-

E-mail

409070541@qq.com

-

Phone

18065929385

-

Address

No. 38-3 Xinhua Road, Siming District, Xiamen City

Xiamen Dace Environmental Protection Equipment Co., Ltd

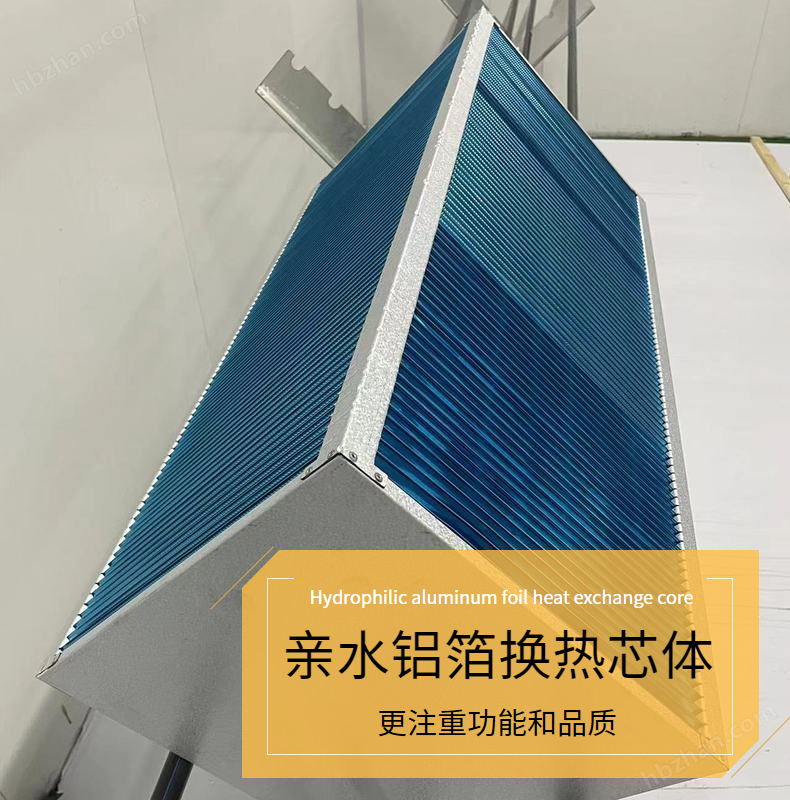

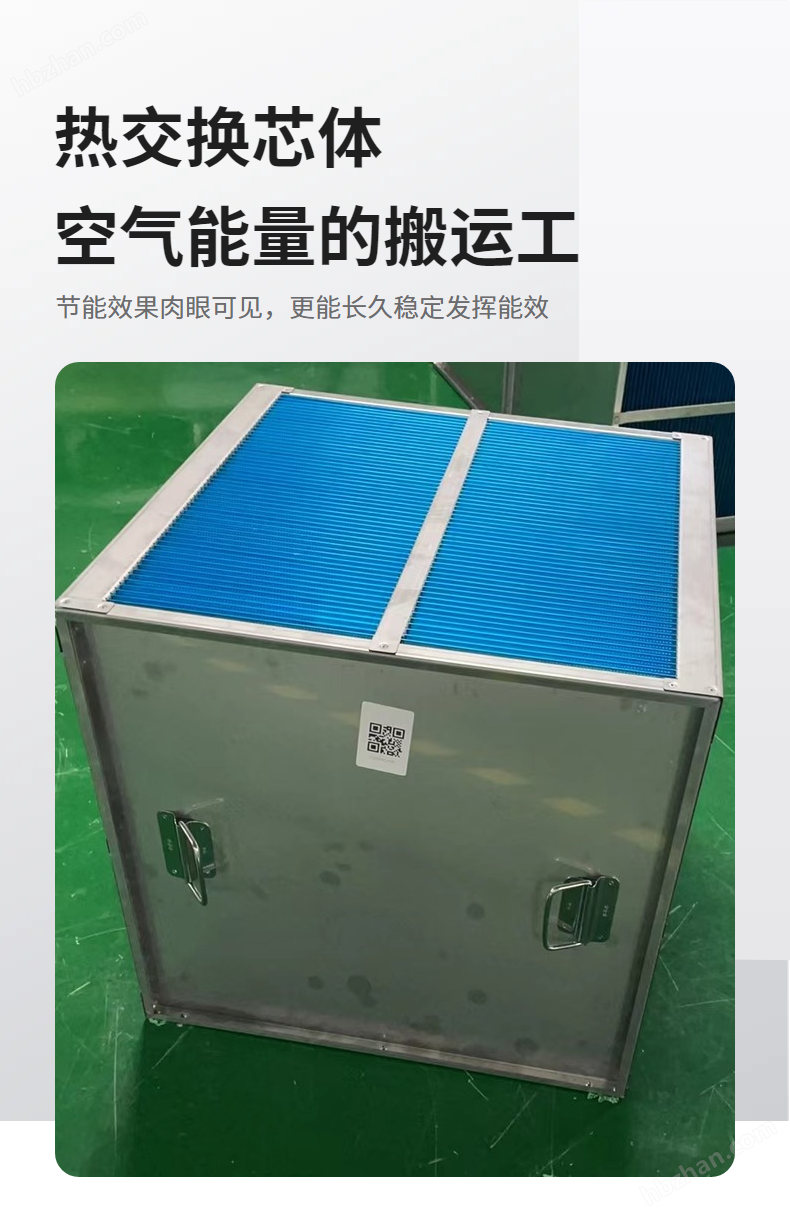

Indirect heat exchange core of waste gas heat recovery device

- Model

- Nature of the Manufacturer

- Producers

- Product Category

- Place of Origin

Indirect heat exchange core of waste gas heat recovery deviceIt is the core functional carrier of waste heat recovery equipment, designed specifically for industrial waste heat recovery in industries such as metallurgy, chemical, power, and building materials. It is a key component for realizing the resource utilization of waste heat and reducing energy consumption in enterprises.

The product is made of high-quality materials that are resistant to high temperatures and corrosion. The core material is 316L stainless steel or ceramic composite material, which can withstand the corrosion of acidic and alkaline substances in industrial waste gas. At the same time, it can adapt to high temperature conditions below 800 ℃, and its service life is extended by more than three times compared to ordinary material cores.

During the production process, multiple quality controls are implemented to ensure material purity and structural stability.

Adopting an indirect heat exchange structure design, the exhaust gas is isolated from the heat exchange medium through a partition, avoiding direct contact between the two media. This not only prevents contamination of the heat exchange medium, but also ensures the safety of exhaust gas treatment.

During the heat exchange process, the high-temperature exhaust gas transfers heat to the heat exchange medium on the other side through the baffle, with a stable heat transfer efficiency of over 75%, which can efficiently recover waste heat resources from the exhaust gas.

The internal structure of the core adopts a cross flow or counter flow flow channel layout, optimizing the flow path between the airflow and the medium, increasing the heat exchange time, and further improving the efficiency of waste heat recovery. At the same time, the inner wall of the channel is treated with a special coating to reduce the adhesion of dust and particulate matter in the exhaust gas, reduce the risk of blockage, and facilitate subsequent cleaning and maintenance.

Indirect heat exchange core of waste gas heat recovery deviceCustomized production can be carried out according to the processing air volume, exhaust gas temperature, pressure and other parameters of the waste gas heat recovery device, which is suitable for industrial waste gas treatment systems of different scales. It is widely used in scenarios such as sintering machine waste gas recovery in steel plants, reaction waste gas waste heat utilization in chemical plants, and boiler flue gas waste heat recovery in power plants.

During installation, it can be directly connected to existing waste gas and heat recovery equipment without the need for large-scale modifications to the original system. The installation cycle is short and the cost is low.

In practical applications, this indirect heat exchange core can convert the recovered waste heat into hot water, steam, or hot air, which can be used for workshop heating, production process heating, power generation, etc. It can reduce energy consumption by more than 30% on average, significantly reduce carbon emissions, help enterprises meet environmental protection and emission reduction requirements, and create considerable economic benefits for enterprises. It is a core supporting product in the industrial field that practices the concept of green development. The product has passed environmental protection and energy-saving related certifications, and its performance and quality are trustworthy.