-

E-mail

xinweiduguolv@163.com

-

Phone

15030659779

-

Address

Bazhou City, Hebei Province

Langfang New Latitude Filter Equipment Co., Ltd

Filter element (dehydration steam water separator) 670 * 2750

- Model

- Nature of the Manufacturer

- Producers

- Product Category

- Place of Origin

Filter element (dehydration steam water separator) 670 * 2750Methods and techniques

Dehydration of filter cartridge is an important technology in the filtration process, which involves removing water or other liquid impurities from the filter cartridge to improve filtration efficiency and extend the service life of the filter cartridge. The following are several common methods and techniques for filter dehydration:

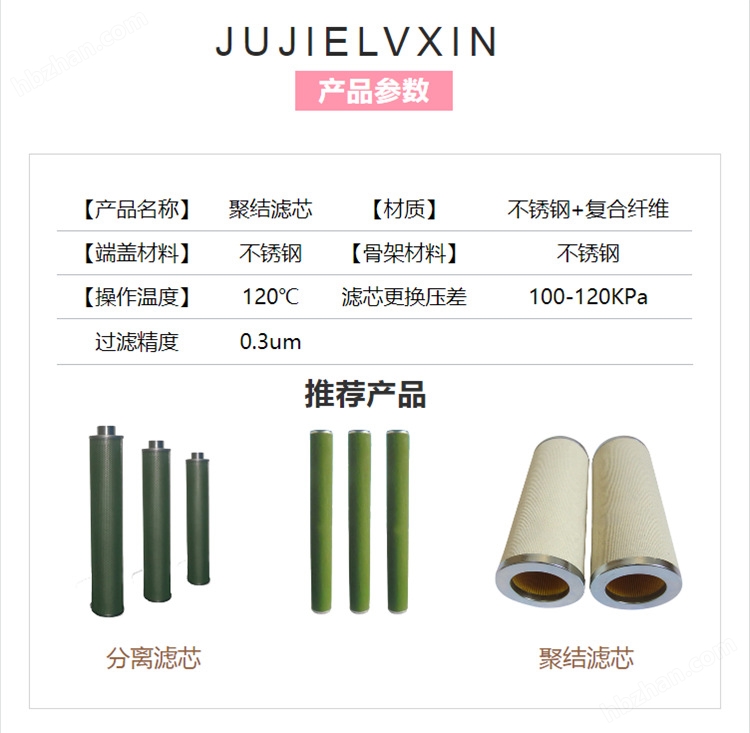

1. Agglomeration dehydration filter element

Agglomeration dehydration filter is a type of filter with outstanding agglomeration function, which can achieve a filtration accuracy of 0.1 μ m. Its working principle is to use ultrafine fibers to capture droplets in oil, water, and other liquids. Through the action of three filtering mechanisms: inertial collision, dispersion blocking, and direct blocking, small droplets aggregate into larger droplets, which settle to the bottom of the container under gravity.

2. Mechanical pressing and dehydration

Mechanical pressing and dehydration is a low-energy and high-efficiency dehydration method. Its energy consumption is only 0.05 times that of thermal dehydration, which is very suitable for the current energy shortage needs. The squeezing pressure is directly proportional to the tension of the filter belt and inversely proportional to the radius of the squeezing rollers. Therefore, the arrangement of the squeezing rollers is arranged in order of diameter from large to small to form a pressure gradient from small to large.

3. Hydraulic dehydration

Hydraulic dewatering, also known as hydraulic pressing, is a process that uses traditional filter press operation to fill the filter chamber with filter cake while continuing to feed slurry. At this time, the direction of the filtrate flow changes, which inevitably causes changes in the hydraulic pressure acting on the filter cake layer and the compression pressure distribution of the filter cake, causing the filter cake to continue to be compacted and the moisture content to decrease, known as the filtration compaction phenomenon.

4. Vacuum suction and removal

Vacuum suction is a method of removing liquid from the pores of a filter cake by replacing the filtrate with another fluid that is immiscible with the filtrate. The commonly used displacement fluid is air or other gases. This method can be used on many types of filter presses and vacuum filters, usually after the filtration or washing operation is completed.

Filter element (dehydration steam water separator) 670 * 27505. Large centrifugal dewatering machine

A large centrifugal dehydrator is a device used for dehydrating plastic filter cartridges. It adopts a stainless steel high-speed spin dryer and is suitable for industries such as food, textile, pharmaceutical, chemical, and coal. This dehydrator can significantly reduce the moisture in the material in a short period of time, improving cleaning efficiency.

In summary, various filter dehydration methods and technologies have their advantages and applicable scenarios. In practical applications, suitable dehydration methods can be selected according to needs.