-

E-mail

2881068607@qq.com

-

Phone

18721098757

-

Address

No. 253 Yulu Road, Jiading District, Shanghai

Ankerui Electric Co., Ltd

Green Factory Light Storage Charging Network Integrated Control System

- Model

- Nature of the Manufacturer

- Producers

- Product Category

- Place of Origin

Overview-Green Factory Light Storage Charging Network Integrated Control System

In the current acceleration towards the "dual carbon" goal, the industrial manufacturing sector, as the main source of energy consumption and carbon emissions, is facing increasingly strict environmental policy constraints and challenges from green supply chain standards. The traditional extensive development model of high energy consumption and high emissions is no longer able to bring sustained benefits to industrial manufacturing enterprises, while the integrated system of source grid load storage (i.e. the coordinated optimization system of power supply, power grid, load and energy storage) has opened up a new path for enterprises to move towards green transformation. By effectively integrating renewable energy resources, smart grid interactive technology, flexible load adjustment capabilities, and energy storage solutions, industrial manufacturing enterprises can not only significantly reduce their carbon footprint, but also significantly enhance their competitiveness in the market while improving energy utilization efficiency. This article aims to deeply analyze how to use the integrated system of source, network, load, and storage to help enterprises achieve a leap in green development, and propose a series of practical solutions.

1、 Modern green factory power regulation

The challenge of grid adaptability is intensifying: the design core of traditional grids focuses on centralized power generation mode, while the distributed characteristics of new energy put forward higher flexibility and adaptability requirements for the grid. The potential changes in power flow and voltage distribution caused by the integration of new energy into the grid undoubtedly pose a serious challenge to the stable operation of the grid.

The instability and intermittency dilemma of new energy: New energy sources such as wind and solar have significant fluctuations and discontinuities, leading to extremely unstable power supply, which poses a challenge to the power energy system of factories. The randomness of new energy generation makes grid scheduling even more difficult, leading to a significant increase in grid load fluctuations.

Efficiency bottleneck of power energy management system: Currently, the accuracy and practical value of electricity data collection still need to be significantly improved, and the lack of detailed electricity basic data seriously restricts the efficiency of energy management systems. In addition, the high cost of energy management construction and the difficulty of building a collection network make the implementation of energy-saving and emission reduction plans difficult.

Shortcomings in equipment monitoring and maintenance: delayed warranty response for equipment damage, inadequate tracking of repair services, incomplete feedback mechanisms, resulting in overall low efficiency. More seriously, the lack of monitoring and maintenance makes it difficult to detect abnormal energy losses, such as electricity theft and water leakage, in a timely manner, resulting in a large amount of unnecessary energy losses.

The dual challenge of energy consumption analysis and prediction: With a large time span, the difficulty of energy consumption analysis increases sharply, and energy consumption prediction becomes increasingly difficult. In addition, the statistics of product unit consumption and energy consumption costs lack sufficient precision, which cannot provide strong support and guarantee for production and energy conservation and emission reduction.

Unreasonable energy allocation strategy: The current energy allocation may not fully take into account the actual energy consumption of each process and equipment, resulting in serious energy waste. At the same time, the lack of energy network models or energy control models for real-time monitoring and early warning makes the optimization of energy distribution more difficult.

IIGreen Factory Light Storage Charging Network Integrated Control System

2.1 Solution Composition

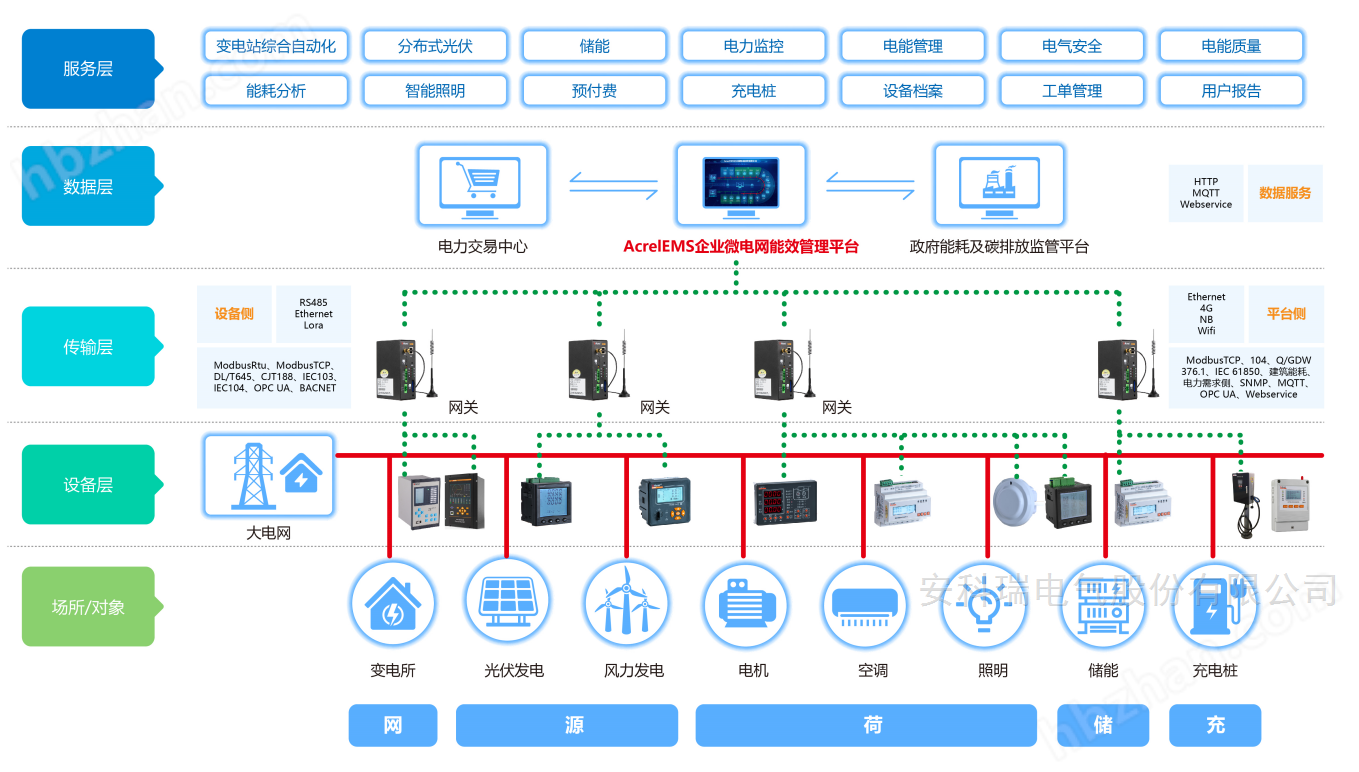

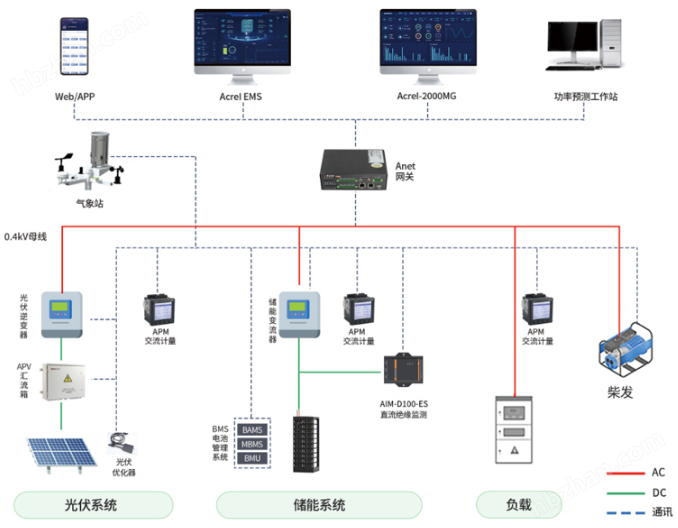

Power side: including power generation facilities for various renewable energy sources (such as wind power, photovoltaics) and traditional energy sources (such as thermal power, hydropower). These power sources are interconnected through smart grids to achieve complementary and optimized energy configuration.

Grid side: As a carrier of energy transmission, the smart grid has high flexibility and interactivity. It can monitor and control the flow of energy in real time, ensuring the stable operation and efficient utilization of the power grid.

Load side: The load side includes various industrial, commercial, and residential users. Through load management and regulation technology, users can flexibly adjust their electricity consumption behavior according to actual needs, achieving energy conservation and efficient utilization.

Energy storage side: Energy storage technology is an important component of the integrated framework of source grid load storage. Through energy storage devices such as battery energy storage and compressed air energy storage, energy supply and demand can be balanced, and the flexibility and reliability of the energy system can be improved.

2.2 Solution Highlights

Energy complementarity creates the cornerstone of stable supply: We cleverly integrate wind, solar, diesel power generation, and energy storage technologies to build a powerful energy complementarity system. When the wind is strong, the wind power generation system dances in the wind, converting natural forces into electrical energy; On sunny days, the photovoltaic power generation system captures every ray of light and efficiently converts it into electrical energy. In the event of energy shortage or system failure, diesel generators will respond quickly as a solid support to ensure the continuity and stability of power supply.

Green and Clean, New Trend of Emission Reduction: We firmly adhere to renewable energy as the core, significantly reduce dependence on fossil fuels, effectively reduce carbon emissions and environmental pollution, accelerate the green transformation of energy structure, and contribute to the achievement of the dual carbon goals. At the same time, through efficient energy utilization technologies and energy storage systems, we further improve energy efficiency, maximize the value of each energy source, and reduce unnecessary waste.

Intelligent management and efficient operation in the new era: The smart energy management system, with its visual and intelligent characteristics, achieves comprehensive real-time monitoring of energy production, storage, and consumption. Through precise energy consumption analysis and intelligent prediction functions, we can gain insight into the changing trends of energy demand in advance, and adopt efficient operation strategies such as peak shaving and valley filling to optimize energy utilization and reduce operation and maintenance costs. This innovative management approach not only improves operational efficiency, but also demonstrates our profound insight into future energy management.

Flexible expansion and strong adaptability: We understand that the needs of each user are important, so we tailor energy solutions based on their actual needs and site conditions. At the same time, the system supports modular expansion. With the growth of user demand, we can easily increase power generation and energy storage capacity to ensure that energy supply is always synchronized with user demand.

Economic benefits highlighted, co creating green wealth: Through integrated energy solutions of wind, solar, diesel, and storage, users can not only achieve energy self-sufficiency, but also sell excess electricity online, thereby reducing electricity costs. In addition, the government's subsidy policies have also brought additional economic benefits to users. The efficient operation and intelligent management of the system further reduce operation and maintenance costs, improve overall economic benefits, and create more green wealth for users.

3、 Software feature interface display

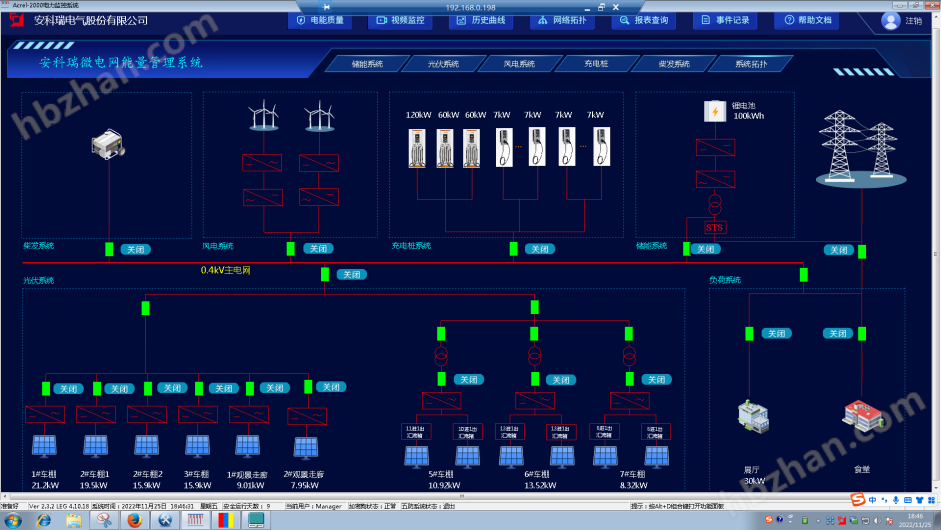

3.1 Real time monitoring

The monitoring system interface of the microgrid energy management system includes the system main interface, which includes the microgrid photovoltaic, wind power, energy storage, charging piles, and overall load composition, including revenue information, weather information, energy conservation and emission reduction information, power information, electricity quantity information, voltage and current situation, etc. According to different needs, charging, energy storage, and photovoltaic system information can also be displayed.

3.2 Photovoltaic Interface

Display information on photovoltaic systems, mainly including monitoring and alarm of the operating status of inverters on the DC and AC sides, statistics and analysis of inverter and power station power generation, monitoring and analysis of grid connected cabinet power generation, statistics of annual effective utilization hours of power station power generation, statistics of power generation revenue, carbon emission reduction statistics, monitoring of irradiance/wind power/environmental temperature and humidity, simulation and efficiency analysis of power generation; Simultaneously display the total power, voltage and current of the system, as well as the operational data of each inverter.

3.3 Energy storage interface

Display the energy storage installed capacity, current charging and discharging capacity, revenue, SOC change curve, and electricity change curve of this system. Data display and control of PCS and BMS.

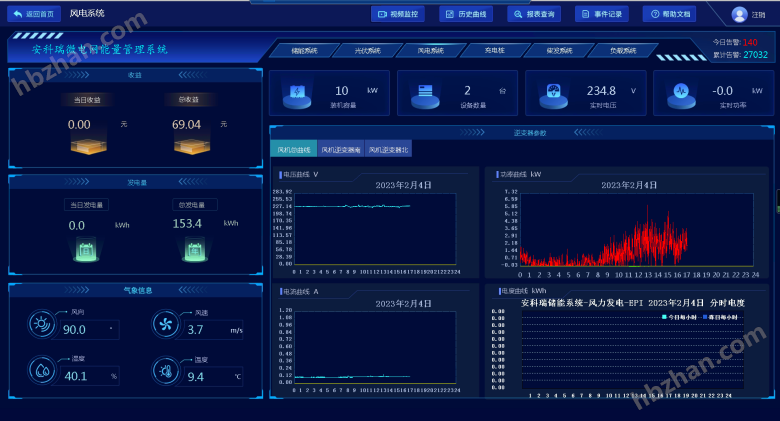

3.4 Wind Power Interface

Display information on wind power systems, mainly including monitoring and alarm of the operation status of the DC and AC sides of the inverter control integrated machine, statistics and analysis of the power generation of the inverter and the power station, statistics of the annual effective utilization hours of the power station's power generation, statistics of power generation income, carbon reduction statistics, monitoring of wind speed/wind speed/environmental temperature and humidity, simulation of power generation and efficiency analysis; Simultaneously display the total power, voltage and current of the system, as well as the operational data of each inverter.

3.5 Charging Station Interface

Display information about the charging station system, mainly including the total power consumption of charging stations, the power and electricity consumption of AC and DC charging stations, electricity costs, change curves, and operational data of each charging station.

3.6 Power generation forecast

Based on historical power generation data, measured data, and future weather forecast data, predict the short-term and ultra short term power generation of distributed power generation, and display the qualification rate and error analysis. According to power prediction, manual input or automatic generation of power generation plans can be carried out, which facilitates users to centrally control the new energy generation of the system.

3.7 Strategy Configuration

The system should be able to set the system operation mode and configure different control strategies based on power generation data, energy storage system capacity, load demand, and time of use electricity price information. Such as peak shaving and valley filling, cycle planning, demand control, anti backflow, orderly charging, dynamic expansion, etc.

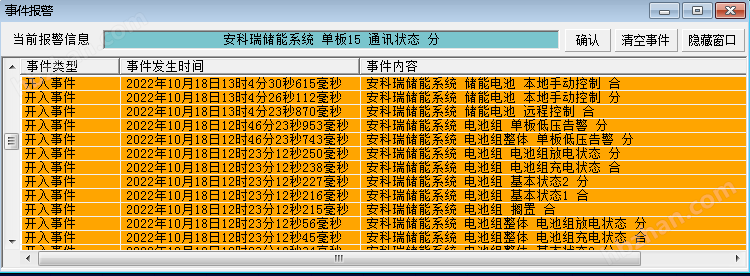

3.8 Real time alarm

Equipped with real-time alarm function, the system should be able to remotely signal the starting and closing of inverters and bidirectional converters in each subsystem, as well as issue alarms when internal protection actions or accident trips occur. It should be able to display alarm events or trip events in real time, including the name of the protection event and the time of the protection action; And it should be able to notify relevant personnel in the form of pop ups, sounds, text messages, and phone calls.

3.9 Power Quality Monitoring

Continuous monitoring of the power quality of the entire microgrid system, including steady-state and transient states, enables management personnel to grasp the power quality situation of the power supply system in real time, in order to timely detect and eliminate unstable power supply factors.

3.10 Network Topology Diagram

The system supports real-time monitoring of the communication status of various devices connected to the system, and can fully display the entire system network structure; It can diagnose the communication status of equipment online, and automatically display the faulty equipment or component and its faulty location on the interface when network abnormalities occur.

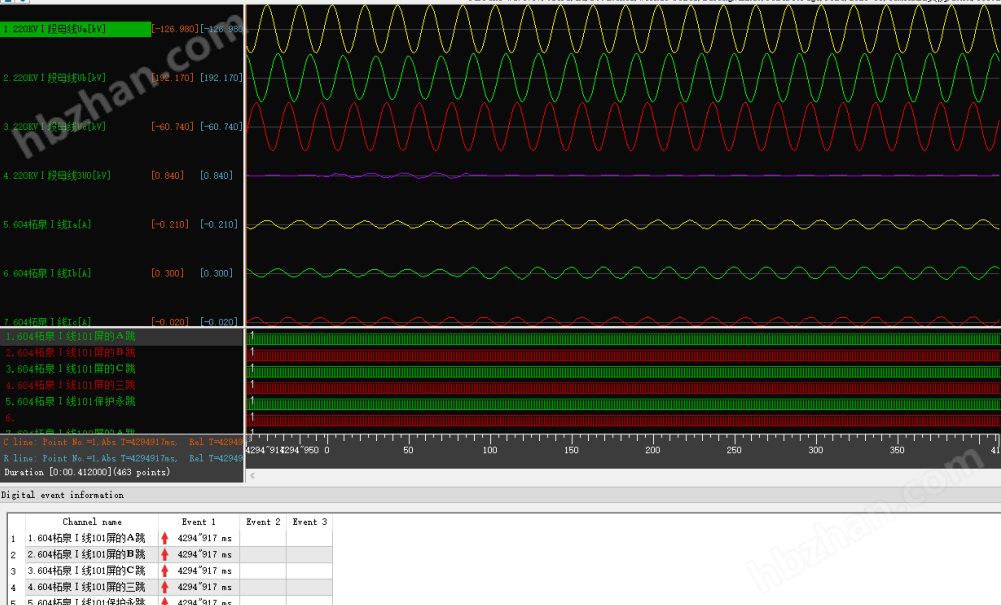

3.11 Fault recording

When the system malfunctions, it automatically and accurately records the changes in various related electrical quantities before and after the fault. By analyzing and comparing these electrical quantities, it plays an important role in analyzing and handling accidents, determining whether the protection is operating correctly, and improving the safe operation level of the power system. Among them, a total of 16 fault waveforms can be recorded, and each waveform can trigger 6 segments of waveform recording. Each waveform recording can record 8 cycles before the fault and 4 cycles after the fault, with a total recording time of 46 seconds. Each sampling point recording should include at least 12 analog waveforms and 10 switch waveforms.

3.12 Accident Remembrance

It can automatically record all real-time scanning data before and after the accident, including switch position, protection action status, remote measurement, etc., forming the data basis for accident analysis;

Users can customize the initiation event for accident recall, and store relevant point data for the 10 scan cycles before and after the accident when each event occurs. The data points for initiating events and monitoring can be freely modified by users.

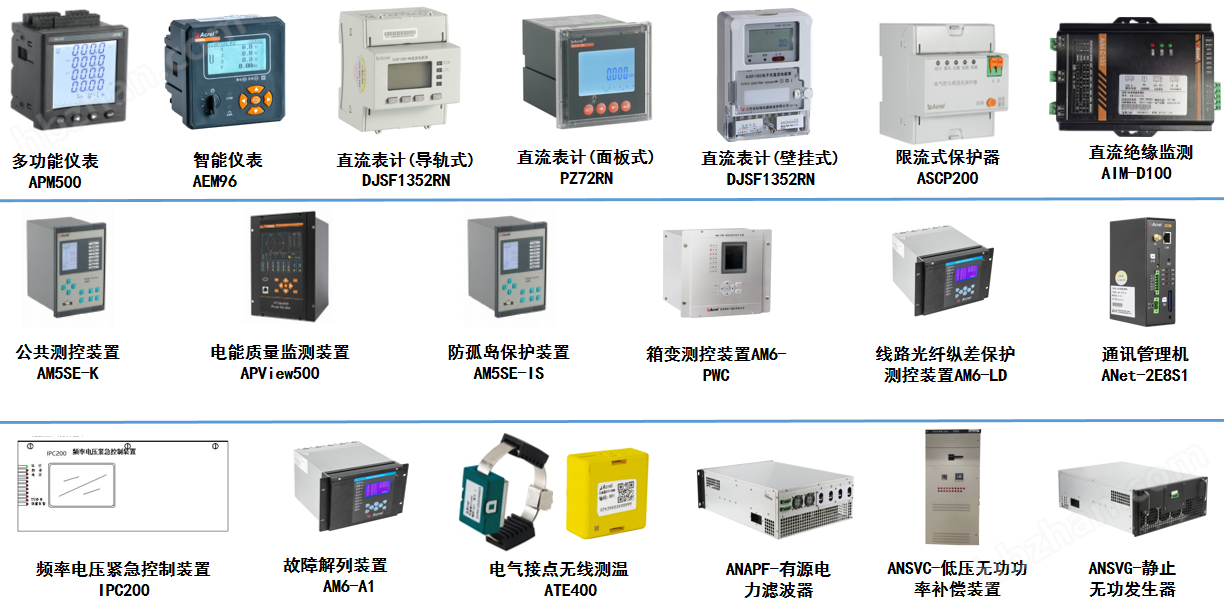

4、 Recommended hardware products

4.1 Monitoring, protection, and governance products

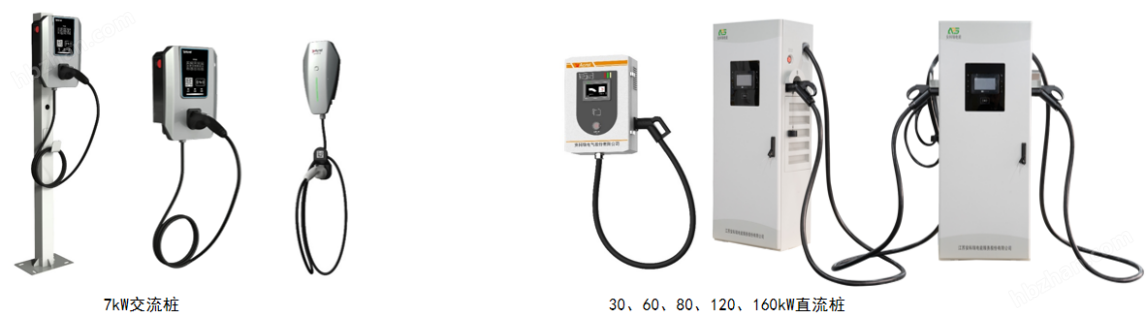

4.2 Charging Equipment - AC/DC Pile