-

E-mail

peng2022fei@qq.com

-

Phone

13069494881

-

Address

Nanzhang Industrial Zone, Wenquan Street, Wen County, Jiaozuo City, Henan Province

Jiaozuo Haofei Environmental Protection Equipment Materials Co., Ltd

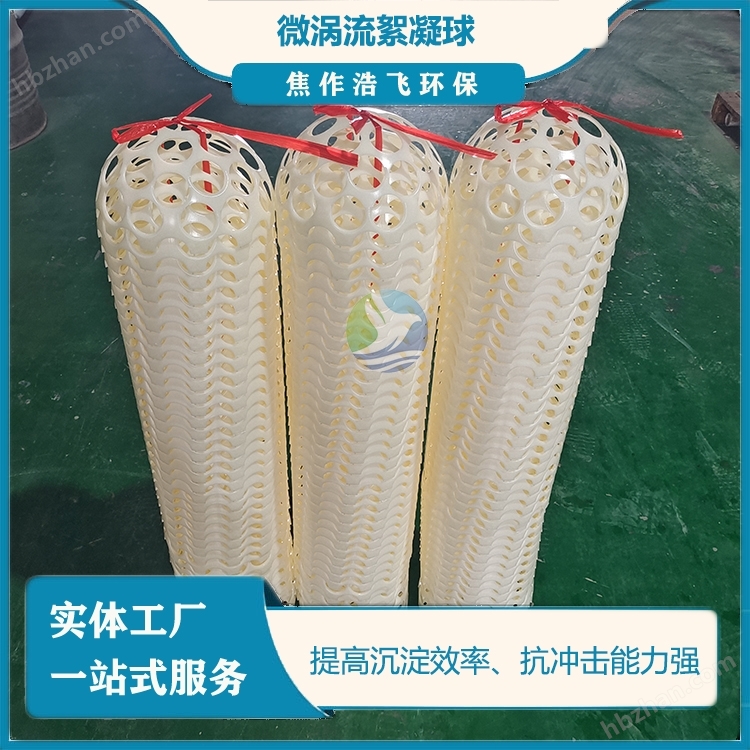

Micro eddy current flocculation reactor

- Model

- Nature of the Manufacturer

- Producers

- Product Category

- Place of Origin

Micro eddy current flocculation reactorIt is a hollow sphere used to enhance the flocculation effect during the flocculation reaction process. Its appearance is smooth, without burrs, and the interior is a hollow body with a porous diameter of 200mm on the surface. The micro vortex flocculation reaction ball is composed of two identical hemispherical shells that are interlocked by claws and reinforcing ribs at the edges of their larger tangential surfaces. A hemispherical shell is composed of interconnected longitudinal and latitudinal bars, which enclose through holes to provide water flow channels.

The technical parameters of ABS flocculation balls include a diameter of 200mm, a ball content of 135 per cubic meter, a surface opening diameter greater than 30, and an opening rate greater than 60%. In addition, the flocculation time is 5-8 minutes, the empty bed flow rate is 60-360m/h, and the head loss is 0.01-0.02m/m.

Micro eddy current flocculation reactorThe reaction principle is achieved through micro eddy current reaction and contact flocculation for flocculation. When the water flows through a large number of holes on the wall of the micro vortex flocculation device, countless small vortices will be formed. According to modern coagulation theory, micro eddies facilitate the migration and collision condensation of small particles in water, thereby improving reaction efficiency. In addition, due to the hollow shell of the micro vortex flocculation device and the low internal flow velocity, a large number of larger particle size flocs (alum flowers) accumulate and suspend in the water. These suspended flocs can adsorb small flocs, that is, contact flocculation. The micro vortex flocculation device also has the functions of preventing water flow short circuit, evenly distributing water flow, and increasing flow velocity gradient.

ABS flocculation ballHas the following characteristics:

Efficient flocculation effect: The flocculation reaction time can be shortened to 8 minutes.

Improving effluent quality: Due to the three-dimensional contact flocculation effect inside the micro vortex flocculation device, the quality of flocs (alum flowers) is improved and the sedimentation efficiency is increased.

Strong impact resistance: The large amount of active flocs accumulated inside the micro vortex flocculation device has a buffering effect, allowing the system to withstand large impact loads.

Simple construction: The micro vortex coagulation reaction ball can be directly installed and used without complex installation steps.