-

E-mail

409070541@qq.com

-

Phone

18065929385

-

Address

No. 38-3 Xinhua Road, Siming District, Xiamen City

Xiamen Dace Environmental Protection Equipment Co., Ltd

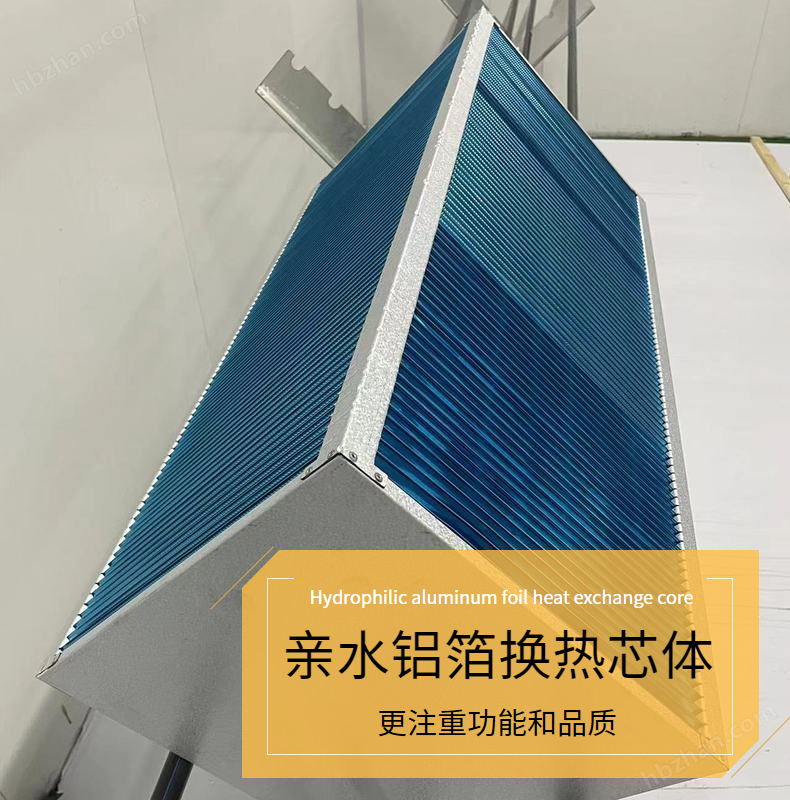

Plate type energy recovery heat exchanger sensible heat exchange core

- Model

- Nature of the Manufacturer

- Producers

- Product Category

- Place of Origin

Plate type energy recovery heat exchanger sensible heat exchange coreIt is the core functional component of the plate type energy recovery heat exchanger, designed specifically for the sensible heat recovery needs of industries such as chemical, construction, electronics, and pharmaceuticals. It is a key supporting product for improving energy utilization efficiency and reducing operating costs.

The product flexibly selects materials according to the application scenario. 304 stainless steel is used in conventional environments, which has good corrosion resistance and thermal conductivity. Titanium alloy is used in harsh medium environments, which has stronger acid and alkali resistance. The substrate is precision cold-rolled and stamped, and the plate thickness is controlled between 0.5~1.0mm, balancing structural strength and thermal conductivity efficiency.

The production process undergoes multiple quality checks such as pressure resistance testing, leakage testing, and heat transfer efficiency testing to ensure that each product meets the design standards.

It adopts a combination structure of corrugated plates, and the surface corrugated design not only increases the heat transfer area, but also guides the medium to form a turbulent state, breaks the heat transfer boundary layer, and makes heat transfer more complete and efficient. The sensible heat recovery efficiency can reach over 80%.

The plates are sealed with sealing gaskets, which are made of high temperature resistant and aging resistant silicone rubber or fluororubber materials. The sealing performance is excellent, effectively preventing medium leakage and flow.

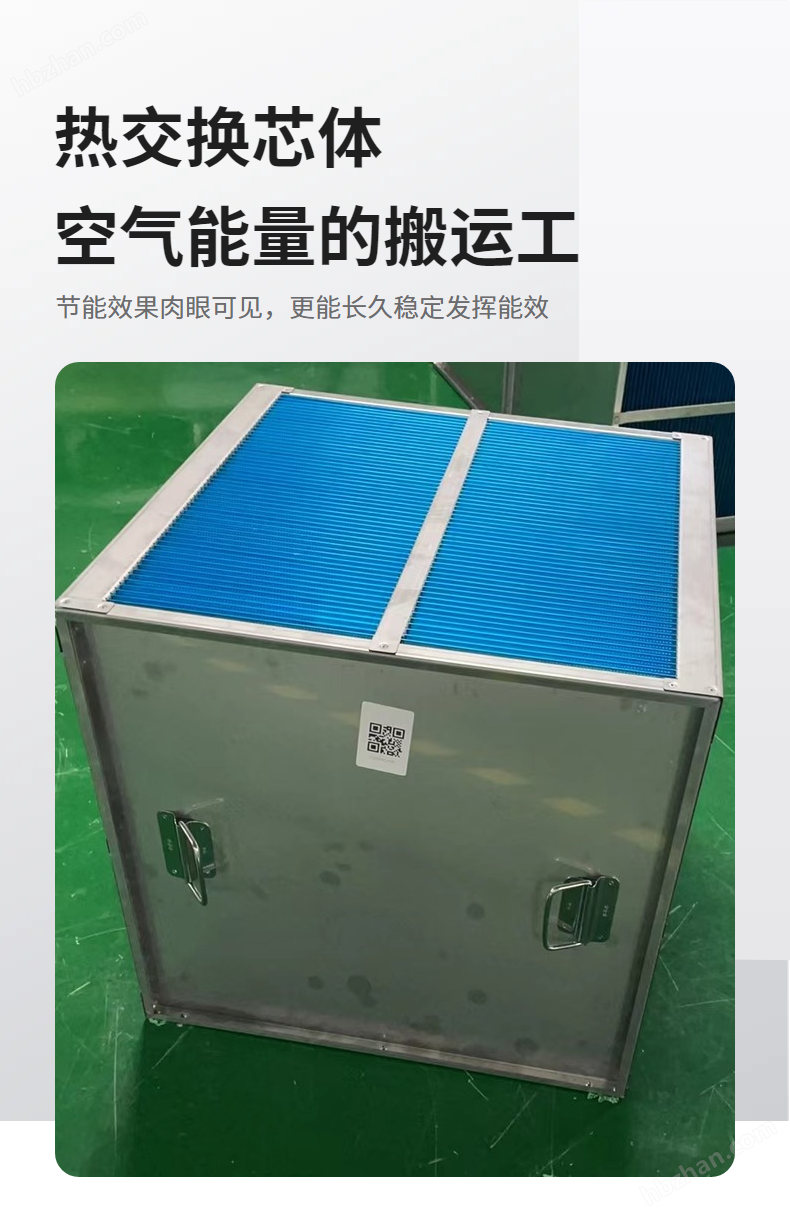

ButPlate type energy recovery heat exchanger sensible heat exchange coreThe cross flow layout allows the cold and hot media to flow in opposite directions on both sides of the plate, further improving the heat transfer temperature difference and enhancing the overall heat transfer effect.

This product can customize parameters such as plate quantity, core size, interface specifications, etc., and is suitable for various scenarios such as chemical reaction kettle heat recovery, building HVAC waste heat utilization, and electronic factory constant temperature control.

Easy to install, can be directly embedded into existing equipment, does not require large-scale modifications, has low operation and maintenance costs, only needs to regularly check the cleanliness of the sealing gasket and plate, and rinse if necessary, which can effectively reduce downtime for maintenance and ensure the continuous and stable operation of the system.

By using this product, enterprises can improve their energy recovery efficiency by an average of over 25%, significantly reducing energy consumption and operating costs, while also reducing carbon emissions. This meets the requirements of national green development policies and provides reliable support for enterprises to achieve energy conservation and consumption reduction.