-

E-mail

liuyanhe@zhderx.com

-

Phone

13005602816

-

Address

Zhuhai New Olin Technology Park

- Acetone wastewater low-temperature evaporation treatment equipment

- Sodium sulfate mixed salt solution dryer

- Polyethylene glycol wastewater concentration equipment

- Dimethyl sulfoxide wastewater treatment equipment

- Organic solvent wastewater concentration treatment equipment

- Wastewater phosphoric acid recovery equipment

- Mother liquor drying machine

- Electroplating wastewater evaporation crystallization equipment

Zhuhai Derunxin General Machinery Co., Ltd

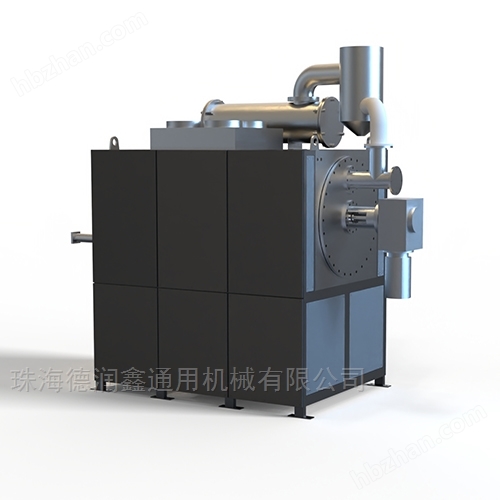

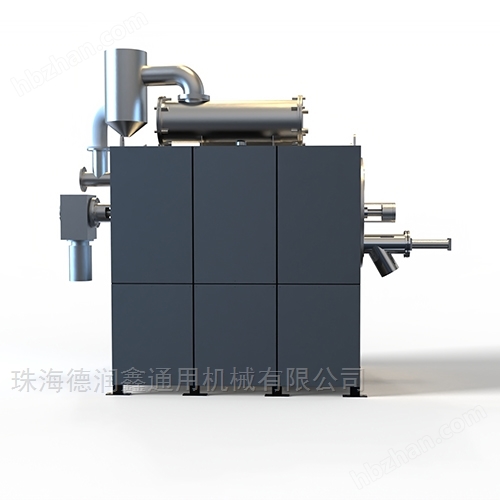

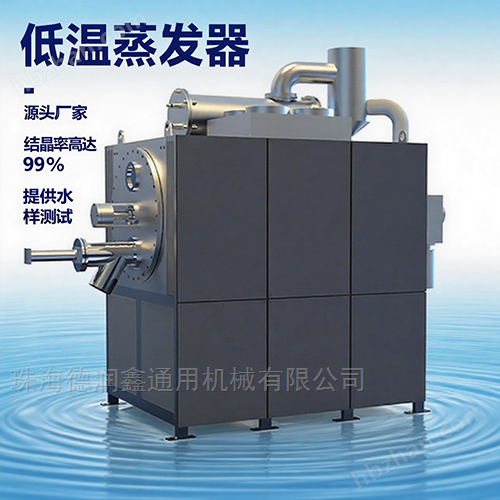

Dimethyl sulfoxide wastewater treatment equipment

- Model

- Nature of the Manufacturer

- Producers

- Product Category

- Place of Origin

working principle

Dimethyl sulfoxide wastewater treatment equipmentFirstly, pretreatment of dimethyl sulfoxide wastewater is carried out to remove suspended particles and colloidal impurities through precision filtration, in order to avoid equipment blockage in the future. The pre treated wastewater enters a specially designed evaporation system, which utilizes the boiling point difference between dimethyl sulfoxide and water for evaporation and separation under specific temperature and vacuum conditions. Due to the high boiling point of dimethyl sulfoxide, by precisely controlling the evaporation conditions, the water is first evaporated into steam and then condensed into reusable or further processed water in the condensation system; Subsequently, the temperature is increased to evaporate dimethyl sulfoxide, and the vapor is condensed into a liquid state through a dedicated condensing device to achieve the recovery of dimethyl sulfoxide. For water that still contains trace amounts of dimethyl sulfoxide after evaporation, it enters the deep treatment unit and is treated using adsorption, oxidation, and other technologies to ensure that the water quality meets the standards.

Features of the equipment

Efficient recovery of DMSO with strong economic viability:Dimethyl sulfoxide wastewater treatment equipmentDesign a recovery process based on the characteristics of dimethyl sulfoxide, with a recovery rate of over 95%. The recovered dimethyl sulfoxide has high purity (usually above 99%) and can be directly reused in production, significantly reducing the raw material cost of enterprises.

Deep processing ensures compliance with standards:By combining multi-stage processes such as pretreatment, evaporation separation, and deep treatment, dimethyl sulfoxide and other impurities in wastewater can be effectively removed. The concentration of dimethyl sulfoxide in treated wastewater can be reduced to below 10mg/L, meeting emission standards and safe for discharge or reuse.

Material adaptation, corrosion resistance and durability:The components in contact with wastewater are made of special corrosion-resistant materials (such as 316L stainless steel, PTFE, etc.), which can withstand the chemical corrosion of dimethyl sulfoxide, extend the service life of the equipment, and reduce maintenance costs.

Intelligent control, easy to operate:Equipped with a PLC intelligent control system, it can monitor key parameters such as temperature, pressure, and flow in real time, achieving fully automatic operation, including feeding, evaporation, separation, and recovery processes, reducing manual intervention and ensuring stable processing results.

Safe design, reliable operation:Equipped with safety systems such as over temperature alarm, pressure protection, and explosion-proof devices, safety optimization is carried out based on the characteristics of dimethyl sulfoxide to avoid safety accidents during the processing and ensure stable operation of the equipment.

Energy saving and consumption reducing, environmentally friendly:By adopting efficient heat exchange technology and optimized evaporation process, energy consumption is reduced, and there is no secondary pollution such as exhaust gas and waste residue during operation, which meets environmental protection requirements.

Classic Case

A certain pharmaceutical enterprise's dimethyl sulfoxide wastewater treatment project: The enterprise generates 30m ³ of dimethyl sulfoxide wastewater per day, with a dimethyl sulfoxide concentration of about 8000mg/L. After adopting this treatment equipment, the recovery rate of dimethyl sulfoxide reached 96%, with a daily recovery of about 0.23 tons of dimethyl sulfoxide with a purity of 99.2%. The annual cost savings of raw materials were about 1.2 million yuan. The concentration of dimethyl sulfoxide in the treated wastewater was reduced to 8mg/L, which met the standard for discharge and passed the strict acceptance of the environmental protection department.

DMSO wastewater treatment project of a certain chemical enterprise: Targeting the mixed wastewater containing dimethyl sulfoxide and a small amount of other organic solvents (COD about 20000mg/L), the equipment achieves efficient recovery of dimethyl sulfoxide through targeted processes, with a recovery rate of 95%. After treatment, the COD of the wastewater is reduced to below 150mg/L, meeting the reuse standard. The annual reduction of wastewater treatment costs and raw material procurement costs is about 900000 yuan, solving the environmental protection problem of the enterprise.