-

E-mail

m13404111885@163.com

-

Phone

13404111885

-

Address

Jinniu Lake Economic Development Zone, Liuhe District, Nanjing

Nanjing Jiangjin Environmental Protection Equipment Co., Ltd

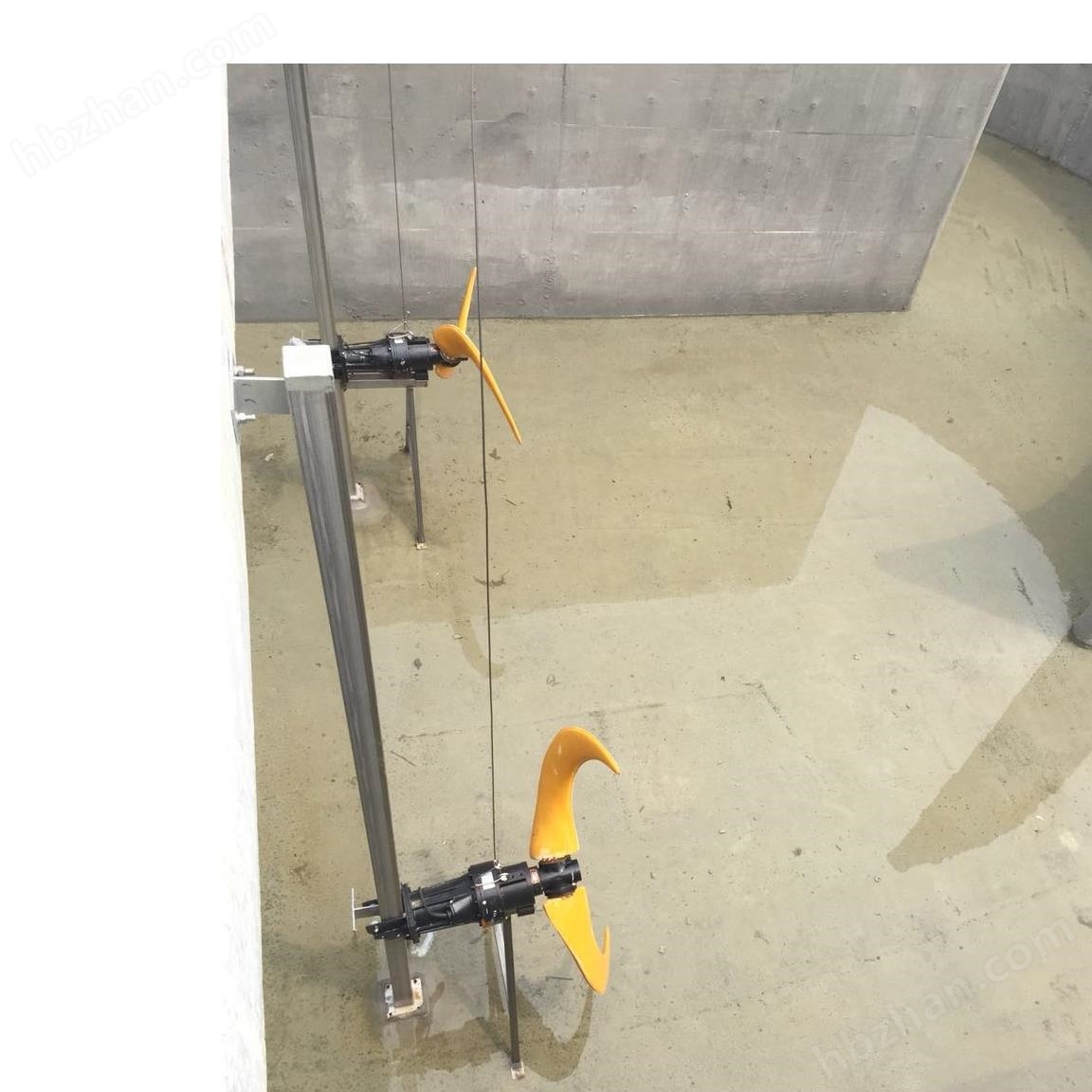

On site installation diagram of low-speed submersible thruster for first level aerobic tank

- Model

- Nature of the Manufacturer

- Producers

- Product Category

- Place of Origin

On site installation diagram of low-speed submersible thruster for first level aerobic tank

Nanjing Jiangjin Environmental Protection Equipment

The low-speed thruster of the hydrolysis and biochemical system can be lifted and lowered, and can be easily removed for inspection or service without the need for personnel to enter the pool or well. divingThrusterAfter installation, there should be a sliding guide bracket as an integral part of it. divingThrusterThe entire weight should be stressed on a bracket that can withstand divingThrusterAll the thrust caused. divingThrusterIts accessories and cables can be continuously submerged at a depth of20Under water without losing its water tightness.

1: Design of submersible thruster

1、diving push flowThe device is capable of treating raw water and wastewater that has passed through a grid. The mixer can be raised and lowered, making it easy to move and inspect or repair without the need for personnel to enter the wet well. The mixer is installed through a square or rectangular guide rod system The mixer, accessories, and cables can be used20Continuous diving operation at a depth of meters without leakage. The main castings of the mixer, except for the base and blades, are gray cast iron,ASTM A-48 Class 35B, orEN1561-GJL250The surface is smooth, without bubbles or other irregularities. All cast iron surfaces that come into contact with the stirring liquid outside the mixer are coated with a spray coating for protection. All nuts, screws, and washers areAISI316Stainless steel or better material.

2、Motors and Drivers

The submersible thruster motor is a submersible full copper coilThe motor is integrated with a speed control driver and installed in an inflatable waterproof casing. The motor efficiency should be equivalent toIE4The speed of the mixer can be adjusted through remote communication or a separate control panel. The driver can monitor temperature and current, and stop the operation of the mixer in case of overload. The stator winding and stator wire are insulated to resist moisture, with an insulation level ofHlevel180°CAt that time. The stator is insulated by drip method and embedded in a cast iron stator chamber. There is no upper limit to the number of starts per hour for the motor.

3、gearbox

The gearbox is a two-stage, helical gearbox equipped with high-precision, low load gears. The motor shaft is equipped with an integrated transmission gear. The intermediate shaft rotates in two spherical roller bearings and contains a secondary transmission gear. The impeller shaft contains a two-stage transmission gear and rotates in a single row and a double row angular contact ball or roller bearing.

4、Cable entrance

The cable entry seal includes a cylindrical elastic liner and does not use epoxy, silicone, or other secondary sealing systems for sealing.

5、bearing

The submersible thruster motor shaft rotates on two lubricated bearings. The inner bearing is a single row deep groove ball bearing, and the main bearing is a spherical roller bearing.

6、mechanical seal

Each thruster has an oil chamber for the shaft sealing system and an independent second oil chamber for the gearbox. The oil drain and inspection plug are easy to access from the outside. Each mixer is equipped with a three seal to separate the various parts of the mixer. The outer seal on the impeller shaft is a mechanical seal consisting of a corrosion-resistant sintered tungsten carbide ring that is stationary and rotates in the forward direction. Sealed in an oil chamber that lubricates overlapping sealing surfaces at a constant speed through hydraulic action. Only the sealing surface of the outer seal can be exposed to the stirring liquid.

The internal seal on the impeller shaft is a nitrile rubber lip seal, which can isolate the impeller shaft oil chamber from the gearbox oil chamber. The third seal is a fluororubber lip seal installed on the motor shaft, which can isolate the gearbox oil chamber from the stator chamber. The seal should not require maintenance or adjustment.

7、oil

Oil chamber injection meets the requirementsFDA172.878Sanitary standard white paraffin lubricating oil, free of aromatic hydrocarbons and according toFDA172.878Handling of hygiene standards. The model should be injected into the gearbox100numberGearbox oil.

8、Leaf wheel shaft

The material of the impeller shaft is stainless steelASTM/AISI 431orEN10088-3-1.4057Or other equivalent materials.

9、impeller

The submersible impeller consists of fiberglass reinforced polyurethane blades, each with a stainless steel shaft installed in a cast iron wheel hub. Each blade is installed in a socket on the side of the hub. The propeller shaft is axially fixed to the hub by bolts.

The blade shape is an unobstructed, swept back design, starting from the wheel, so no part of the shaft is exposed.

2: Product testing

According to the customer's needs, based onISO 21630:2007Standard, conduct thrust and power tests on the mixer.The submersible thruster Du'an Environmental Protection conducts the following inspections and tests before the equipment leaves the factory:

Motor insulation testing, testing motor insulation defects.

Conduct airtightness experiments on the assembled impeller using vacuum method.

Dry running test to confirm mechanical integrity and correct rotation direction.

According to customer requirements, provide a written report before the submersible thruster leaves the factory, indicating that the mixer has passed the above tests.

On site installation diagram of low-speed submersible thruster for first level aerobic tank

anti-corrosionInstructions:

Diving propellerThe material is suitable for the corrosive environment of sewage treatment plants. For unprotected or non anti-corrosion materials, rust removal treatment and anti rust paint coating should be carried out according to industry standards.

Outside the submersible thrusterinspection:

1. After installation guidance, inspection shall be carried out according to technical requirements, and the allowable deviation shall meet the specified indicators.

2. Check and add lubricating grease.

3. Under the designed load conditions, the submersible thruster operates smoothly with no jamming or shaking.

4. Conduct on-site load testing, operate with load for 24 hours under design conditions, measure unit volumetric power and verify flow rate.

Product Features:

1.Submersible thrusters have compact structure, small volume, and light weight. The characteristics of simple operation and maintenance, convenient and fast installation, and long service life.

2.The blades have self-cleaning function, which can prevent the entanglement and blockage of debris.

3.When used in conjunction with an aeration system, energy consumption can be significantly reduced, oxygen filling can be significantly increased, and sedimentation can be effectively prevented.

4.The motor winding isFGrade insulation, protection level isIP68Choose a maintenance free imported bearing with one-time lubrication, which has oil chamber leakage detection and motor winding overheating protection functions, making the operation of the motor safer and more reliable.

5.The friction material of the mechanical seal is corrosion-resistant tungsten carbide, and all fasteners are made of stainless steel.