-

Phone

18961575209384137749

-

Address

Room 106, Building 3, China Yixing International Environmental Protection City, No. 66 Far East Avenue, Gaocheng Town, Yixing City

Yixing Dinghai Environmental Protection Technology Co., Ltd

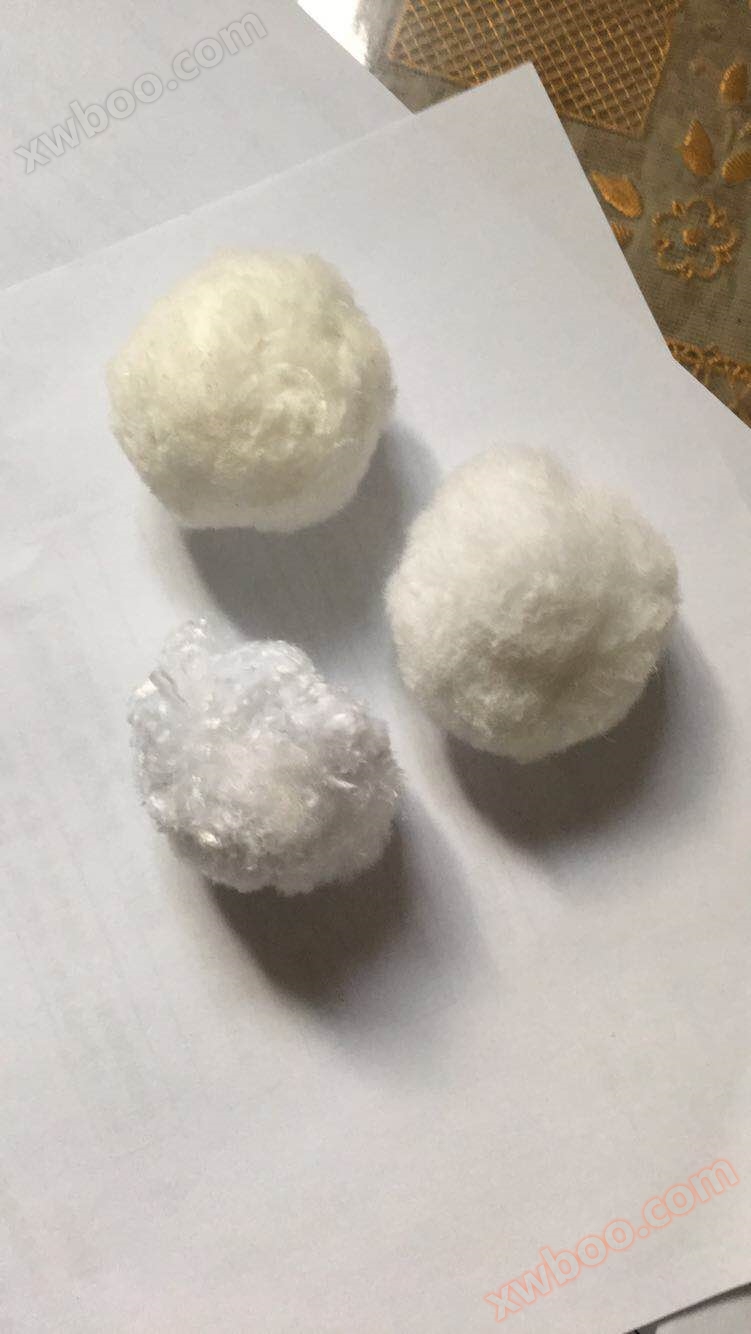

Fiber ball filler

- Model

- Nature of the Manufacturer

- Producers

- Product Category

- Place of Origin

Product Introduction:

Filtration is the most effective means of removing suspended solids from water, and it is an indispensable process in water treatment processes that require high effluent quality. Due to limited water sources that cannot meet the continuous growth of water consumption, sewage must be reused, and water source pollution is becoming increasingly serious. The demand for deepening sewage treatment procedures and protecting the environment is growing. With the development of industry, filtration has been widely used not only for water treatment, but also for high standard water treatment and sewage treatment in industries such as electronics, petroleum, chemical, and power, and has promoted the research and development of new filtration technologies.

Feature:

Flexible media can be compressed and easily restored; The ideal filter layer is loose and dense;

Moderate specific gravity makes it easy to backwash and consumes less water; Chemical fiber material is wear-resistant and corrosion-resistant;

Strong adaptability, versatile specifications, and wide applications; Significant benefits without medication and high filtration rate;

The equipment is compact, occupies less space, and has higher efficiency.

Performance:

| intensity | Moisture absorption rate | relative | specific gravity | thermal performance | Nairi | acid resistance | alkali resistance | wear resistance | Microbial resistance |

| Wet strength | Optical property | ||||||||

| 4-6 grams/dan is twice as high as cotton and three times higher than wool | 0.4-0.6% | 100% | 1.38 grams per centimeter3 | Softening point: 238-240 ℃ | excellent | 35%HCL | 10%NaOH2 | excellent | Not moldy |

| (20℃RH65%) | Melting point: 255-260 ℃ | 75%H3SO4 | 28%NH3H2O | Not boring | |||||

| 65%HNO3 | Regarding strength | ||||||||

| Regarding strength | no impact | ||||||||

| no impact |

Fiber bundle filter material

Fiber bundle filter material is a new type of filler developed and researched by our factory in recent years. This product uses high-quality acrylic and polyester fibers as raw materials. Due to its use of a large number of biological groups attached to its surface and oxygenation, it repeatedly comes into contact with sewage, intercepting small suspended solids that are difficult to precipitate and remove, and degrading organic matter to achieve purification. The filter speed is 4-4.5 times higher than that of quartz sand filter material. Easy to backwash and regenerate, capable of automated management, with a general filtration rate of 35m/h, coarse filtration inlet water of 120mg/L, effluent SS ≤ 5mg/L, fine filtration inlet water of 25mg/L, effluent ≤ 2mg/L. Due to its special process, it can be quickly replaced and repaired. Currently, it is widely used for high standard water use, circulation, side filtration, and wastewater recycling in industries such as power, oil fields, chemical, metallurgical, and electronics.

理化性能:

| appearance | Bundle like structure | void ratio | 98% |

| Fiber diameter | 20-50 um | filtration rate | 35-85m/h |

| Fiber length | 15-25㎜ | Cut off sediment volume | 8㎏/m3 |

| Coarse bundle | 100-150㎜ | surface area | 3500㎡/m3 |

| Bundle length | Customized according to user requirements for lengths over 1m | Filling density | 50-70㎏/m3 |