-

E-mail

yun.zhang@evptec.com

-

Phone

19926819212

-

Address

301, Building L, No. 54-6 Guanlan Avenue, Fucheng Street, Longhua District, Shenzhen

Product Categories

Shenzhen Yiweipu Technology Co., Ltd

MVR evaporator for waste liquid treatment equipment in machining workshop

NegotiableUpdate on 01/09

- Model

- Nature of the Manufacturer

- Producers

- Product Category

- Place of Origin

Overview

This machining workshop waste liquid treatment equipment MVR evaporator is particularly versatile, capable of efficiently treating abrasive particles in grinding waste liquid, heavy metals in rust removal and phosphating waste liquid, and even viscous substances in waste lubricating oil. It does not require the addition of a bunch of chemicals, undergoes full physical treatment, and does not produce secondary pollution. The treated water quality is stable and meets the standard.

Product Details

Is it difficult to treat waste liquid in machining workshops? This device helps you achieve low emissions and save money

In the machining workshop,Cutting waste liquidOil stainsCleaning waste liquidFoamGrinding waste liquidDoes turbidity bother you every day? andRust removal and phosphating waste liquidThe acidity, alkalinity, and heavy metals inside,Waste lubricating oilThe viscosity is not only troublesome to handle, but the cost of outsourcing disposal is also increasing year by year, and there is always concern during environmental inspections.

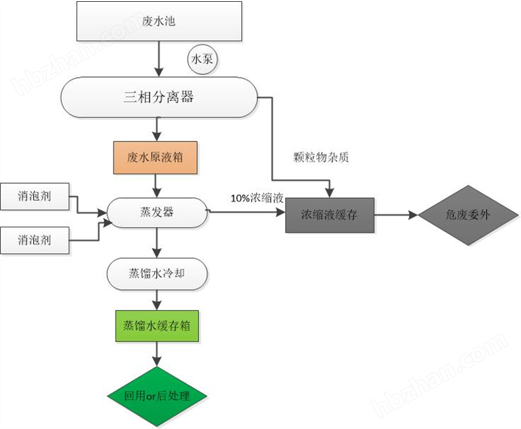

In fact, the key to treating these waste liquids is "reduction+recycling". ourMVR evaporator for waste liquid treatment equipment in machining workshopIt is specifically designed to solve this problem: it uses low-temperature vacuum evaporation technology to firstCutting waste liquid、Cleaning waste liquidThe water inside evaporates, leaving concentrated impurities that can significantly reduce the volume of waste liquid in one go. The evaporated water is very clean and can be directly reused in the cleaning process after treatment, without any waste.

this setMVR evaporator for waste liquid treatment equipment in machining workshopEspecially versatile, whether it'sGrinding waste liquidThe abrasive particles inside, orRust removal and phosphating waste liquidHeavy metals inside, evenWaste lubricating oilAll viscous substances can be efficiently processed. It does not require the addition of a bunch of chemicals, undergoes full physical treatment, and does not produce secondary pollution. The treated water quality is stable and meets the standard.

The benefits of using it are visible: the outsourcing of hazardous waste can be reduced by more than half, and the disposal costs saved in a year are particularly considerable; The evaporated water can be recycled, and the cost of new water has also decreased significantly; The equipment is designed with modularity, and can be placed in the corners of the workshop without the need for major site changes.

If you are struggling to sleep due to various waste liquids in the workshop, you may want to take a look at this set of equipment, which can transform waste liquid treatment from a "troublesome matter of burning money" to a "convenient matter of saving money", and also ensure environmental compliance.