-

E-mail

liuyanhe@zhderx.com

-

Phone

13005602816

-

Address

Zhuhai New Olin Technology Park

- Acetone wastewater low-temperature evaporation treatment equipment

- Sodium sulfate mixed salt solution dryer

- Polyethylene glycol wastewater concentration equipment

- Dimethyl sulfoxide wastewater treatment equipment

- Organic solvent wastewater concentration treatment equipment

- Wastewater phosphoric acid recovery equipment

- Mother liquor drying machine

- Electroplating wastewater evaporation crystallization equipment

Zhuhai Derunxin General Machinery Co., Ltd

Phosphoric acid wastewater recovery crystallization equipment

- Model

- Nature of the Manufacturer

- Producers

- Product Category

- Place of Origin

1、 Working principle

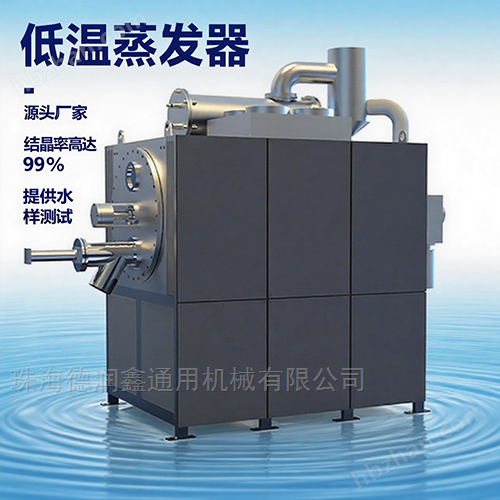

Phosphoric acid wastewater recovery crystallization equipment:By combining low-temperature heat pump technology with vacuum evaporation system operation, phosphoric acid wastewater is first heat exchanged with condensed water through a preheater to recover energy, and then enters the vacuum evaporation chamber. Under the low-temperature heat source provided by the heat pump at 40-70 ℃, it rapidly evaporates to produce secondary steam; The secondary steam is condensed into reusable or dischargeable condensate through a condenser, while the concentration of wastewater increases to supersaturation after continuous evaporation of water. It enters the crystallizer and undergoes stirring and temperature control to crystallize and precipitate solutes. Finally, it is separated into recyclable crystalline salts through solid-liquid separation equipment.

2、 Equipment features

Low temperature operation, energy-saving and efficient:Phosphoric acid wastewater recovery crystallization equipmentBy adopting heat pump technology, the evaporation temperature is low, reducing thermal energy loss, and saving more than 50% energy compared to traditional high-temperature evaporation equipment, significantly reducing operating costs.

Efficient crystallization and resource recovery:Accurate control of crystallization conditions, high crystallization efficiency, high purity of precipitated crystal salts, can achieve resource recovery, and create additional economic benefits.

Corrosion resistant design, durable and long-lastingThe components in contact with wastewater are made of corrosion-resistant materials such as titanium alloy and PPH, which can withstand the strong corrosiveness of phosphoric acid wastewater and extend the service life of the equipment.

Fully automated control, easy to operateEquipped with a PLC control system, it can achieve automated operation of the entire process of feeding, evaporation, crystallization, separation, etc., reducing manual intervention, lowering operational difficulty, and ensuring stable operation of the equipment.

Environmental compliance standards:The treated condensate water has excellent quality and meets the standards for reuse or discharge; After proper treatment of crystalline salt, there is no secondary pollution and it meets environmental protection requirements.

Modular design, flexible adaptation:The equipment adopts a modular structure, which can be flexibly combined according to the wastewater treatment capacity (5-500 m ³/d), occupies a small area, is easy to install and debug, and is convenient for later expansion or renovation.

Classic Case

Chemical Enterprise Phosphoric Acid Wastewater Treatment Project: The enterprise generates 80m ³ of phosphoric acid wastewater per day, with a phosphate concentration of about 5000mg/L and a fluoride ion concentration of 800mg/L. After using this low-temperature evaporation crystallization equipment, the concentration of phosphate ions in the treated condensate water is reduced to below 5mg/L, and the concentration of fluoride ions is below 10mg/L, meeting the reuse standard. About 1.2 tons of crystalline salt are recovered daily, which can be purified and reused as industrial raw materials, saving about 800000 yuan in water and raw material costs annually.

A certain pharmaceutical factory's phosphoric acid wastewater treatment project: In response to the high concentration phosphoric acid wastewater (COD about 3000mg/L, phosphate ions 8000mg/L) of the factory, the equipment has achieved over 95% water evaporation, with a crystal salt purity of over 90%. The treated distilled water meets the requirements ofThe emission standards have solved the long-term environmental problems of enterprises and passed the acceptance of the environmental protection department.