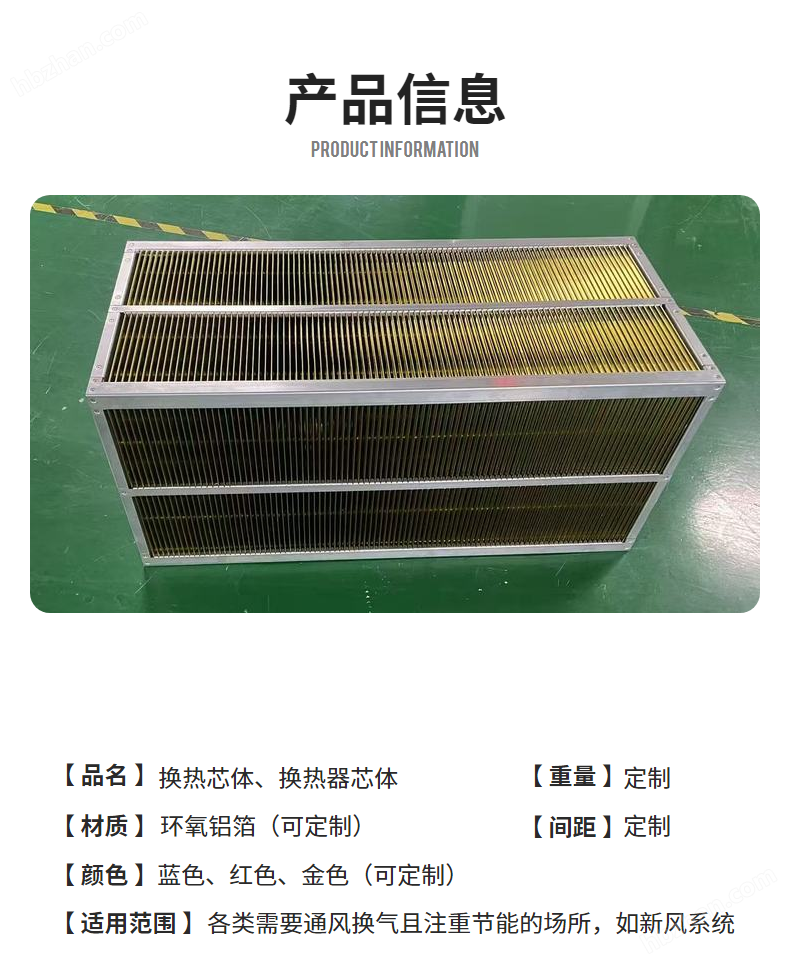

Chemical reaction kettle precooler plate fin heat exchanger core

- Model

- Nature of the Manufacturer

- Producers

- Product Category

- Place of Origin

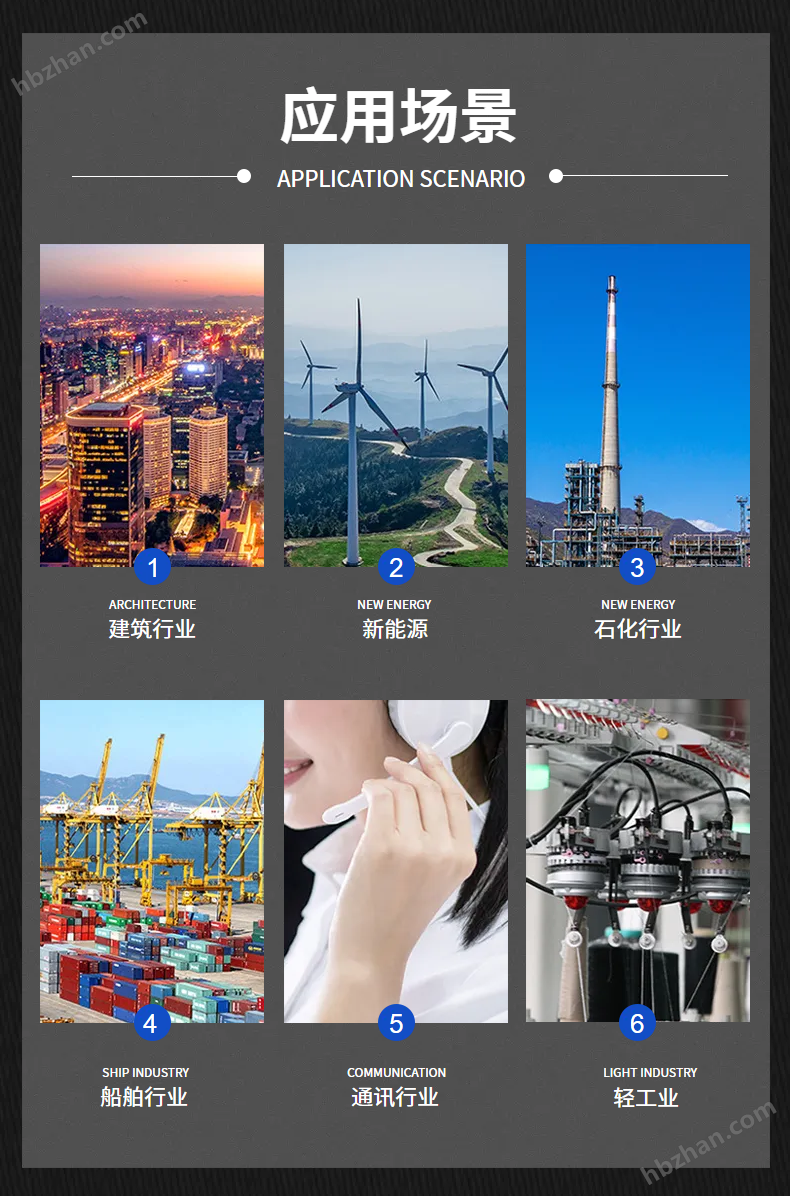

Chemical reaction kettle precooler plate fin heat exchanger coreIt is the core functional component of the precooler, designed specifically for cooling pretreatment scenarios in chemical reaction vessels. It is compatible with chemical processes such as synthetic ammonia and ethylene cracking, and has become a key supporting product in chemical production due to its corrosion resistance, high pressure, and efficient temperature control characteristics.

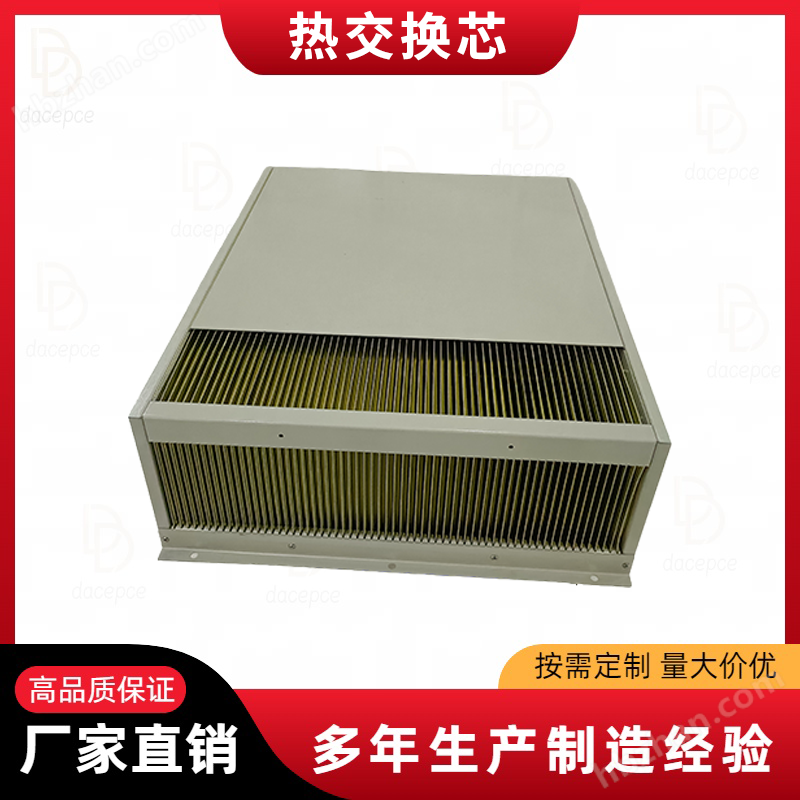

The core material of the product is 316L stainless steel. The addition of molybdenum element further enhances its resistance to pitting and crevice corrosion, and can resist the erosion of organic acids, inorganic acids, and chloride ions in the reaction vessel medium. The carbon content is ≤ 0.03%, effectively reducing the risk of intergranular corrosion. The working pressure can reach over 4.0MPa, meeting the requirements of high-pressure chemical working conditions.

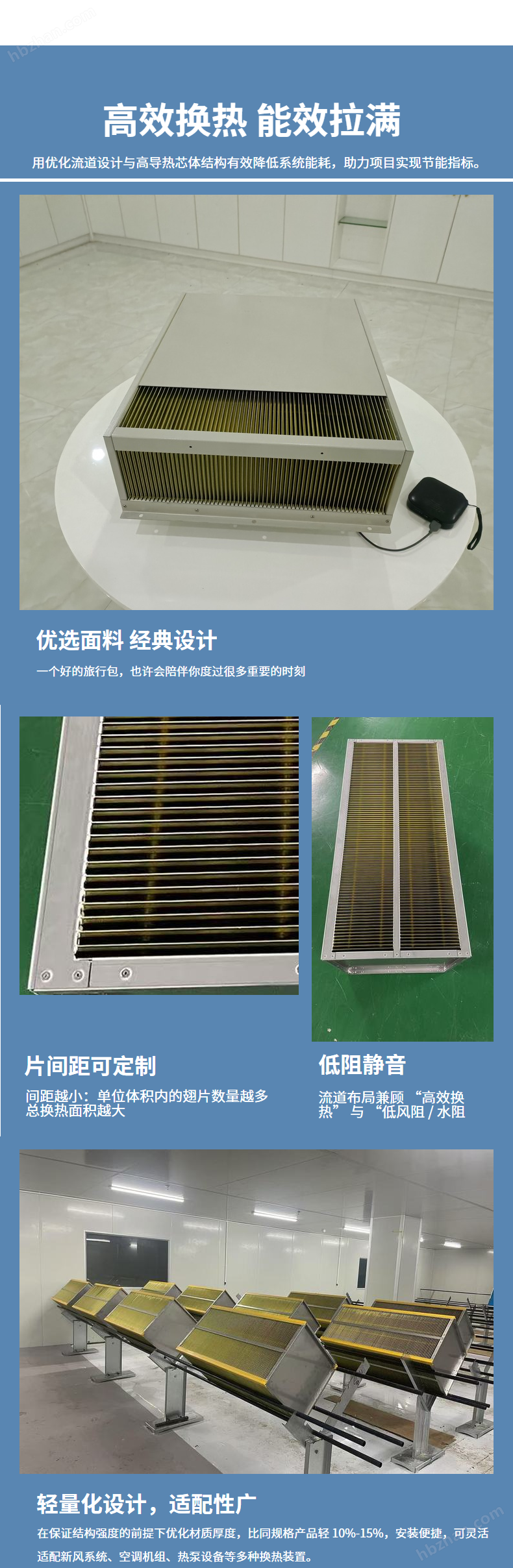

Adopting a classic plate fin structure design, consisting of partitions, corrugated fins, and sealing strips, the fins are tightly integrated with the base tube through integral rolling. The heat transfer area is increased by more than 40% compared to traditional tube heat exchange cores, and the heat transfer efficiency is greatly enhanced, which can quickly reduce the medium temperature to the preset range.

The internal flow channel design of the core is reasonable, with partitioned flow of cold and hot media, low flow resistance and uniform heat transfer. The temperature control accuracy can reach ± 1 ℃, avoiding the impact of reaction temperature fluctuations on product yield. The temperature resistance range covers -40 ℃~200 ℃, suitable for the pre cooling needs of different chemical reactions.

Chemical reaction kettle precooler plate fin heat exchanger coreSupport customized production, adjust core size, fin spacing, and interface specifications according to reaction vessel processing capacity and working pressure, and adapt to various chemical reaction vessel pre cooling devices.

The installation process is simple and convenient, without the need for complex auxiliary tools. Only professional personnel need to fix it according to the positioning requirements. The subsequent maintenance cost is low, and regular cleaning of impurities and scaling in the flow channel can ensure stable operation. The plate fin structure is compact, with high space utilization and does not occupy too much production space.

In practical applications, it can effectively reduce the energy consumption of refrigeration systems, reduce energy waste in the cooling process of reaction vessels, and ensure that chemical reactions proceed within a stable temperature range, improving the yield of light hydrocarbons by more than 1.5%. The product's various performance indicators meet the standards of the chemical industry, and its corrosion and pressure resistance have been rigorously tested. Long term operation without leakage risks provides reliable support for safe and efficient chemical production.