-

E-mail

970805072@qq.com

-

Phone

15838053733

-

Address

No. 99, Jingsan Road North, Jinshui District, Zhengzhou City

Zhengzhou Jiutai Technology Co., Ltd

Professional pipeline endoscope

- Model

- Nature of the Manufacturer

- Producers

- Product Category

- Place of Origin

Professional pipeline endoscopeOne machine has multiple capabilities and understands a hundred rules! Jiutai Technology empowers industrial grade full scene precision detection

In the hidden "blood vessels" of industrial equipment and infrastructure, hidden dangers often go unnoticed. Traditional detection methods are time-consuming, labor-intensive, costly, and even require shutdown and disassembly, seriously affecting production and operational efficiency. Jiutai Technology, with its 360 ° high-definition camera gimbal, "one machine for multiple uses" technology advantages, and "full coverage of industrial scenes" adaptability, has become your versatile eye for efficiently observing the health inside pipelines!

GM300 seriesProfessional pipeline endoscopeIt is a high-precision visual inspection equipment designed specifically for the industrial inspection fieldpremiumIts performance and wide applicability make it an important tool in modern industrial maintenance and quality control systems. The core advantage of this device is its ability to easily handle various industrial pipeline systems with diameters ranging from 7mm to 800mm, while also being suitable for small space detection tasks inside complex structural equipment. It can clearly capture key information such as corrosion marks, fine cracks, welding seam quality, deposited foreign objects, surface wear patterns, and internal processing defects of components on the inner wall of the pipeline. Through high-resolution imaging technology, inspectors can systematically evaluate the internal status of equipment, promptly identify potential safety hazards, and provide reliable basis for predictive maintenance. It is particularly prominent in application scenarios such as boiler pipeline inspection in the energy and power industry, pipeline inspection in the petrochemical industry, hydraulic system inspection in manufacturing enterprises, and engine cavity inspection in aerospace and military equipment.

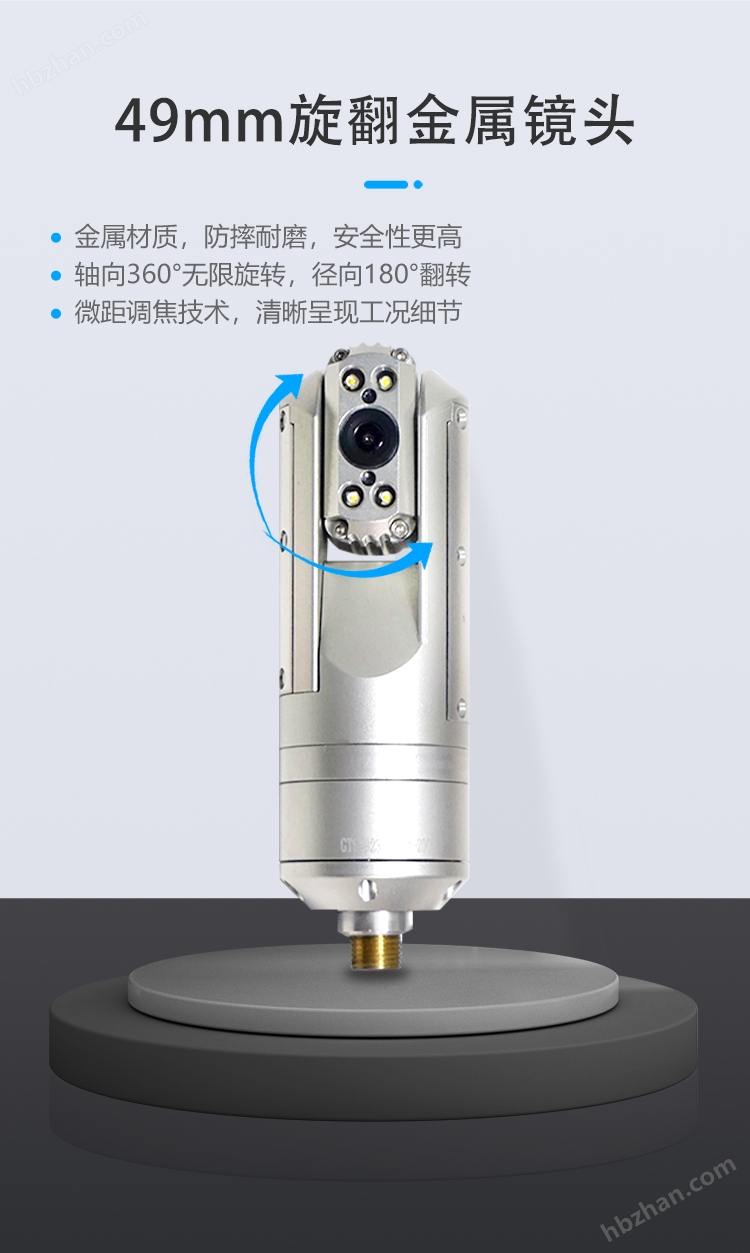

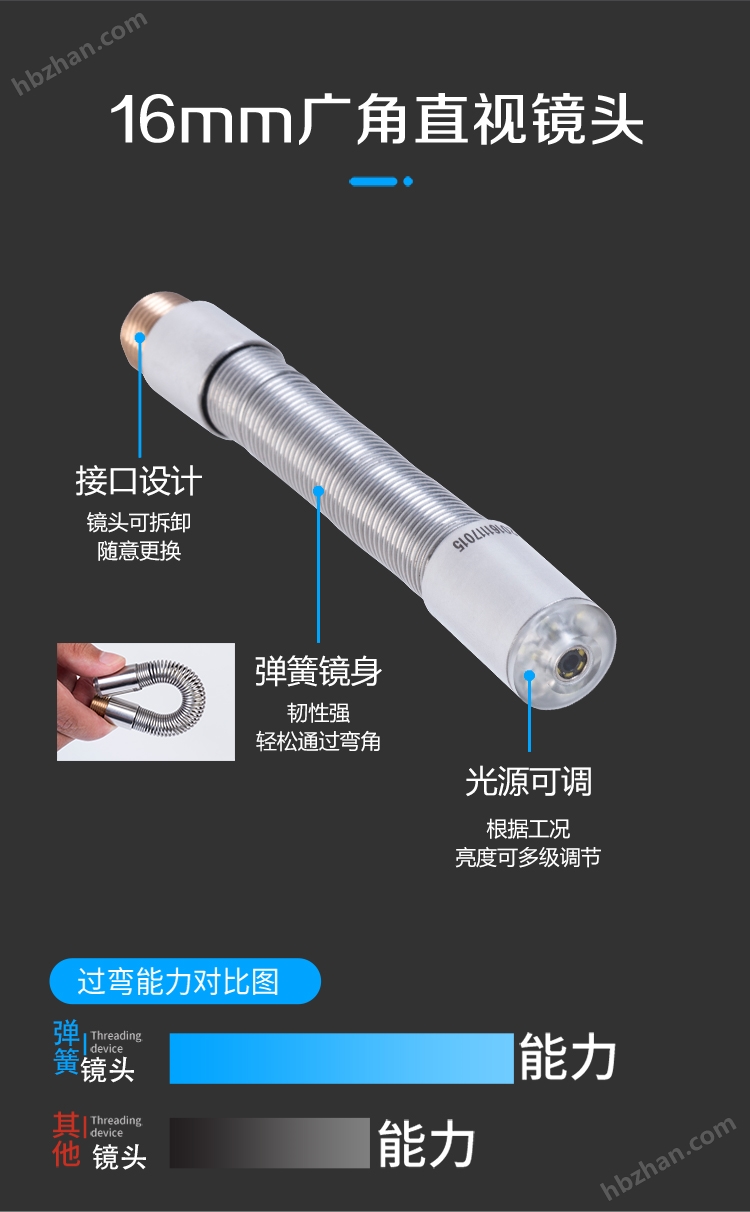

GM300 series high-definition industrial endoscopeEquipped with a 7-inch IPS full view industrial grade high-definition LCD touch screen,Whether in outdoor environments with strong light or inside devices with dim lighting, clear images with realistic colors and rich details can be presented. The humanized touch interaction design makes the operation process more intuitive and convenient, greatly improving the efficiency of on-site detection.Equipped with professional defect measurement function, data is displayed in real-time and recorded in image/video data,Combined with intelligent image processing software, users can perform detection on captured imagesMulti level editing processing, including adding arrow indications, text annotations, area markers, and other graffiti operations,Provide strong material support for equipment status tracking and quality traceability.Even more rare is its excellent system compatibility. The device supports combinations of eight or more different specifications of detection lenses, forming a complete detection solution system. This modular design concept enables users to meet the detection needs of various complex scenarios with only one set of hosts, significantly improving equipment utilization and return on investment.

As industrial production advances towards "safer, more efficient, and more intelligent", Jiutai Technology's industrial pipeline endoscope is playing the role of an "all-round inspector" and installing "health monitors" on every industrial pipeline. Penetrating the steel barrier and identifying micro level hidden dangers is not only an innovation in detection tools, but also an upgrade in industrial safety management mode - making hidden risks visible, shifting passive repair to active prevention, and ultimately safeguarding the stable operation of every production link. Jiutai Technology, with 15 years of experience in intelligent pipeline inspection technology, provides you with high-definition industrial pipeline endoscope solutions that are clear, accurate, and cost-effective to use. Let us penetrate the darkness, identify hidden dangers, and jointly safeguard the health and safety of the industrial pulse!