-

E-mail

1085299140@qq.com

-

Phone

15102122322

-

Address

No. 7833 Hangnan Road, Zhuangxing European Industrial Park, Fengxian District, Shanghai

Shanghai Xinji Cable Co., Ltd

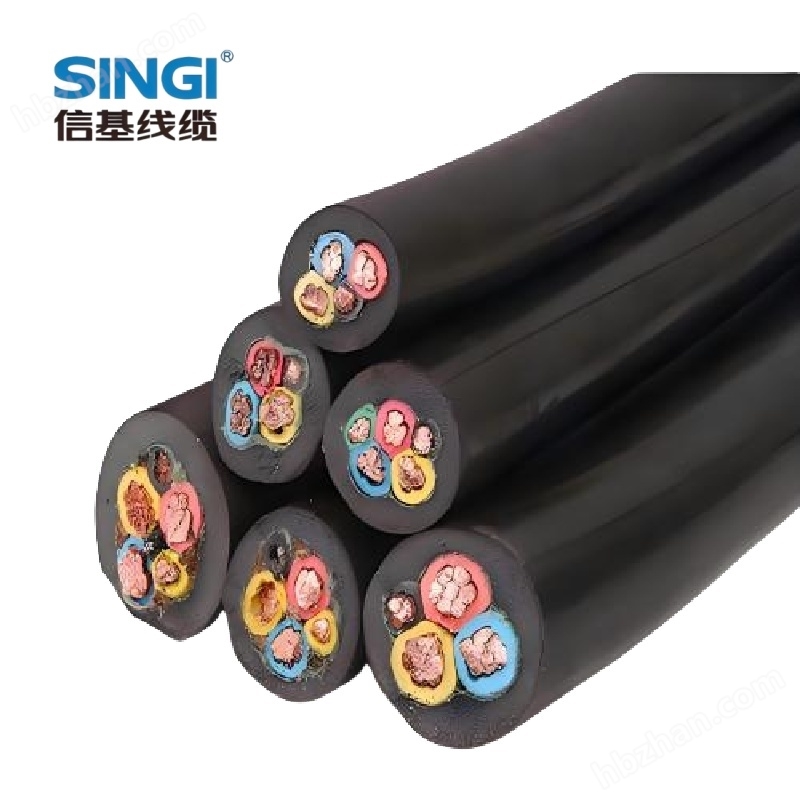

Special drum cable for grab bucket

- Model

- Nature of the Manufacturer

- Producers

- Product Category

- Place of Origin

Special drum cable for grab bucket

1、 Product performance

2、 Core materials

Conductor: Multiple strands of ultra-fine bare copper stranded wire (oxygen free copper material) are selected, which complies with DIN VDE 0295 Class 5 or 6, IEC 60228 Class 5, and GB/T3956 Class 5 standards. Through the process of untwisting and twisting, it has excellent conductivity and flexibility, ensuring that it does not break under frequent bending;

Core wire insulation: Made of special high-strength modified elastomer flame retardant material, PVC-J-105-003 (2105-LF) or special oil resistant flame retardant mixed nitrile PVC insulation material, with strong insulation performance, excellent aging resistance and temperature resistance, effectively avoiding short circuits between core wires;

Strengthening and buffering structure: Built in yellow hemp rope filling, galvanized steel wire rope or Kevlar tensile fiber combination tensile elements, some models add polyester weaving or Kevlar anti twist weaving layer, the core wire and protective sleeve are wrapped in non-woven buffer layer to absorb tensile and torsional stress and protect the internal structure;

Inner sheath: made of DQPVC-H-90-003 (9039-LF) or high-strength TPE based mixed material, with good sealing and buffering properties, further enhancing the ability to resist mechanical damage;

Outer sheath: Imported or high-quality PUR (polyurethane) material is selected, which has low adhesion, high wear resistance, tear resistance, as well as oil resistance, corrosion resistance, and UV resistance, and can adapt to the erosion of harsh working environments such as ports and garbage disposal sites.

3、 Core parameter table

parameter category |

specific parameters |

|---|---|

rated voltage |

450/750V、0.6/1kV |

test voltage |

2.5kV (450/750V specification), 3.5kV (0.6/1kV specification) |

temperature range |

Fixed installation: -40 ℃~+80 ℃; Mobile installation: -25 ℃~+80 ℃ (customized models can be expanded to -60 ℃~+150 ℃) |

bend radius |

Mobile: 7.5 x cable outer diameter; Fixed: 10 x cable outer diameter |

tensile load |

25N/mm² |

Twisted stress |

±50°/m |

movement speed |

180m/min |

Core wire identification |

≤ 5 cores: colored wire cores (compliant with VDE 0293-308 standard); ≥ 6 cores: Black core with white numerical code, including yellow green grounding protection wire (optional) |

Flame retardant rating |

Compliant with VDE 0472-804 Class B and IEC 60332-1 standards |

Eco-Certification |

Compliant with RoHS, 2014/35/EU Guideline (Low Voltage Directive) CE certification |

4、 Product Usage:Special drum cable for grab bucket

Port logistics field: Port gantry crane grab, container loading and unloading grab, ship crane grab, dock loading and unloading grab equipment;

Environmental protection field: garbage crane grab, slag crane grab, cleaning machine grab, sewage treatment plant salvage grab;

Industrial lifting field: tower crane grab, gantry crane grab, bridge crane grab, cantilever crane grab;

Other heavy working conditions: mobile heavy machinery equipment with drum/reel devices, such as raw material grab buckets in the metallurgical industry, mining grab bucket equipment, and material transfer grab buckets in chemical industrial parks.

5、 Packaging method

Cable winding: Standard cable reels (made of wood or steel) are used for winding and packaging. The diameter of the reels is matched according to the cable specifications to ensure that the cables are not twisted or squeezed. The length of each reel is usually 50m or 100m, and special lengths such as 75m or 80m can be customized according to customer needs;

Protective treatment: The outer layer of the cable is wrapped with waterproof PE film or non-woven fabric to prevent moisture, dust, or scratches from sharp objects during transportation; Install protective barriers on both sides of the cable reel to prevent wear and tear on the edges of the cables;

Fixation and identification: The cable reel is fixed with steel strips or bolts to prevent rolling during transportation; Each package comes with a product label indicating key parameters such as model, specifications, length, production batch number, execution standards, manufacturer information, etc;

Transportation adaptation: The packaging meets the requirements of various transportation modes such as road, railway, and sea freight, and customized packaging can be provided according to customer needs (such as export specific fumigation wooden plates, waterproof reinforced packaging, etc.).

6、 Product advantages

Strong adaptability to working conditions: specially designed for dynamic operations such as frequent winding, stretching, and twisting of grab machines, with excellent fatigue resistance and a service life 3-5 times longer than ordinary cables, significantly reducing replacement frequency and maintenance costs;

Comprehensive environmental tolerance: The combination of PUR outer sheath and specialized insulation material achieves comprehensive protection against oil, acid, alkali, UV, and high and low temperature adaptation. It can be stably applied in harsh environments such as ports, garbage dumps, and metallurgical plants;

Structural design science: adopting a composite structure of "reinforced conductor+central tensile member+anti twist braided layer+double sheath", effectively absorbing tensile and torsional stress, avoiding cable bulging, core breakage, and skin cracking, and ensuring the stability of power supply and signal transmission;

Cost control optimization: Compared to traditional rubber cables, it has a smaller outer diameter and lighter weight, and can be adapted to small-sized reels and guide wheels, reducing equipment driving force consumption; Customized production from the source factory, short delivery cycle, reducing inventory backlog;

Safety and compliance guarantee: Through multiple international and domestic certifications, the flame retardant, environmental protection, and insulation performance meet the standards, reducing safety risks such as electric shock and fire during the operation process; Clear identification of core wires for easy installation and maintenance;

Outstanding customization ability: It can customize the conductor cross-section, number of cores, sheath material, length and other parameters according to the actual working conditions of customers (such as complex temperature, ultra long distance, special tensile requirements) to meet personalized needs.

7、 After sales service

Pre sales consultation: A professional technical team provides working condition matching consulting services, recommends excellent cable models and specifications based on customer grab machine models, operating environments, and usage needs, and provides technical parameter tables and selection plans;

In sales support: Provide free sample testing services to ensure that products meet actual needs; Arrange technical personnel to assist customers with installation guidance, answer technical questions during the installation process, and ensure installation standards;

Quality assurance: The product provides a 12-24 month quality warranty period. During the warranty period, if there are any quality problems with the product itself (not caused by human damage or excessive working conditions), free repair and replacement services will be provided; Support third-party compliance agencies for quality testing. If the testing fails, a full refund will be issued and the testing costs will be borne;

After sales response: Establish a 24-hour after-sales service hotline, and provide preliminary solutions within 1 hour after receiving customer feedback on issues; If on-site service is required, arrive within 24 hours in the surrounding areas and within 48 hours in remote areas;

Value added services: Provide cable usage and maintenance training services, guide customers to store, use, and maintain cables correctly, and extend the service life of cables; Long term provision of spare parts supply services to ensure the continuous operation of customer equipment;

Customized service guarantee: Provide specialized technical support for customized products, track production progress throughout the process, and ensure that the products meet customized requirements; Customized technical documentation is provided upon delivery to facilitate customer use and maintenance.

The product price is for reference only. If you need to inquire, please contact the homepage sales~