-

E-mail

970805072@qq.com

-

Phone

15838053733

-

Address

No. 99, Jingsan Road North, Jinshui District, Zhengzhou City

Zhengzhou Jiutai Technology Co., Ltd

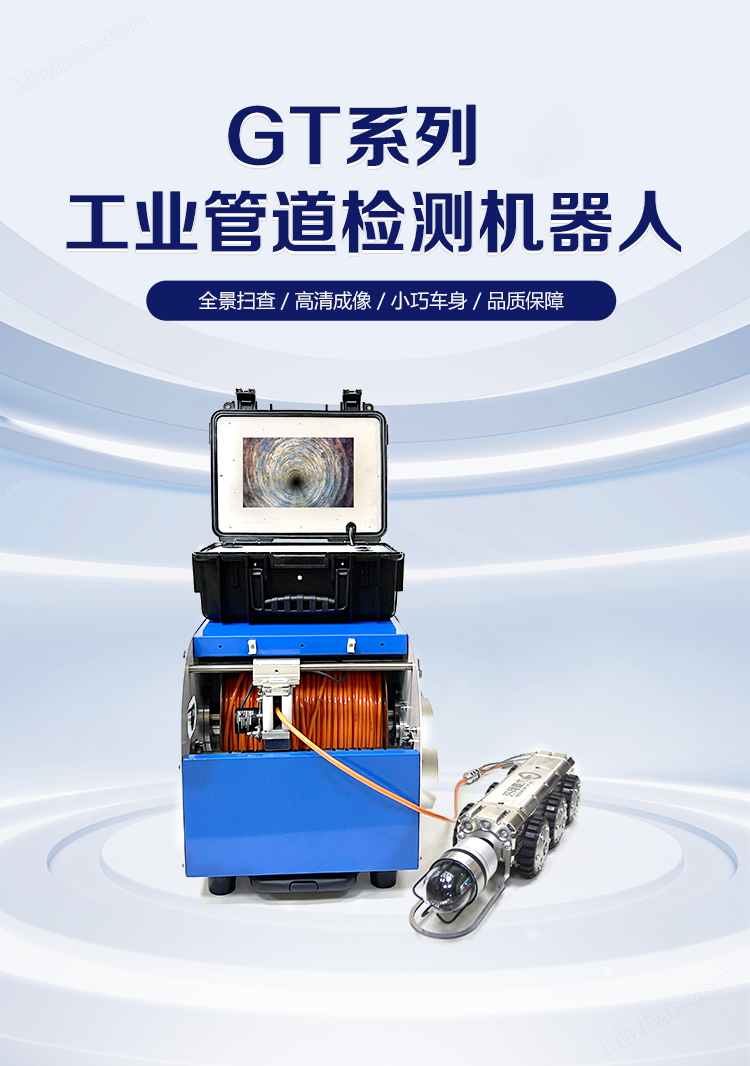

Pipeline endoscopic robot

- Model

- Nature of the Manufacturer

- Producers

- Product Category

- Place of Origin

HB-GTR120 seriesPipeline endoscopic robotIt is an intelligent device designed specifically for internal pipeline inspection, which embodies the deep pipeline intelligent inspection technology accumulation of Jiutai Technology for 15 years.Robots have efficient exploration capabilities,Covering the quality of weld formation and identification of small defects, assessment of corrosion areas on pipe walls and their severity, as well as investigation of abnormal conditions such as structural damage, deformation, and foreign object blockage. By utilizing high-definition camera units and real-time image transmission technology, the internal images of the pipeline are synchronously transmitted back to the ground control terminal, achieving visual monitoring and data recording of the pipeline's health status. Based on clear image feedback, operators can quickly locate weld hazards, accurately identify corrosion concentration areas and other potential leakage risk points, thereby significantly improving the efficiency, accuracy, and operational safety of pipeline inspection work, providing reliable data support and decision-making basis for pipeline operation and maintenance management.

Pipeline endoscopic robotCore advantages and breakthrough pain points:

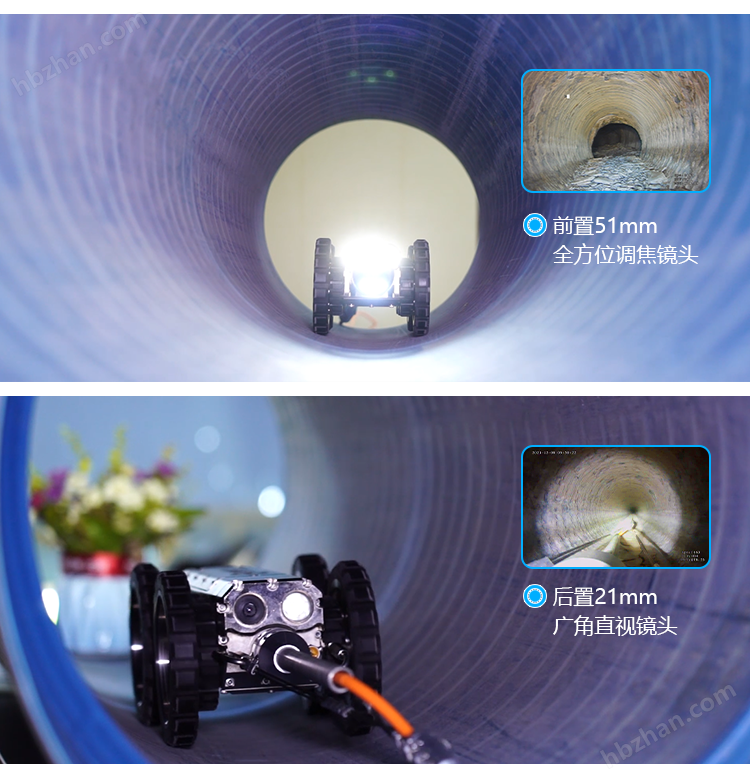

▶ 2 million pixel ultra clear field of view: equipped with an industrial grade high-definition camera system, it can transmit real-time and detailed images of the inner wall of the pipeline. Whether it's small cracks or corrosion marks, the details are under control, bidding farewell to the era of vague misjudgment.

▶ Panoramic agilityprobeAxial 360 ° infinite rotation+radial 220 ° large angle flipping, free switching of front/rear dual view images, implementing reverse image display, breaking through the limitations of traditional viewing angles; Laser measurement technology assists in determining the size of defects.

▶ Dark Night Penetration: Built in high brightness adjustable LED light source system, suitable for complex pipeline environments. Facing the dark space, it can also penetrate through the cover with strong force, making every hidden danger exposed.

▶ Precision meter measuring device: equipped with a precision meter measuring device, real-time recording of detection distance and defect location, with an error of less than ± 0.1cm.

The high-definition pipeline inspection robot can deeply identify defects such as corrosion, cracks, deformation, and sediment on the inner wall of the pipeline. By quantifying the risk level through scientific data, factories can accurately set maintenance priorities:

✅ Preventive maintenance - intervene in high-risk areas in advance to avoid sudden leaks and production shutdowns

✅ Cost Actuarial - Reduce blind excavation and improve maintenance efficiency by over 60%

✅ Compliance management - complete traceability of testing data to meet safety production audit requirements

✅ Extended lifespan - Scientific maintenance of pipeline systems

The Jiutai HB-GTR120A series pipeline inspection robot redefines industrial pipeline operation and maintenance standards with its hardcore strength of "detection is diagnosis". Choosing us means choosing a reliable future of safe production, low-cost operation and maintenance, and sustainable operation!