-

E-mail

409070541@qq.com

-

Phone

18065929385

-

Address

No. 38-3 Xinhua Road, Siming District, Xiamen City

Xiamen Dace Environmental Protection Equipment Co., Ltd

Indirect heat exchange core of metallurgical high-temperature flue gas waste heat recovery device

- Model

- Nature of the Manufacturer

- Producers

- Product Category

- Place of Origin

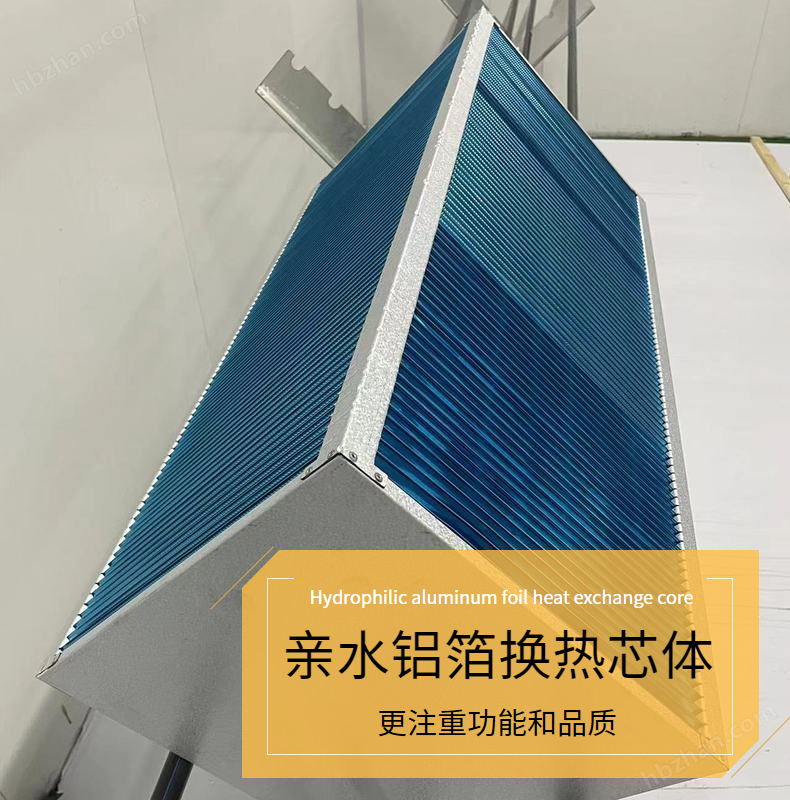

Indirect heat exchange core of metallurgical high-temperature flue gas waste heat recovery deviceIt is the core functional component of the waste gas heat recovery device, specially designed for high-temperature flue gas heat recovery scenarios in the metallurgical industry. It can accurately adapt to the flue gas treatment needs of sintering machines, electric furnaces and other equipment, and is a key supporting product for improving energy utilization efficiency.

The product uses ceramic composite materials or 316L stainless steel as the core material, which can not only withstand high temperature conditions below 800 ℃, but also resist the corrosion of acidic substances and dust in flue gas. The passivation film structure greatly improves the corrosion resistance, and the service life is extended by more than three times compared to ordinary materials.

Adopting an indirect heat exchange structure design, high-temperature flue gas is isolated from the heat exchange medium through baffles, which not only avoids cross contamination of the medium but also ensures the safety of the heat exchange process. The heat transfer coefficient can reach 30-50W/(m ² · K), and the sensible heat recovery efficiency is stable at over 75%.

The core adopts a cross flow layout to optimize the flow channel design, extending the heat exchange time between the flue gas and the medium. At the same time, the inner wall of the flow channel is treated with a special coating to reduce the risk of dust adhesion and scaling, reduce the probability of blockage, and facilitate high-pressure air blowing and cleaning in the later stage.

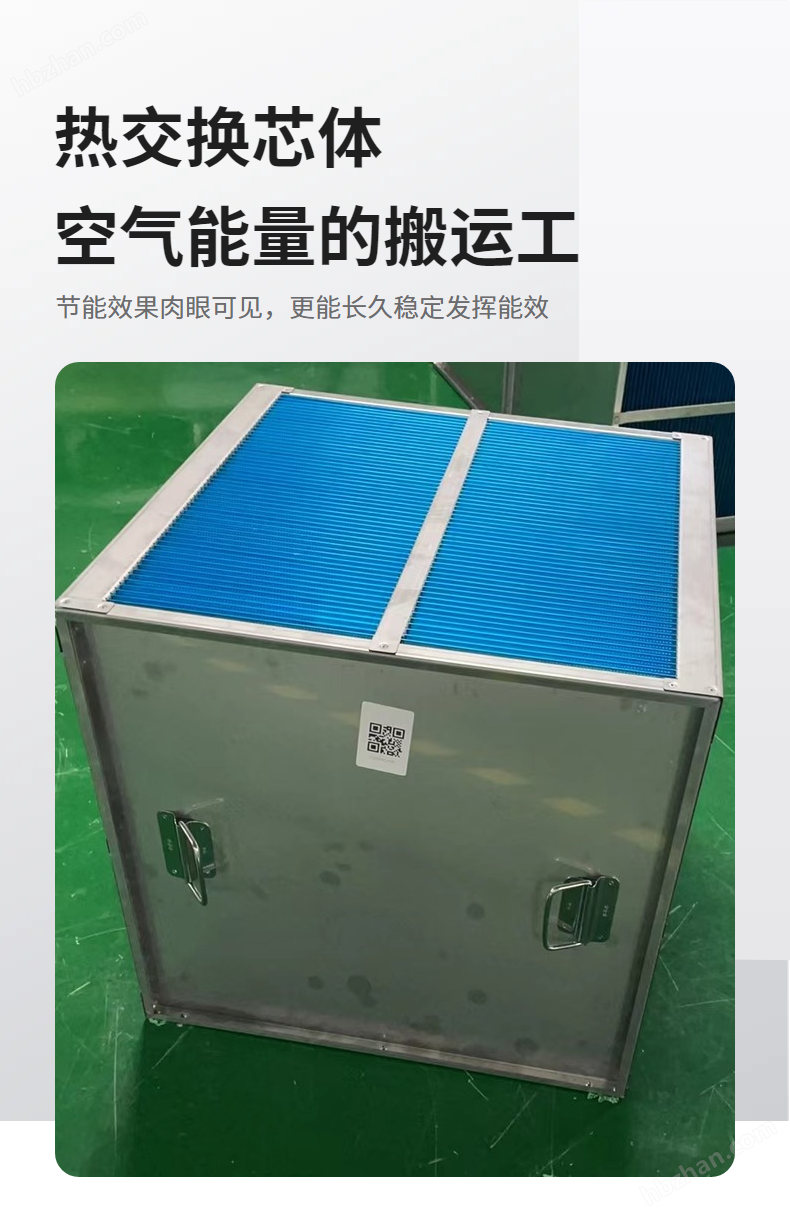

Indirect heat exchange core of metallurgical high-temperature flue gas waste heat recovery deviceSupport customized production, adjust core size and channel density according to flue gas treatment air volume and temperature parameters, and adapt to scenarios such as sintering processes in steel plants and cooling of electric furnace flue gas.

During installation, it can be directly connected to existing exhaust gas treatment systems without the need for large-scale renovation. The modular design makes single board replacement more convenient, and the cleaning cycle is extended to 12 months, reducing annual maintenance costs by 40%.

In practical applications, the flue gas temperature can be gradually reduced from 400 ℃ to below 120 ℃, and the recovered waste heat can be used for workshop heating or production preheating. Every 1MW of heat recovered can reduce CO ₂ emissions by about 0.6 tons/hour, significantly reducing enterprise energy consumption and environmental pressure, in line with industrial green development policies.