-

E-mail

3a968@163.com

-

Phone

15821975681

-

Address

118 Wanyong Road

Shanghai Yuhe Valve Industry Co., Ltd

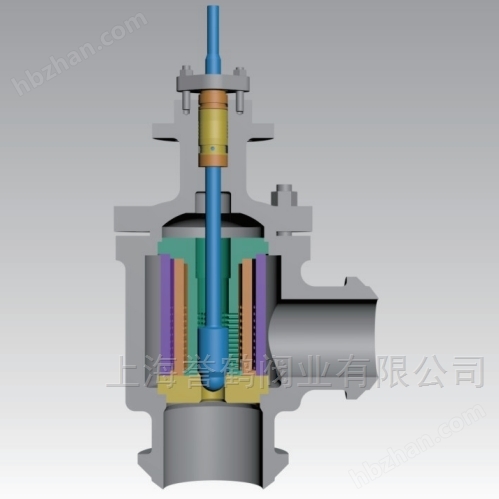

Pneumatic high-pressure cage type angle regulating valve

- Model

- Nature of the Manufacturer

- Producers

- Product Category

- Place of Origin

Our goal is to become a trusted valve consultant for users. Shanghai Yuhe Valve IndustryPneumatic high-pressure cage type angle regulating valveIt is a pressure balanced regulating valve equipped with multi spring diaphragm pneumatic. Nominal diameter: DN20-400mm; Nominal pressure: PN64-PN160, ANSI 600-1500LB, valve material: 22052507904L, 1.4529254SMo, titanium, C276, Monel, 304, 316, WCB。

Pneumatic high-pressure cage type angle regulating valveValve body material

High temperature materials: When selecting high temperature materials, it is necessary to fully consider the issues of high temperature strength, metallographic structure changes at high temperatures, and corrosion resistance. Generally, alloy steel materials are required to contain chromium, nickel, and molybdenum elements. In addition, under high temperature and pressure, steel is corroded by hydrogen gas, which generally causes decarburization and embrittlement. After adding metal elements such as chromium, nickel, and molybdenum to steel, it combines with carbon elements to improve the steel's resistance to hydrogen corrosion.

Low temperature materials: When selecting low-temperature materials, it is necessary to fully consider the low-temperature impact value of the material, as well as the brittleness problem of the material's toughness decrease at low temperatures. Therefore, materials used in low-temperature conditions must have sufficient toughness at low temperatures, and the steel selected for valves at different temperatures must meet the standard specified impact energy at the applicable temperature in order to be safe and reliable. Austenitic stainless steel is often used due to its stable low-temperature mechanical properties.

Parameter Description

Valve cover form: standard type, high temperature heat dissipation type, low temperature type, corrugated pipe;

Cover type: bolt compression type;

Packing: polytetrafluoroethylene, graphite;

Valve core type: pressure balanced valve core;

Valve action types: positive action, reverse action, gas closed, gas open;

Pneumatic accessories: locator, air filter pressure reducer, holding valve, travel switch, valve position transmitter, handwheel mechanism.

Traffic characteristics: equal percentage, linear, fast opening;

Flange sealing surface: RF, RJ, MFM;

Flange standards: JIS B2201, ANSI B16.5, JB/T79.1, JB/T79.2, HG/T20592;

Leakage level: According to the American National Standards/Fluid Control Organization ANSI/FCI 70-2 "Control Valve Seat Leakage" standard,

ANSI/FCI 70-2-2013 V (Standard Metal Seat)

ANSI/FCI 70-2-2013 VI (Cut off Soft Seat)

Pipeline connection methods: flange type, butt welding type

Applicable temperature range: -196 ℃ -570 ℃

Technical Specifications

Nominal diameter: DN20-400mm;

Nominal pressure: PN1.6, 4.0, 6.4MPa;

Flange standards: JB/T79.1-94, 79.2-94, HG/T20592, GB/T9119, etc;

Valve material: 22052507904L, 1.4529254SMo, titanium, C276, Monel, 304, 316, WCB。