-

E-mail

liuyanhe@zhderx.com

-

Phone

13005602816

-

Address

Zhuhai New Olin Technology Park

- Acetone wastewater low-temperature evaporation treatment equipment

- Sodium sulfate mixed salt solution dryer

- Polyethylene glycol wastewater concentration equipment

- Dimethyl sulfoxide wastewater treatment equipment

- Organic solvent wastewater concentration treatment equipment

- Wastewater phosphoric acid recovery equipment

- Mother liquor drying machine

- Electroplating wastewater evaporation crystallization equipment

Zhuhai Derunxin General Machinery Co., Ltd

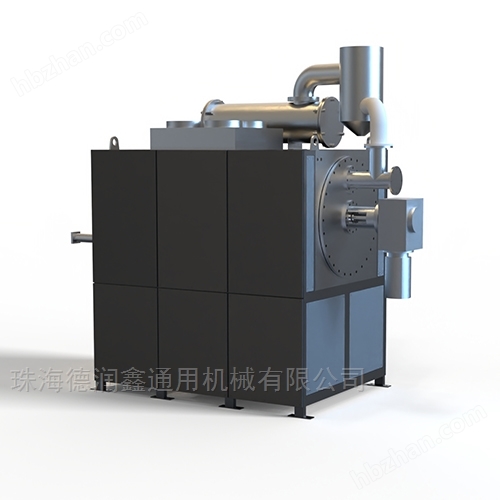

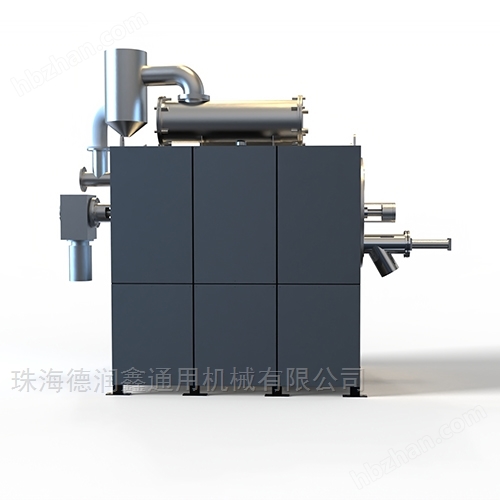

Mother liquor drying machine

- Model

- Nature of the Manufacturer

- Producers

- Product Category

- Place of Origin

(1) Working principle:

Mother liquor drying machineMaintain the vacuum degree of the evaporation chamber at -95~-97kPa through a vacuum pump, reducing the boiling point of the mother liquor to below 40 ℃. The heating system (steam/thermal oil) transfers heat to the mother liquor, promoting rapid vaporization of water and avoiding material denaturation or coking caused by high temperature. The built-in spiral scraper continuously stirs at a speed of 0.5-2 rpm, synchronously achieving three major functions: preventing high viscosity concentrated liquid from adhering to the heat exchange surface, ensuring a stable heat transfer efficiency of over 85%; Crushing crystalline particles to promote uniform growth; The mixing shaft is equipped with a built-in heating module, which enhances the deep crystallization effect and increases the discharge dryness by 20%. The PLC system monitors the liquid level, temperature, and vacuum degree in real time, automatically adjusts the feeding speed, scraper frequency, and crystal discharge cycle, and achieves unmanned operation throughout the entire process.

(2) Equipment advantages:

Low temperature protection and efficient drying

Avoid the decomposition of thermosensitive materials (such as antibiotics and lithium battery electrolytes) under low temperature conditions of 35-45 ℃ to ensure the activity of the components;

The drying efficiency of the mother liquor reaches 80% -90%, the evaporation intensity is ≥ 15kg/(m ² · h), and the processing capacity covers 3-200 tons/day.

Anti scaling and long-term operation

Scraper stirring and forced circulation technology extend the continuous operation cycle of the equipment to over 18 months, reducing maintenance frequency by 70%;

Made of 2205 duplex stainless steel or Hastelloy alloy material, resistant to strong acid and alkali corrosion, with a service life of over 10 years.

Resource utilization and cost optimization

Crystalline salt with a purity of ≥ 98% can be resold as industrial raw materials (such as nickel plating salts and pharmaceutical grade sulfates) to achieve hazardous waste reduction and increase revenue;

The operating cost per ton of water is as low as 18 yuan (12 yuan for electricity, 3 yuan for chemicals, and 3 yuan for maintenance), saving more than 60% of costs compared to outsourcing disposal.

Intelligence and Convenience

Skid mounted modular design reduces footprint by 50%, and installation and debugging can be completed within 72 hours;

Integrated IoT data platform, supporting remote monitoring, fault self diagnosis, and AI predictive maintenance.

(3) Equipment case

Case 1: Drying project of high salt mother liquor in coal chemical industry

Project Background

A certain coal tar processing enterprise produces 30 tons of crude phenol high salt mother liquor (with a salt content of 15000mg/L and COD of 25000mg/L) daily. The original vacuum drum drying equipment was clogged due to scaling, and the processing capacity only reached 30% of the design value, and the moisture content of the dry slag was greater than 30%.

Solution

Adopting a daily processing capacity of 15 tonsMother liquor drying machineConfigure a spiral scraper mixing and steam spiral filtration system;

Vacuum degree -96kPa, evaporation temperature 42 ℃, steam consumption 1.2 tons/ton of water;

Dry slag is directly bagged by a screw conveyor, with a stable moisture content of 8% -10%.

processing effect

Reduction: The volume of mother liquor has been reduced from 30 tons/day to 6 tons/day, saving 2.4 million yuan in hazardous waste disposal costs annually;

Water quality improvement: The COD of condensate water has been reduced from 25000mg/L to 45mg/L and reused in production processes;

Case 2: Biopharmaceutical Mother Liquor Resource Utilization Project

Project Background

A certain antibiotic production enterprise produces 10 tons of fermentation mother liquor per day (with a salt content of 8000mg/L and COD of 18000mg/L), which contains cephalosporin drug intermediates. The original multi effect evaporation process resulted in a loss rate of over 30% of active ingredients.

Solution

Customized low-temperature drying system with a vacuum degree of 97kPa and a temperature of 38 ℃, equipped with an online mass spectrometry analysis module;

Adopting a dual axis reverse rotating scraper to strengthen shearing and prevent the agglomeration of viscous materials;

Steam is recovered through MVR technology, reducing the water consumption per ton to 65kWh.

processing effect

Ingredient retention: The effective ingredient recovery rate reaches 95%, and the dry residue can be directly reused as pharmaceutical raw materials;

Implementation: When the TDS of condensed water is less than 100mg/L, 100% of it is reused in the fermentation section;