-

E-mail

liuyanhe@zhderx.com

-

Phone

13005602816

-

Address

Zhuhai New Olin Technology Park

- Acetone wastewater low-temperature evaporation treatment equipment

- Sodium sulfate mixed salt solution dryer

- Polyethylene glycol wastewater concentration equipment

- Dimethyl sulfoxide wastewater treatment equipment

- Organic solvent wastewater concentration treatment equipment

- Wastewater phosphoric acid recovery equipment

- Mother liquor drying machine

- Electroplating wastewater evaporation crystallization equipment

Zhuhai Derunxin General Machinery Co., Ltd

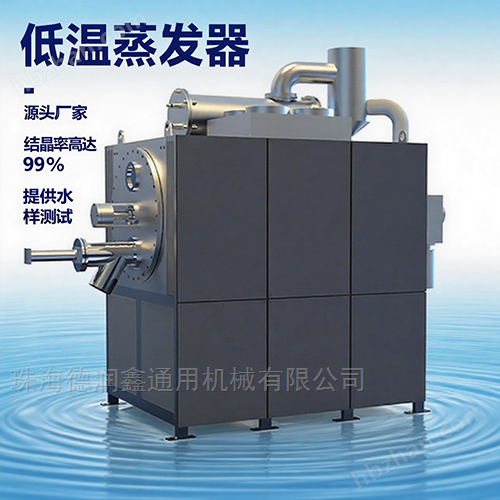

Sodium sulfate mixed salt solution dryer

- Model

- Nature of the Manufacturer

- Producers

- Product Category

- Place of Origin

working principle

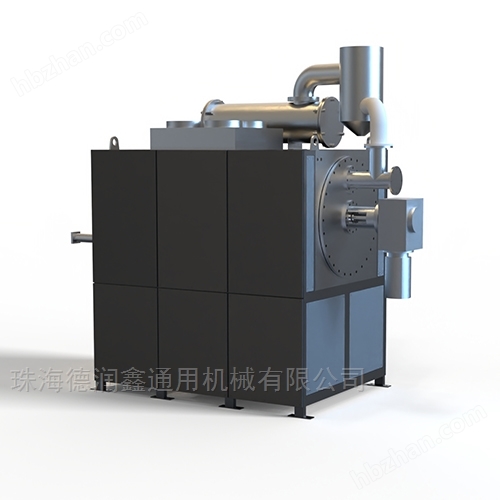

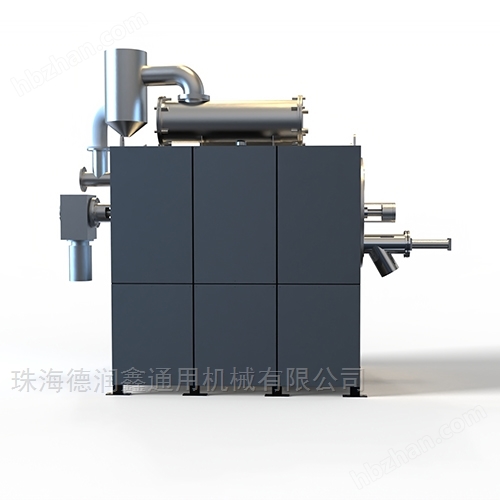

Sodium sulfate mixed salt solution dryerFirstly, pretreat the sodium sulfate mixed salt solution by filtering to remove suspended impurities and prevent clogging of the drying system. The pre treated solution enters the low-temperature drying chamber, where the boiling point of low water (usually 40-60 ℃) is lowered in a vacuum environment. Combined with the low-temperature heat source provided by the heat pump system, the water in the solution gradually evaporates into steam. Steam enters the condensation system and condenses into liquid water, which is reused or discharged after meeting the standards. As the water continues to evaporate, the concentration of sodium sulfate and mixed salts in the solution gradually increases, eventually forming solid dry material, which is discharged from the drying chamber through a scraper or screw conveyor device. The dried solid salt can be further separated and purified according to demand to achieve resource recovery.

Features of the equipment

Low temperature drying, energy-saving and efficient:Sodium sulfate mixed salt solution dryerAdopting heat pump low-temperature drying technology, it saves more than 50% energy compared to traditional high-temperature drying equipment, significantly reduces operating costs, and is suitable for continuous processing scenarios.

Low temperature evaporation, high capacity reduction rate: It can fully evaporate the water in the solution, and the moisture content of solid dry materials can be as low as 5% or less, with a capacity reduction rate of over 80%, greatly reducing the amount of solid waste disposal.

Corrosion resistant and wear-resistant, long-lasting: The parts in contact with the solution are made of corrosion-resistant and wear-resistant materials such as 2205 duplex steel and Hastelloy alloy, which can withstand the corrosion and wear of high concentration salt solutions and extend the service life of the equipment.

Intelligent control, easy to operate: equipped with PLC intelligent control system, real-time monitoring of temperature, humidity, vacuum degree and other parameters, automatic adjustment of drying process, achieving fully automatic operation and reducing manual intervention.

Environmental compliance standards, no secondary pollution: no exhaust gas emissions during the drying process, excellent condensate water quality, meeting reuse or emission standards; Solid dry materials are easy to collect and process, with no risk of secondary pollution.

Strong adaptability and flexible processing: It can adapt to different concentrations and ratios of sodium sulfate mixed salt solutions, and can be flexibly configured according to the processing capacity (5-500m ³/d), making installation and debugging convenient.

Classic Case

A chemical enterprise's sodium sulfate mixed salt solution treatment project: The enterprise produces 60m ³ of sodium sulfate mixed salt solution per day, with a sodium sulfate concentration of about 15000mg/L and other salt concentrations of about 8000mg/L. After using this drying machine, the solid salt produced by drying has a moisture content of 4%, producing about 1.8 tons of dry material per day. After separation and purification, the purity of sodium sulfate reaches over 95% and can be reused for production, saving approximately 600000 yuan in raw material costs annually; All condensed water is reused, saving an annual water cost of 200000 yuan. After treatment, all indicators meet environmental protection requirements.

A mixed salt solution treatment project for a pharmaceutical factory: targeting the mixed salt solution containing sodium sulfate, ammonium chloride, etc. (total salt concentration 25000mg/L) produced by the factory, the solid volume reduction rate after equipment drying is 85%, the dry material is easy to transport and dispose of, and the COD of condensed water is reduced to below 50mg/L for standard discharge, solving the problem of mixed salt solution treatment in the enterprise and passing the acceptance of the environmental protection department.