-

E-mail

409070541@qq.com

-

Phone

18065929385

-

Address

No. 38-3 Xinhua Road, Siming District, Xiamen City

Xiamen Dace Environmental Protection Equipment Co., Ltd

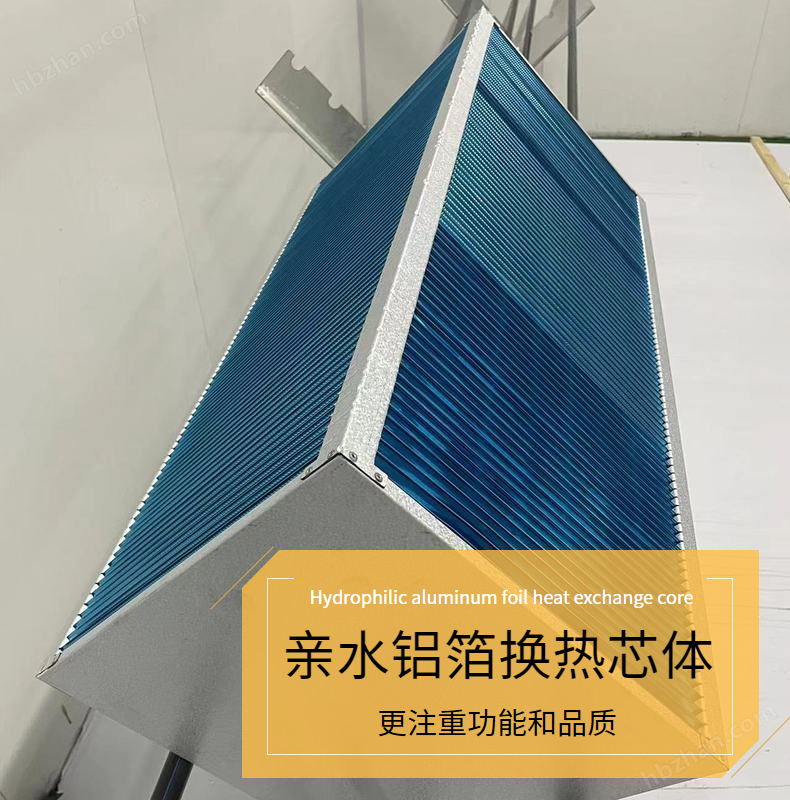

Pre cooler plate fin heat exchanger core

- Model

- Nature of the Manufacturer

- Producers

- Product Category

- Place of Origin

Pre cooler plate fin heat exchanger coreIt is the core functional component of the pre cooler, designed specifically for pre cooling conditions such as cold chain systems, industrial refrigeration, and compressed air pretreatment. With efficient heat transfer performance and compact structure, it has become the key core of pre cooling equipment.

The product uses high-quality 304 stainless steel or aluminum alloy as the core material, which can be flexibly adapted according to different pre cooling media and temperature requirements. The material has a wide temperature resistance range (-40 ℃~200 ℃), good thermal conductivity and corrosion resistance, and can adapt to complex working environments such as cold chain logistics and industrial refrigeration.

During the production process, precision machining and strict testing are carried out to ensure structural accuracy and stability in use.

Adopting the classic plate fin structure design, consisting of partitions, fins, and seals, the fins adopt a corrugated or serrated structure to expand the heat transfer area. Compared with traditional tube heat exchange cores, the heat transfer efficiency is increased by more than 40%.

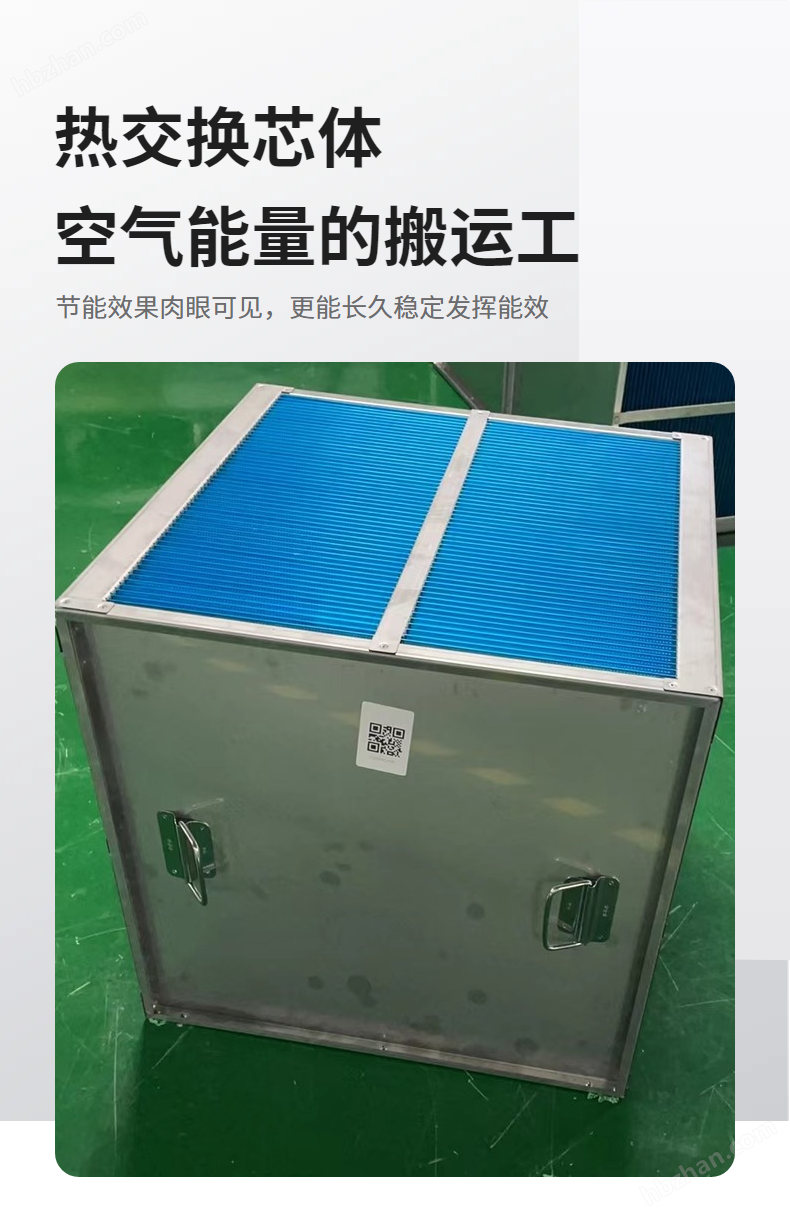

At the same time, it has a compact structure and high space utilization, which can achieve efficient heat transfer within limited installation space. The internal flow channel design of the core is reasonable, and the cold and hot media flow separately in their respective channels, with low flow resistance and uniform heat transfer. It can quickly reduce the temperature of the medium to the preset range, ensuring stable and efficient operation of the pre cooling ring.

Pre cooler plate fin heat exchanger coreSupport customized production, adjust the size of the core, fin spacing, interface specifications, etc. according to the model, processing capacity, working pressure and other parameters of the pre cooler, and adapt to scenarios such as cold chain storage refrigeration equipment, industrial compressed air pretreatment systems, chemical reaction kettle pre cooling devices, etc.

The installation process is simple and convenient, without the need for complex auxiliary tools. Only professional personnel need to fix it according to the positioning requirements. The subsequent maintenance cost is low, and only regular cleaning of impurities and scaling in the flow channel is required to ensure long-term stable operation.

By using this product, the heat exchange efficiency of the pre cooling equipment can be effectively improved, the energy consumption of the refrigeration system can be reduced, the average operating cost can be reduced by 20% to 30%, and the overall service life of the pre cooling equipment can be extended. It is an ideal supporting component for improving equipment performance and achieving energy conservation and consumption reduction in the cold chain and industrial refrigeration fields. All performance indicators of the product meet industry standards, and the quality is reliable and guaranteed.