-

E-mail

409070541@qq.com

-

Phone

18065929385

-

Address

No. 38-3 Xinhua Road, Siming District, Xiamen City

Product Categories

Xiamen Dace Environmental Protection Equipment Co., Ltd

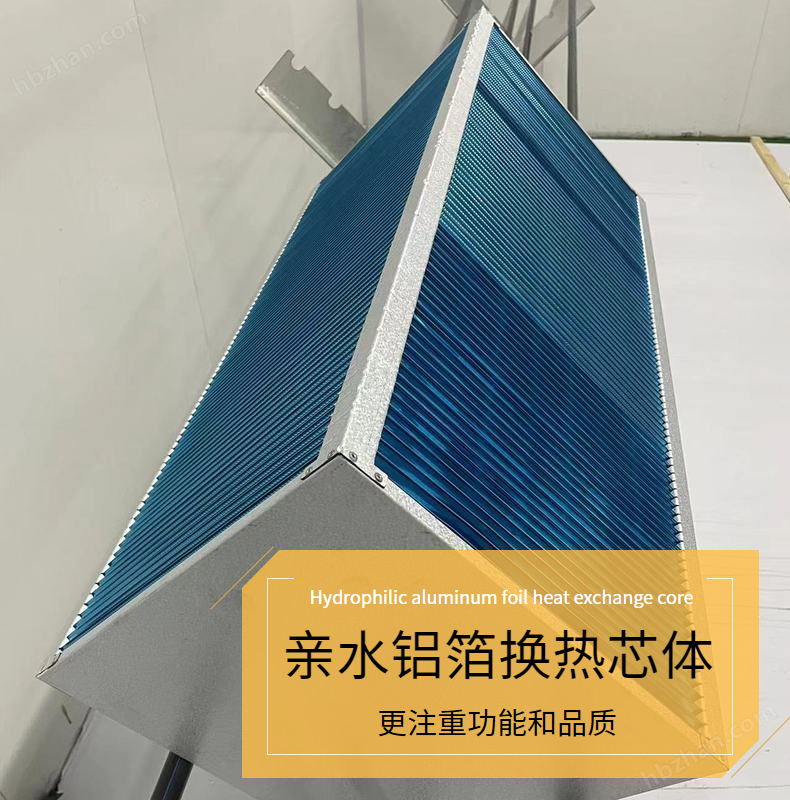

Special accessories for aluminum foil heat exchanger core for waste heat recovery of gas gas heat exchanger

NegotiableUpdate on 01/31

- Model

- Nature of the Manufacturer

- Producers

- Product Category

- Place of Origin

Overview

The aluminum foil heat exchanger core specialized accessory for waste heat recovery of gas and gas heat exchangers is made of high-quality aluminum foil as the core material, combined with precision molding technology to adapt to the waste heat recovery scenario of gas and gas heat exchangers. It combines the advantages of lightweight and efficient heat exchange, helps reduce energy loss, and is the preferred accessory for industrial energy-saving transformation.

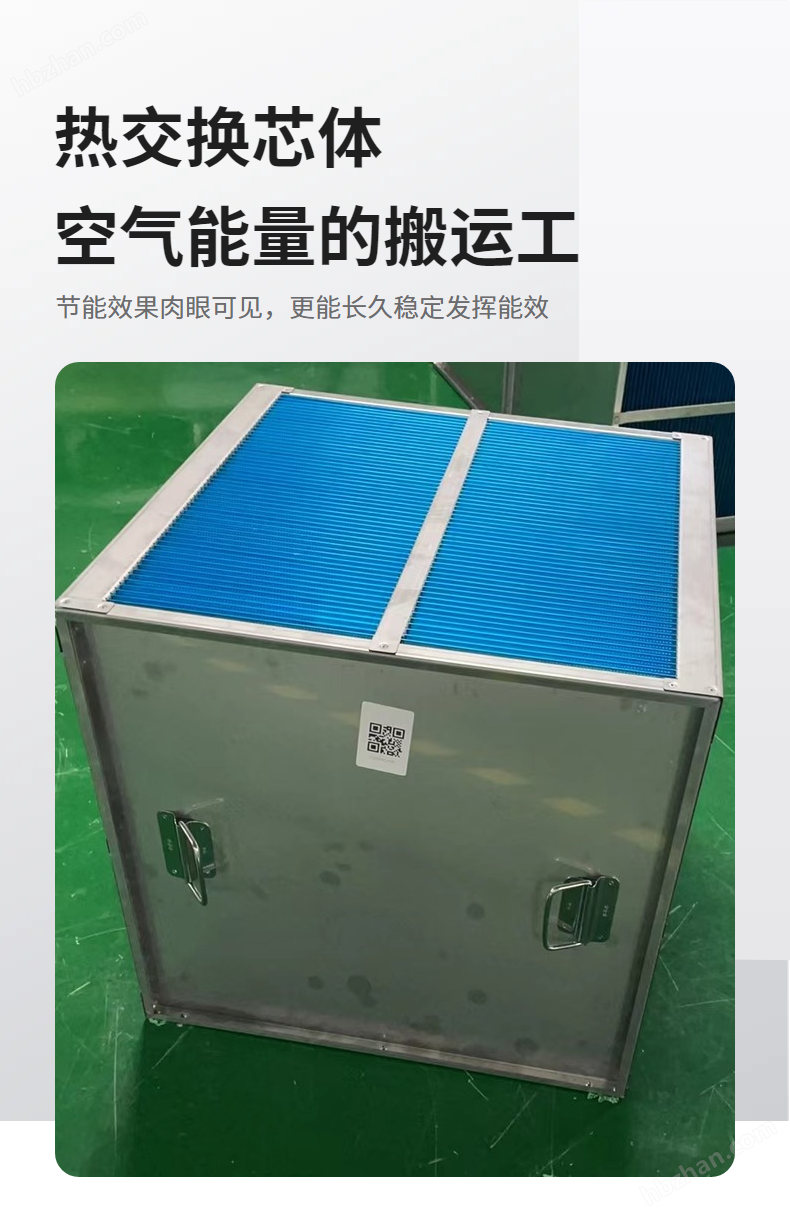

Product Details

Special accessories for aluminum foil heat exchanger core for waste heat recovery of gas gas heat exchangerThe core advantage of the product lies in the deep integration of high-quality materials and precision craftsmanship, with each design centered around "efficient heat transfer, stability, and durability". The selected material is high thermal conductivity aluminum foil with a purity of 99.5%. This aluminum foil has a thermal conductivity coefficient of up to 237W/(m · K), far exceeding that of ordinary carbon steel (45W/(m · K)) and stainless steel (16W/(m · K)). It can quickly transfer energy from cold and hot fluids in a short period of time, reducing heat loss; At the same time, the surface of the aluminum foil undergoes three layers of passivation treatment to form a corrosion-resistant protective film with a thickness of about 5 μ m, which can withstand high temperature conditions of 200 ℃ -300 ℃, as well as corrosive components such as sulfides and nitrogen oxides commonly found in industrial exhaust gas. After third-party testing, the corrosion rate was only 0.02mm/year in a continuous 1200 hour simulated adverse environment test, and the service life was extended by 2-3 times compared to ordinary aluminum foil heat exchange cores. In terms of process, precision stamping equipment imported from Germany is used, with stamping accuracy controlled at ± 0.05mm to ensure the consistency of the size of each channel. At the same time, laser welding technology is used to seal the interface, with a leakage rate of less than 1 × 10 ⁻⁶ Pa · m ³/s, to avoid safety hazards and reduced heat transfer efficiency caused by gas leakage.

In terms of heat transfer performance and adaptability, the design of this accessory is more in line with industrial practical needs. The honeycomb channel structure optimized through fluid dynamics simulation increases the contact area between cold and hot fluids to 1.8 times that of traditional plate heat exchangers. At the same time, the channel section adopts a gradient design, with a wide inlet end and a narrow outlet end, which not only reduces fluid resistance (the resistance coefficient is reduced by 35% compared to ordinary structures), but also ensures sufficient heat exchange. Actual test data shows that when processing industrial exhaust gas with a temperature of 150 ℃ and a flow rate of 2000m ³/h, the waste heat recovery rate of this component can reach over 68%, far exceeding the industry average of 50%. The adaptation scenarios cover multiple fields such as chemical engineering, electricity, metallurgy, HVAC, etc. For example, in the tail gas treatment of reaction vessels in chemical enterprises, the recovered waste heat can be used to preheat raw materials, reducing heating energy consumption by 40%; In the boiler flue gas recovery of thermal power plants, it can provide 70% of the heat demand for the heating system in the plant area. In addition, the accessories support modular customization, and the length (range 300mm-2000mm), width (range 200mm-1500mm), and channel density (range 50-120 holes/square decimeter) can be adjusted according to the model and size of the heat exchanger. During installation, there is no need for large-scale modification of existing equipment, only standard flange connections are required, and a single person can complete the replacement within 2 hours, greatly reducing the transformation time and labor costs of enterprises.

Its energy-saving value and economic benefits have been verified in numerous practical application cases. After introducing this component in 2023, a large steel enterprise saved 120000 cubic meters of natural gas consumption through waste heat recovery in just 6 months, equivalent to a cost of about 480000 yuan, while reducing carbon dioxide emissions by 260 tons, successfully meeting the emission reduction requirements of the local environmental protection department; A certain food processing factory uses this accessory to recycle high-temperature exhaust gas from the baking workshop, providing preheating energy for the workshop air conditioning system, reducing the power consumption of the air conditioning unit by 28%, and saving over 150000 yuan in annual electricity costs. In addition to saving direct energy costs, the long-life characteristics of the accessories also reduce maintenance frequency. Traditional heat exchange cores need to be replaced every 1.5 years on average, while this accessory can be replaced every 3-4 years under normal use, reducing the number of maintenance shutdowns and providing strong support for enterprises to ensure continuous production.

Special accessories for aluminum foil heat exchanger core for waste heat recovery of gas gas heat exchangerBased on material advantages, guaranteed by precision craftsmanship, and centered on high efficiency performance, this not only provides practical and feasible energy-saving solutions for enterprises, but also aligns with the current trend of green development under the "dual carbon" goal, becoming an important support for promoting energy efficiency utilization and achieving cost reduction and efficiency improvement in the industrial sector.