-

E-mail

339515831@qq.com

-

Phone

18052529916

-

Address

No. 65 Runyuan Road, Benniu Industrial Park, Changzhou City, Jiangsu Province

Product Categories

Jiangsu Kelsen Environmental Protection Technology Co., Ltd

Explosion proof medium pressure blower industrial 5.5KW gas conveying fan

NegotiableUpdate on 02/20

- Model

- Nature of the Manufacturer

- Producers

- Product Category

- Place of Origin

Overview

Explosion proof medium pressure blower industrial 5.5KW gas conveying fan is an explosion-proof fan product with explosion-proof performance that meets relevant electrical standards; It is a motor structure that does not generate arcs, sparks, or dangerous high temperatures under normal operating conditions, and takes some mechanical, electrical, and thermal protection measures to further avoid the danger of arcs, sparks, or high temperatures under normal or recognized overload conditions, thereby ensuring its explosion-proof safety. So the motor that meets the explosion-proof requirements adopts the explosion-proof level DIIBT4 protection level IP55 second level explosion-proof motor.

Product Details

Explosion proof medium pressure blower industrial 5.5KW gas conveying fanCharacteristics:

1. It has dual functions of blowing and suction, and can be used for both suction and blowing;

2. Running with little or no oil, the output air is clean;

3. Compared to centrifugal fans and medium pressure fans, their pressure is much higher, often more than ten times that of centrifugal fans;

4. If the pump body is die cast as a whole and shockproof mounting feet are used, the requirements for the installation foundation are also very low. It can even operate normally without fixing the feet, which is very convenient and saves installation costs and installation cycles;

5. Compared to similar fans, its operating noise is lower, just like the RHG introduced vortex fan:

6. Maintenance free use; Its consumable parts are only two bearings, which basically do not require maintenance within the warranty period;

7. The mechanical wear of EX explosion-proof fans is very small because there are no other mechanical contact parts besides the bearings, so the service life is naturally very long. As long as it is under normal operating conditions, there is no problem for 3-5 years;

8. Easy to install and use!

9. The overall material is made of aluminum alloy, and the motor is an explosion-proof motor, which will never produce sparks due to friction. It is more reassuring to use and has better explosion-proof performance

Preparation for start-up and precautions before start-up: Before start-up, the following checks and confirmations must be carried out during trial operation after installation and alignment Attention should be paid to the following matters and handled with caution.

1) Confirm whether the specifications of the fan and prime mover meet the ordering requirements Are all attachments prepared.

2) Check if the power supply (voltage, switches, etc.) and wiring meet electrical requirements. Is the wiring accurate.

3) Check whether there is condensation water, dust, and other debris left in the fan and pipeline. If there is. It is necessary to clean it thoroughly to prevent major malfunctions when starting the ventilation fan.

4) Confirm whether the anchor bolts, fan body, accessories and accessories, and connecting parts of the connecting pipelines are tightened as required

5) Confirm if all components are aligned. For fans with couplings or belt drives Check the coupling or pulley Is the installation of V-belt reliable Whether the coaxiality between the fan shaft and the motor shaft meets the requirements.

6) Check if the lubricating oil (grease) of the night bearing is sufficient and intact. If there is an oil supply device, first run it for 2 hours to check if the oil temperature and pressure on the side are normal.

7) For fans with water-cooled bearings Check if the water supply condition of the cooling water pipeline is normal.

8) Manually rotate the fan shaft and prime mover shaft Check if the rotation is smooth Confirm that there are no abnormalities.

9) Rotate the prime mover separately Confirm the rotation direction of the prime mover and the fan rotation direction * Simultaneously confirm that there are no abnormal conditions on the prime mover side.

10) For fans with drive Check if the tension of each V-belt at night is *.

11) When using couplings that require lubricating oil lubrication, confirm whether the injected lubricating oil is qualified.

12) Confirm whether the regulating door or valve is open or closed, and whether there is any abnormal action. The inlet and outlet regulating valves of the fan Centrifugal is fully closed When the axial flow is fully open, the starting load is minimized

13) For fans with strong side oil supply devices with bearings It should be confirmed whether the fuel level of the fuel tank, the fuel tank and oil pipeline are clear and unobstructed, the rotation direction of the oil pump, the water supply and drainage mechanism of the oil cooler, and the interlocking mechanism are normal

14) Additionally Necessary training should be provided to the relevant operators in advance to enable them to handle sudden situations when the fan starts operating Be able to quickly make corresponding and correct actions according to the instructions of the operation commander

Explosion proof medium pressure blower industrial 5.5KW gas conveying fanStructural Description

2.1 The explosion-proof structure of the electric fan has Ex dI, Ex dIICT4, and Ex dIIBT4.

2.2 The protection level of the main body shell of the electric fan is IP55.

The cooling method of the electric fan is IC411.

2.4 The insulation level of the electric fan is F level, and the stator winding has a large temperature rise margin and a long service life.

The 2.5 electric fan has a cylindrical shaft extension, which is driven by a coupling or gear.

2.6 The stator winding of the electric fan adopts high-strength enameled round copper wire, which is vacuum pressurized and immersed in paint to form a complete whole. The winding and insulation have good electrical, mechanical, moisture-proof performance and thermal stability.

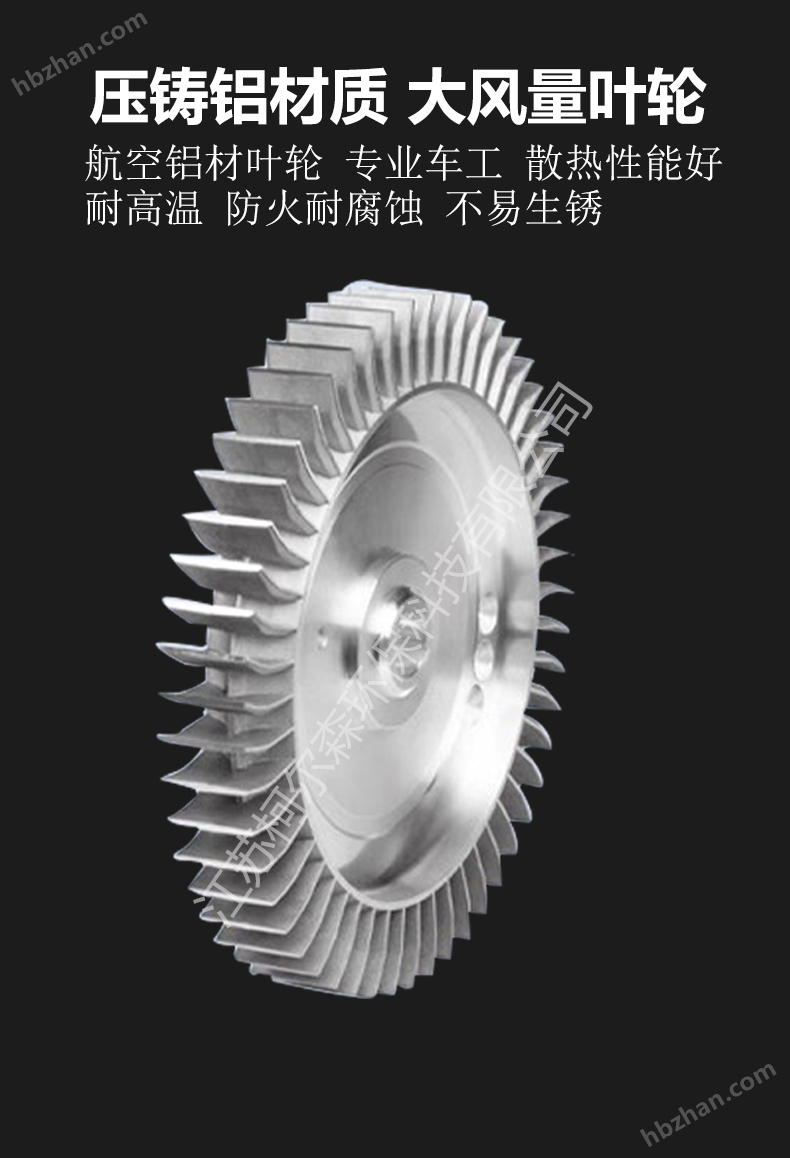

2.7 The rotor of the electric fan adopts a cast aluminum structure, and the rotor has undergone dynamic balance verification. The motor runs smoothly, with low vibration and noise.

2.8 The stator and rotor blades of the electric fan are made of high-quality electrical silicon steel sheets with high magnetic conductivity and low loss, resulting in low motor loss and high efficiency.

2.9 The bearings for the electric fan are selected as low vibration and low-noise bearings for the motor. Double sided sealed bearings are used for machine seat sizes 160 and below, and waveform spring washers are installed at the shaft extension end to provide moderate pressure against the bearings and effectively suppress the vibration and noise generated during motor operation. For machine seat sizes 180 and above, inner and outer cover structures are used, and retaining rings are used for axial fixation at the bearing locations to effectively prevent axial movement of the motor rotor.

For the safe and reliable operation of electric motors, the bearing structure of motors with a base size of 180 and above is equipped with an oil injection device. For motors with a base size of 250 and above, a position for bearing temperature monitoring sensing elements is reserved.

2.10 Motor fan and fan cover: Motors with a base size of 280 and below use anti-static plastic fans, which have low rotational inertia and low loss. Motors with a base size of 315 and above use cast aluminum or steel plate welded fans, which are lightweight and strong. The entire series of fans are connected to the shaft with critical connections, ensuring reliable operation. The wind cover is made of steel plate structure, which provides a large ventilation area while preventing the intrusion of foreign objects of a certain size, ensuring smooth air flow.

Selection of medium voltage explosion-proof fan:

The fan is a medium pressure fan, also known as a through type blower, not a high-pressure fan. Remember this.

After knowing the suction volume and pressure, you can make a selection based on the performance table

The standard voltage is 3-phase 380 VOLTS. If different voltages are required, our company can also provide them

A、 The selection of fan pressure and air volume, such as how many cubic meters per minute and how many pascals of pressure are required.

Explosion proof fans have three phases, such as FB-3, so when selecting, it is important to inform the salesperson to avoid making the wrong choice and causing inconvenience.

B、 If you know the power of the fan, it's good. If you don't know, you can choose based on the air volume and ask the salesperson to recommend it.