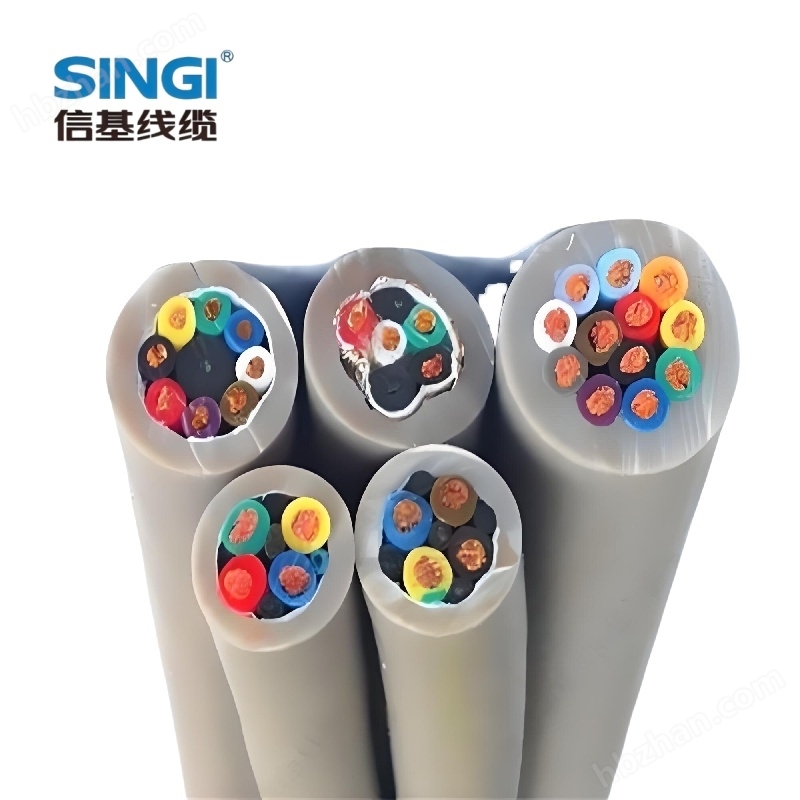

Special high-temperature and wear-resistant drum cable for steel mills, designed for high temperature and strong wear conditions in steel mills. It uses high-temperature resistant alloy conductors and double-layer PUR wear-resistant sheaths, with a built-in steel wire tensile layer. It can withstand temperatures up to 120-260 ℃ and resist repeated winding, bending, and mechanical friction. Suitable for equipment such as converters, blast furnaces, and steel rolling lines, it can stably transmit power signals in high-temperature dust environments, meet the high-frequency movement requirements of drum winding, and is a reliable wiring choice for core equipment in steel mills.

Steel plant specific high-temperature and wear-resistant drum cable

1、 Product performance

High temperature resistance: The temperature range covers 120 ℃ -260 ℃, and it can operate stably in high-temperature environments near steelmaking furnaces and blast furnaces for a long time. It can withstand a peak temperature of 300 ℃ for a short period of time.

Wear and tear resistance: The double-layer PUR sheath material is resistant to repeated friction and drag, with a wear resistance level of Tire A standard, meeting the high-frequency winding and bending requirements of the drum.

Tensile and torsional performance: Built in high-strength steel wire braided armor layer, tensile strength ≥ 15kN, excellent torsional performance, suitable for mobile equipment such as steel carts.

Weather resistant and corrosion-resistant: resistant to steel mill dust, oil stains, acid and alkali steam erosion, with a protection level of IP65, suitable for harsh industrial environments.

2、 Core materials

| structural part |

Material Selection |

Performance Function |

| conductor |

High temperature and oxygen free copper alloy |

Reduce resistance and improve conductivity stability in high-temperature environments |

| insulating layer |

Cross linked polyolefin (XLPO) |

High temperature resistance, breakdown resistance, insulation resistance ≥ 100M Ω· km |

| Sheath layer |

Double layer wear-resistant PUR+ceramic fireproof layer |

Wear resistant and tear resistant, forming a ceramic like protective layer during a fire to prevent the spread of flames |

| Tensile reinforcement layer |

High galvanized steel wire weaving |

Enhance cable tensile performance and extend winding service life |

3、 Technical parameter table

| parameter category |

technical indicators |

| rated voltage |

0.6/1kV、3.6/6kV |

| temperature rating |

120 ℃ (economy type), 150 ℃ (standard type), 200 ℃ (high-performance type), 260 ℃ (customized type) |

| bend radius |

Fixed laying ≥ 6 x cable outer diameter, mobile laying ≥ 10 x cable outer diameter |

| insulation thickness |

1.0mm-3.5mm (according to cross-sectional specifications) |

| sheath thickness |

2.0mm-4.0mm (double-layer structure) |

| Applicable temperature range |

-40℃~ +260℃ |

4、 Common models

Economy type: YVFR-G-0.6/1kV 3 × 10+1 × 6 (temperature resistance of 120 ℃, ordinary PUR sheath)

Standard type: YVFR22-G-0.6/1kV 3 × 25+1 × 16 (temperature resistance 150 ℃, steel wire armor)

High performance type: YGVFR-G-3.6/6kV 3 × 70+1 × 35 (temperature resistance of 200 ℃, ceramic fireproof layer)

Customized type: YGVFRH-G-3.6/6kV multi-core combination (temperature resistance 260 ℃, alloy conductor)

Steel plant specific high-temperature and wear-resistant drum cable

5、 Applicable purpose

Core high-temperature equipment: converter, blast furnace feeding system, steelmaking furnace area trolley, ladle transport vehicle.

Steel rolling production line: rolling mill drum drive equipment, roller conveyor line mobile power supply.

Auxiliary supporting equipment: raw material conveyor belt conveyor, dust removal system mobile control cabinet power supply signal transmission.

6、 Packaging method

Inner packaging: The cable is wrapped with moisture-proof oil paper and sealed with waterproof sheaths at both ends to prevent water and dust from entering during transportation.

Outer packaging: Made of thickened corrugated cardboard boxes and wrapped with wooden I-shaped wheels. The specifications of the I-shaped wheels are adapted to the length of the cable (100 meters/wheel, 500 meters/wheel, 1000 meters/wheel).

Identification information: Each round of cable is accompanied by a product certificate, indicating the model, specifications, length, temperature resistance level, production date, and implementation standards.

7、 Product advantages

Strong adaptability to working conditions: specially designed for high temperature, high wear, and high dust environments in steel mills, the service life is extended by 3-5 times compared to general drum cables.

Outstanding safety performance: The ceramic fireproof layer does not melt in the event of fire and meets the GB/T 19666-2019 flame retardant standard, reducing the risk of fire.

Easy installation and maintenance: Good flexibility, small bending radius, can directly adapt to various types of drum equipment, reducing installation and debugging time.

Full specification coverage: from economical to customized, meeting the diverse needs of steel mills for different equipment and working conditions.

8、 After sales service

Quality assurance: The product has a warranty period of 2 years. If any quality problems occur during the warranty period due to non-human damage, a new product will be replaced free of charge.

Technical support: Provide free on-site installation guidance, cable selection scheme design, supporting technical manuals and installation drawings.

Quick response: Set up a 24-hour after-sales service hotline, and arrange technical personnel to be on site within 48 hours after receiving a fault report for repair.

Lifetime maintenance: After the warranty period, we provide cost based repair and parts replacement services, and regularly follow up with customers to understand the product's operational status.

The product price is for reference only. If you need to inquire, please contact the homepage sales~