-

E-mail

395752067@qq.com

-

Phone

18189108361

-

Address

Room 403, Building 3, Zhongxing Deep Blue Technology Industrial Park, Fengdong New City, Xi'an City, Shaanxi Province

Xi'an Runlai Instrument Co., Ltd

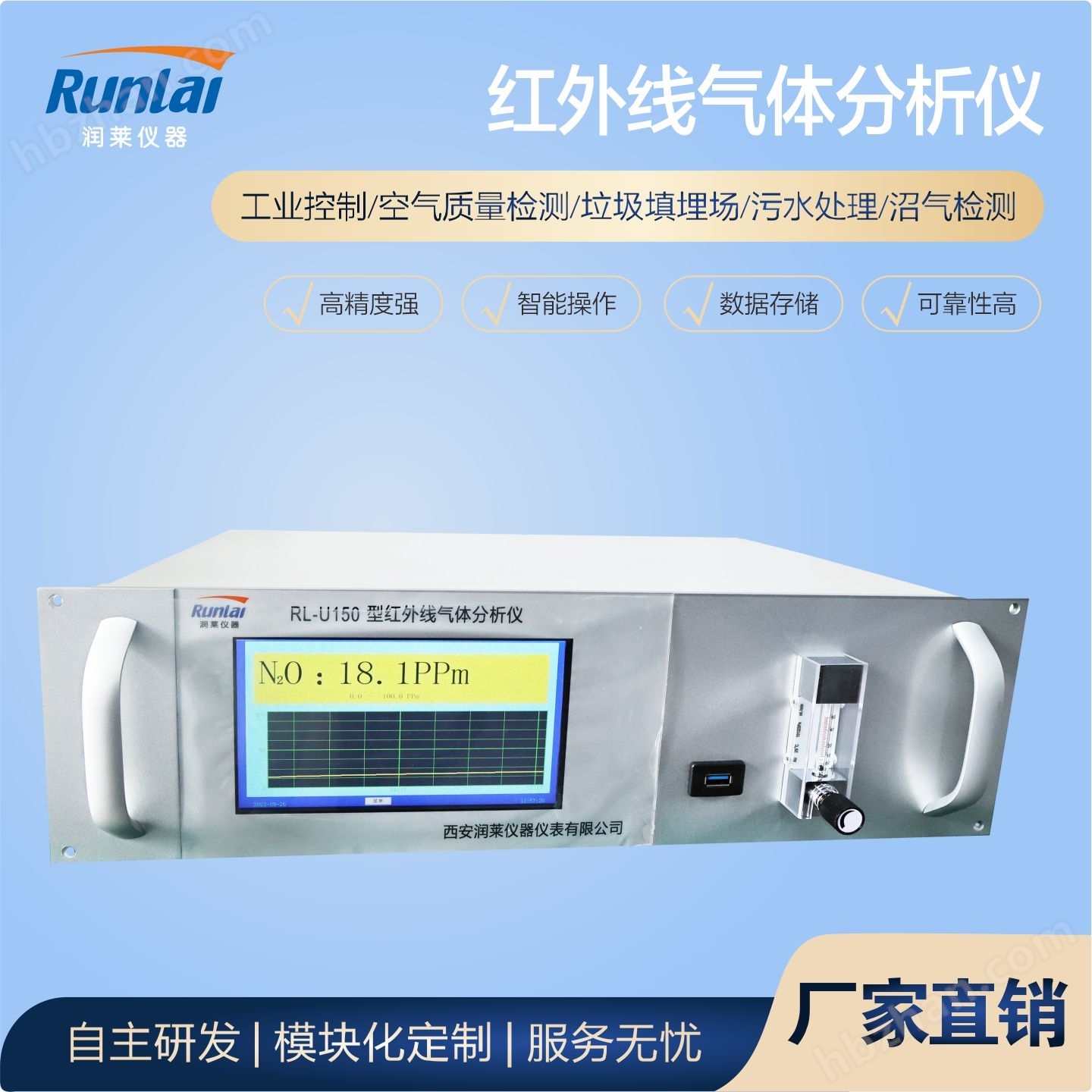

Online infrared gas analyzer

- Model

- Nature of the Manufacturer

- Producers

- Product Category

- Place of Origin

Instrument Overview:

Online infrared gas analyzerIt is a new intelligent online gas analyzer developed by our company using imported high-performance sensors combined with high-precision production processes and new microcomputer technology. The analyzer is based on the principle of infrared sensors and has the characteristics of high measurement accuracy, high performance stability, fast response time, wide applicability, and long service life. All indicators meet or exceed similar products at home and abroad.

Basic product parameters:

Measurement principle: Non dispersive infrared (NDIR)

Measurement range: 0-100% (range can be freely selected)

Accuracy: ≤± 2% F.S

Resolution: 0.01%

Repeatability: ≤± 1% F.S

Stability: Zero drift ≤± 1% F.S/7d

Range drift ≤± 1% F.S/7d

Response time: τ 90 ≤ 15S

Storage interval: 1S-99min (can be set arbitrarily)

Storage points: millions of records+

Instrument lifespan: 6 years for the entire machine (under correct operating conditions)

Electrical parameters:

Working voltage: 220-240VAC, 50 \ \ 60Hz

Whole machine power consumption: ≤ 15W

Digital signal: Standard RS485/RS232 communication port, capable of bidirectional communication with computers

Analog output: 4-20mA standard output signal, load resistance less than 500 ohms (0-10V optional)

Structural parameters:

Installation method: Embedded installation

Dimensions: 482mm (width) × 136mm (height) × 370mm (depth)

Hole size: 440mm (width) × 136mm (height)

Import and export: Φ 6 card sleeve interface (customizable)

Whole machine weight: approximately 8Kg

Environmental parameters:

Environmental temperature: -25 ℃ to+55 ℃

Environmental humidity: ≤ 90% RH

Inlet pressure: 0.05 MPa ≤ Inlet pressure ≤ 0.25 MPa

Sample gas flow rate: (400 ± 50) mL/min

Sample gas requirements: dust-free, anhydrous, oil-free

Instrument features:

The configuration, calibration, and testing of various instrument parameters can be carried out in the form of a fully Chinese touchable menu. Historical records and curves can be quickly operated according to time settings;

● It can display measurement values, historical curves, ranges, statuses, and various parameter settings interfaces simultaneously;

Imported sensors are selected, which have the characteristics of long lifespan, high accuracy, and fast response;

When there is no one on duty, the timed automatic storage function allows for viewing of stored data at any time;

● Built in temperature compensation to reduce the impact of sample gas temperature and environmental changes on measurement accuracy;

64M memory, 128M FLASH USB interface for convenient customer data storage;

Ethernet port enables connection to the wide area network;

Adopting a new type of air flow stabilization system; It has the advantages of technology, high precision, fast response, stable performance, complete functions, easy operation, and continuous gas analysis process;

● Built in vacuum pump (optional)

Application fields:

Online infrared gas analyzerWidely used in the air industry, industrial control, industrial flue gas emission monitoring, gas detection in petrochemical processes, air quality detection, biogas content detection in landfills, sewage treatment plants, biogas engineering, and infrared detection in industrial fluid welding processes.

Dimensional drawing: