-

E-mail

yy-valve@163.com

-

Phone

13801619288

-

Address

No. 18, Zhuangxing Industrial Park, Fengxian, Shanghai

Yuanyi Valve Co., Ltd

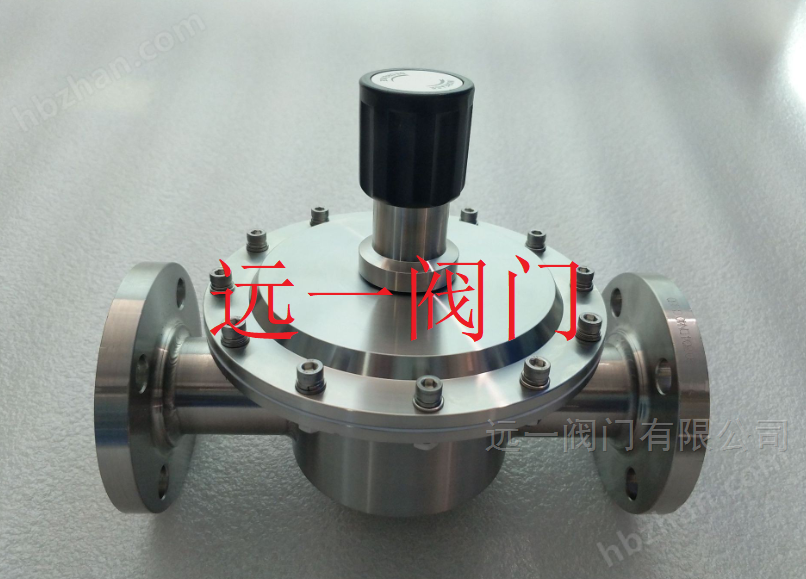

Micro pressure back pressure valve

- Model

- Nature of the Manufacturer

- Producers

- Product Category

- Place of Origin

Micro pressure back pressure valveIntroduction:

Back pressure valve can stabilize pipeline pressure, provide a stable back pressure for the system, and improve material feeding accuracy; It can also be used as a nitrogen sealing valve for storage tanks or as a pressure relief valve for storage tanks!

Working Principle:

The rated pressure of the back pressure valve can be adjusted, usually by adjusting the top rod of the spring to adjust the length of the spring. The fluid enters from the back pressure valve inlet and is blocked by the diaphragm, causing the fluid to exert upward pressure on the diaphragm. When the pressure is high enough, the spring is compressed, and the fluid pushes up the diaphragm to form a channel, which flows out from the outlet of the back pressure valve; If the fluid pressure is not sufficient, it will form a build-up pressure, causing the inlet pressure to rise until it reaches the rated pressure, and lifting the diaphragm to form a passage.

Product Features:

material

Valve body, valve core, spring seat... SS304 or 316L stainless steel

Spring...... 65Mn (customizable stainless steel)

Valve seat O-ring... Fluororubber

Diaphragm... PTFE, NBR, Fluororubber (can be customized according to requirements)

(1) Pressure sensing form... diaphragm type

(2) Pressure gauge interface... 1/4 "NPT internal thread

(3) Interface size... 1/8 "-1" internal thread, flange, sleeve, quick fit, etc., can be customized according to requirements

(4) Working temperature: -20-140 ℃

(5) Enduring pressure up to a maximum of 6 bar

(6) Pressure regulation range: 0-30KPa; 0-50KPa; 0-100KPa

high trafficMicro pressure back pressure valveProduct features

(1) All stainless steel valve body, PTFE diaphragm, optional EPDM or kalrez material O-ring and valve seat. The product can be used in industries such as food, pharmaceuticals, and chemicals.

(2) Balanced valve seat, external pressure feedback, ultra large diaphragm sensing, extremely precise and stable pressure control. Adjustable pressure to zero.

(3) Internally designed for easy cleaning and capable of online CIP cleaning. Easy maintenance, no need to remove the back pressure valve for online repair and replacement of parts.