-

E-mail

984573880@qq.com

-

Phone

18953674999

-

Address

No. 2, 1688, 1st row, No. 888 Gao'er Road, Weifang Comprehensive Bonded Zone (registered address)

Shandong Senyang Environmental Technology Co., Ltd

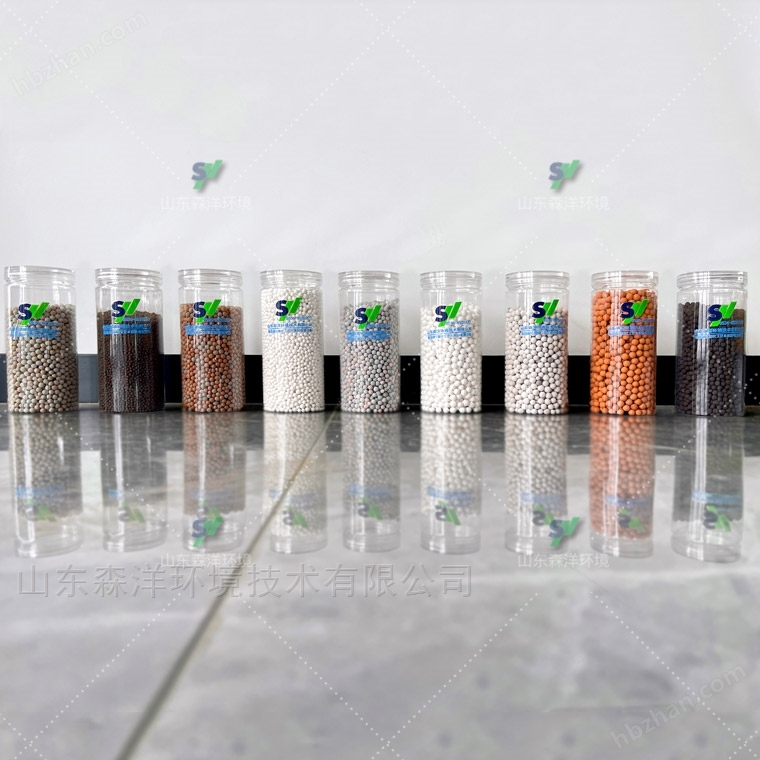

Senyang Environment produces ozone catalyst

- Model

- Nature of the Manufacturer

- Producers

- Product Category

- Place of Origin

1Senyang Environment produces ozone catalystCore advantages of ozone catalysts

1. Innovation in Materials and Processes

-Carrier optimization: using modified porous alumina or ceramic substrate as the carrier, with a specific surface area of200-400m²/g, load**Rare earth metals (such asMnTheCoTheCe)**And transition metal oxides enhance the density of active sites.

-Composite sintering process: through high-temperature sintering(800-1200Forming a stable crystal structure (℃) and improving mechanical strength2-3Double, excellent anti erosion performance, with a service life of up to3-5Year.

2. Efficient catalytic performance

-Ozone utilization efficiency improvement: catalytic decomposition of ozone to produce reactive oxygen species (ROS)·OThe·OHReduce the utilization rate of ozone from traditional processes, etc30%upgrade to**80%Above, significantly reducing the amount of ozone added (saving)40%-60%).

-Broad spectrum degradation ability:

- CODremoval rate60%-90%Especially for difficult to degrade organic compounds such as benzene derivatives, phenols, antibiotics, etc;

-Decolorization rate>95%Effectively destroying the chromophore groups of dye molecules;

-Simultaneous removal of ammonia nitrogen (removal rate)50%-70%)And some heavy metals.

3. Economy and environmental friendliness

-Low operating costs: reducing ozone usage and energy consumption (lowering water treatment costs per ton)30%-50%)Decreased sludge production40%

-No secondary pollution: stable catalyst composition, no metal leaching, reaction products areCO₂ andH₂ONo need for secondary neutralization.

4. Strong environmental adaptability

-widepHScope: AdaptationpH 3-9Reduce the acid-base regulation process;

-Resistant to high salt and high chlorine: tolerantTDS≤8%TheCl⁻≤15g/LSuitable for desalination of concentrated seawater and electroplating wastewater;

-Anti pollution impact**Even if water entersCODFluctuations (such as3000mg/LSudden increase10000mg/L)It can still operate stably.

-2、 Typical application industries and scenarios of ozone catalysts produced by Senyang Environment

1. Chemical and petrochemical industry

-Application scenario: Processing highly toxic wastewater containing benzene derivatives, phenols, pesticide intermediates, etc., such as petroleum refining wastewater and coking wastewater.

-Typical case: Treatment of epoxy resin wastewater in a chemical plant,CODfrom5000mg/Ldrop to800mg/LDecolorization rate98%

2. Printing and dyeing and textile industry

-Application scenario: Degradation of reactive dye and dispersed dye wastewater, decolorization and reductionCODEnhance biodegradability.

-Technical highlight: Combined with microelectrolysis process, forming a "pretreatment (decolorization)+Deep oxidation(CODRemove the entire process plan.

3. Pharmaceutical and Medical Industry

-Application scenario: Processing wastewater containing antibiotics, hormones, and chemical raw materials, and cracking difficult to degrade organic compounds.

-Case reference: Wastewater from a certain antibiotic pharmaceutical factoryCODfrom8000mg/Ldrop to1200mg/L,B/CCompared to from0.1upgrade to0.35

4. Municipal and garbage leachate

-Application scenarios: Deep treatment of trace pollutants in municipal wastewater (such as drug residues, endocrine disruptors), degradation of humic acid in leachate from garbage.

-Advantages reflected: Modular design adapted to the renovation of old water plants, reducing land occupation40%

5. Electroplating and Electronics Industry

-Application scenario: Simultaneous degradation of chelating agents in electroplating wastewater (such as...)EDTA)And organic matter, assisting in the removal of heavy metals.

6. Food and Brewing Industry

-Application scenario: Processing high concentration organic wastewater (such as starch wastewater, fermentation wastewater), reducingCODAnd decolorize.