-

E-mail

1217030773@qq.com

-

Phone

19157135090

-

Address

Workshop 3 of Oulong Technology Park

Shandong Youyunpu Optoelectronics Technology Co., Ltd

Portable industrial non-destructive testing instrument

- Model

- Nature of the Manufacturer

- Producers

- Product Category

- Place of Origin

Portable industrial non-destructive testing instrumentProduct Overview:

Portable industrial non-destructive testing instrumentIt can quickly, conveniently, non destructively, and accurately detect, locate, evaluate, and diagnose various internal defects of workpieces such as cracks, welds, pores, sand holes, inclusions, folds, etc. It is widely used in fields such as power, petrochemicals, boiler pressure vessels, steel structures, aerospace, railway transportation, automobiles, and machinery. It is an important instrument in the testing industry.

Main functions:

1. High precision quantitative and positioning, suitable for the requirements of near and far distance inspection;

2. Small near-field blind zone, suitable for the requirements of small diameter and thin-walled tube inspection;

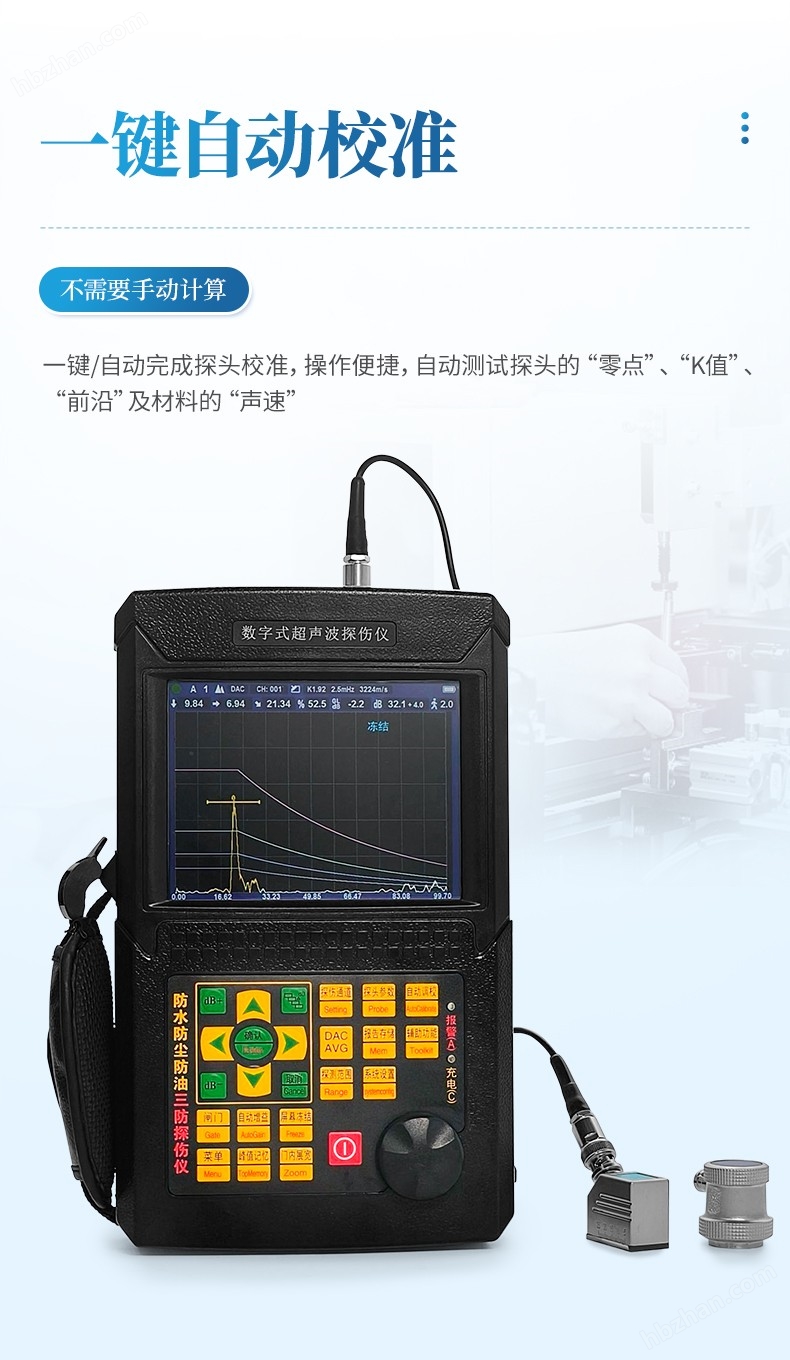

3. Automatic calibration: One click automatic calibration, easy to operate, automatically tests the "zero point", "K value", "leading edge" of the probe and the "sound velocity" of the material;

4. Automatically display the location of defect echoes (depth d, horizontal p, distance s, amplitude, equivalent dB, aperture ф value);

5. Free switching of three scales (depth d, horizontal p, distance s);

6. The automatic gain, echo envelope, and peak memory functions have improved the efficiency of flaw detection;

7. Calculation of diameter: Straight probe forging flaw detection, automatic conversion of aperture ф value to find the highest wave of defects, automatic calculation of large flat bottom;

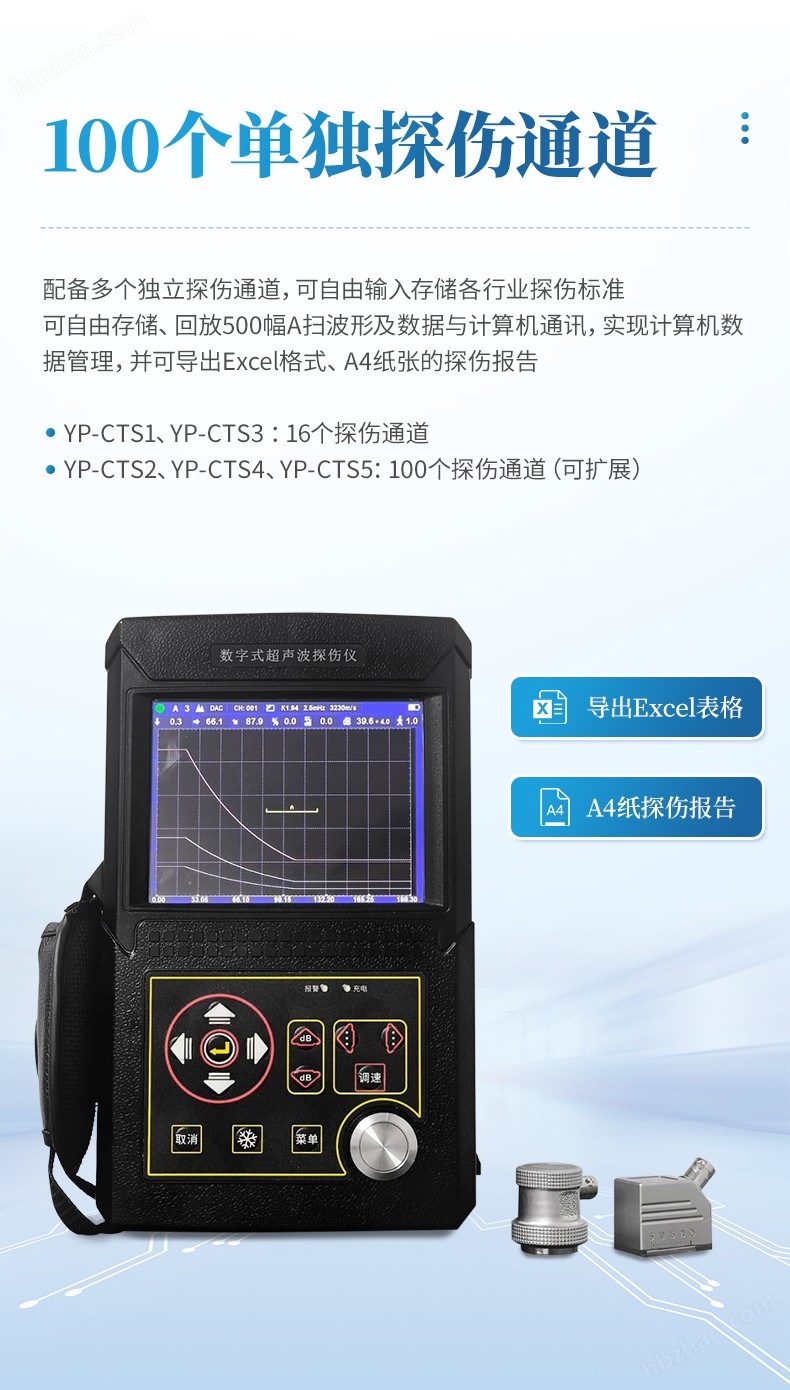

8. 100 individual flaw detection channels (expandable), which can freely input and store flaw detection standards from any industry, and on-site flaw detection does not require carrying test blocks;

Free storage and playback of 500 A-scan waveforms and data;

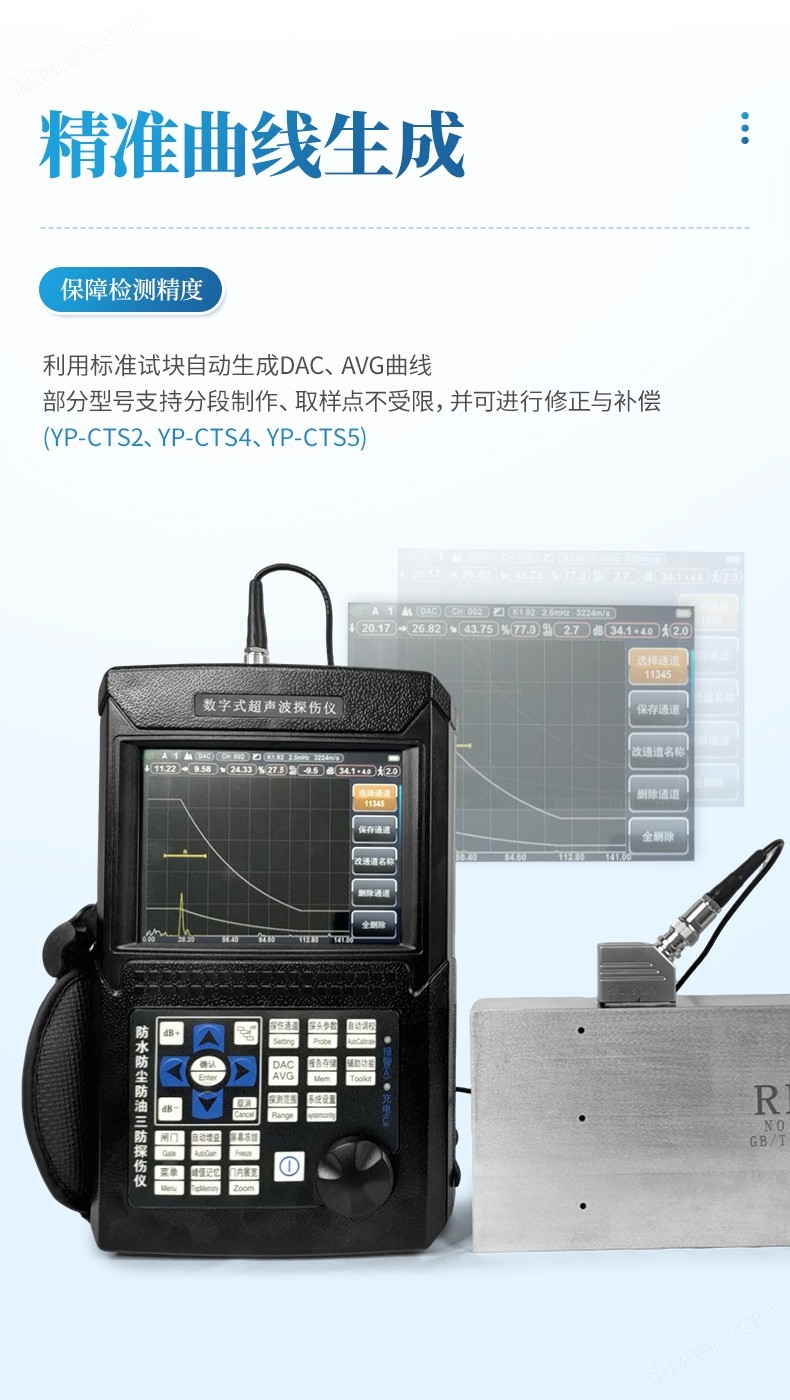

9. DAC and AVG are automatically generated and can be segmented, with unlimited sampling points that can be corrected and compensated;

10. 13 built-in flaw detection standards can be adjusted out;

11. You can freely input any industry standard;

12. The pulse width and intensity of the emission can be adjusted;

13. Communicate with computers, achieve computer data management, and export flaw detection reports in Excel format and A4 paper;

14. IP65 standard aluminum magnesium alloy shell, sturdy and low wear, waterproof and dustproof, good anti-interference ability;

15. 260000 color true color screen with ultra-high brightness display, adjustable brightness, suitable for working environments with strong and weak light;

16. Powered by lithium batteries with safe and environmentally friendly performance, it can work continuously for 10 hours.

17. Real time clock recording: track and store the real-time detection date and time;

18. Power off protection ensures that stored data is not lost;

19. The flaw detection parameters can be automatically tested or pre-set;

20. Digital suppression does not affect gain and linearity;

21. Gain compensation: The Db attenuation caused by factors such as surface roughness, curved surfaces, and long-distance inspection of thick workpieces can be corrected.

22. The true three proof design can ensure that users are not corroded by rainwater, oil, dust, etc. in complex sites and wilderness, greatly extending the service life of the flaw detector.

Auxiliary functions:

1. Two input methods: angle and K value

2. Echo frequency analysis

3. Power status indication

4. Gate sound and light alarm

5. DAC sound and light alarm

6. Freezing and thawing of screens

7. Clock display

Product Features:

1. The buttons are simple and easy to operate;

2. The large screen highlights can meet the requirements of non-destructive testing in sunlight and culverts.