The dust filter cartridge of the sweeping car vacuum cleaner is 320 * 800, which can efficiently intercept the intake dust, protect the sweeping car fan and motor, and reduce the risk of failure and energy loss caused by dust wear. Low initial resistance combined with self-cleaning function can maintain low operating resistance for a long time, reduce fan loading losses, and improve equipment operating efficiency.

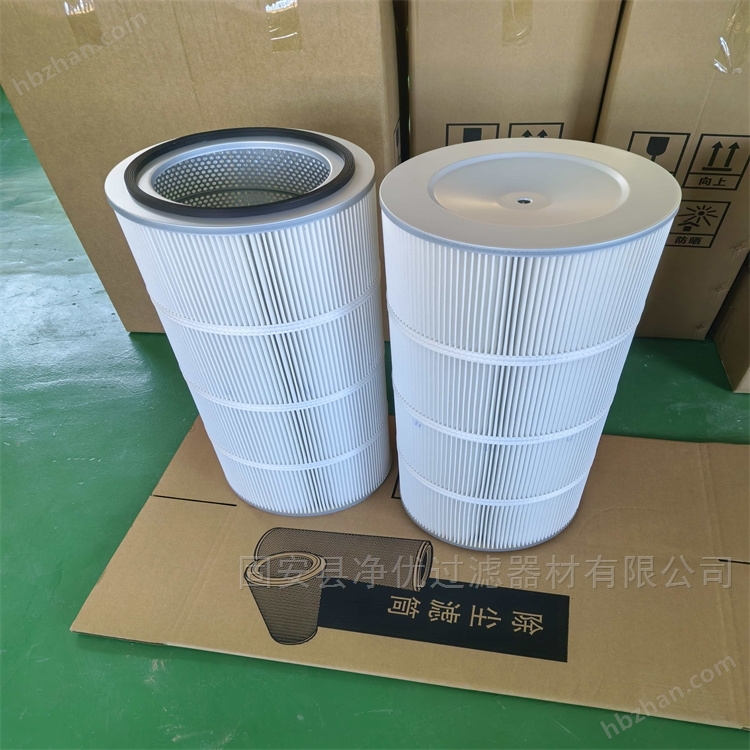

Sweeping car, vacuum cleaner, dust filter cartridge 320 * 800

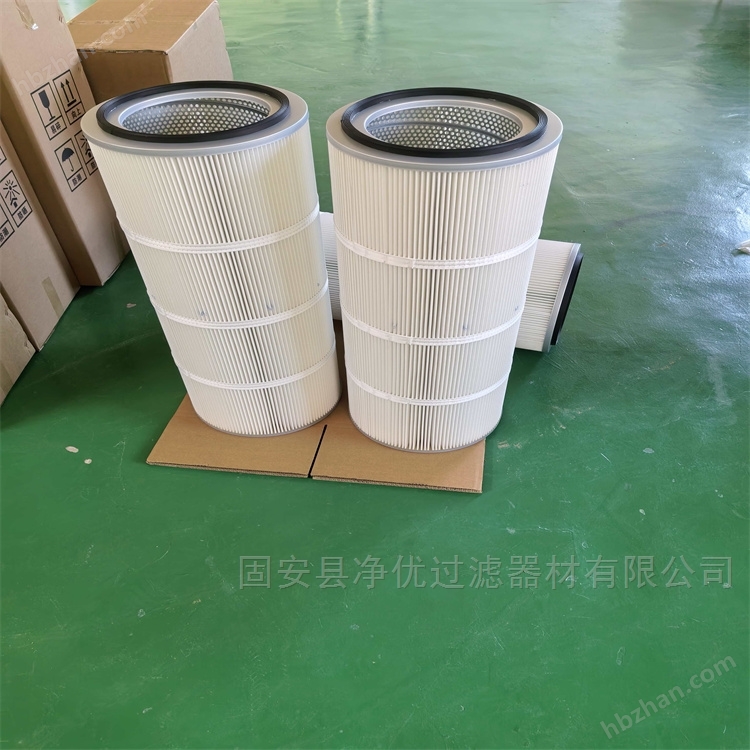

Jingyou Filter 320 × 800 is a self-cleaning dust filter cartridge specially designed for sweeping and vacuuming vehicles, with an outer diameter of 320mm and a length of 800mm. It is compatible with mainstream sweeping vehicle flower board openings and uses polyester long fiber non-woven fabric as the core filter material. It is suitable for high-frequency pulse working conditions in environmental sanitation cleaning, efficiently intercepting road dust and self-cleaning through pulse blowback, greatly reducing the maintenance frequency and consumables cost of cleaning equipment.

The effective filtration area of the filter cartridge is about 8 square meters, and it adopts a wide pleat spacing design to meet the high air volume requirements of the sweeping vehicle. The filtration accuracy covers 0.3-5 μ m, with a conventional filtration efficiency of ≥ 99.9%. The PTFE coated version can achieve an efficiency of ≥ 99.99% for 0.3 μ m particles, effectively capturing impurities such as road dust, sand particles, and paper scraps. Initial pressure difference ≤ 120Pa, it is recommended to trigger a pressure difference of 600-800Pa for dust cleaning. Low resistance design can reduce fan load and improve cleaning efficiency. The normal working temperature is -30 ℃~+80 ℃, and the anti-static surface resistance is 10 ⁴ -10 ⁸ Ω, suitable for dry and dusty flammable and explosive risk scenarios. The weight of the filter cartridge is about 3.8kg, and it adopts a six ear quick disassembly structure, which can be easily disassembled by hand without tools, significantly reducing downtime for maintenance.

The filter material is made of polyester long fiber non-woven fabric, which has the characteristics of durability, high breathability, low resistance and easy blowback. The end cap and filter material are tightly bonded with polyurethane foam adhesive, effectively preventing dust leakage. The internal and external support skeleton is made of electroplated galvanized diamond mesh or stainless steel material with a thickness of 0.5mm or more, which has excellent resistance to deformation and collapse, and can withstand pulse blowback impact during cleaning operations. The end is equipped with a closed cell chloroprene rubber sealing ring to ensure no leakage from the equipment flower plate seal and prevent unfiltered air from short circuiting into the system. When the resistance of the filter cartridge reaches the set value, it can be adapted to the built-in pulse back blowing system of the sweeping vehicle. The high-pressure airflow quickly blows off the attached dust from the inside, quickly restoring the filtering performance and reducing the frequency of manual cleaning and replacement.

This filter cartridge can efficiently intercept incoming dust, protect the sweeping car fan and motor, and reduce the risk of failure and energy loss caused by dust wear. Low initial resistance combined with self-cleaning function can maintain low operating resistance for a long time, reduce fan loading losses, and improve equipment operating efficiency. Optional PTFE film anti sticking, anti-static, and flame-retardant customized options are available, suitable for different dust and working environments such as urban main roads, industrial parks, and construction sites, extending the service life of the filter cartridge. Widely applicable to sanitation sweepers, vacuum cleaners, road sweepers, and engineering sweepers, especially suitable for cleaning scenarios with high dust volume and continuous operation.

Conventional road cleaning can choose polyester base version; PTFE film anti sticking is recommended for heavy dust or high humidity working conditions such as construction sites and coal yards to prevent dust adhesion from affecting the cleaning effect; For dry and dusty environments with explosion-proof requirements, it is recommended to choose anti-static or flame-retardant products. During use, it is necessary to cooperate with the pulse system of the cleaning vehicle, regularly check the blowback pressure (0.4-0.6MPa) and cleaning cycle, and ensure that the pressure difference is stable within a reasonable range. It is recommended to conduct integrity testing of filter cartridges every 8-16 months. In complex working conditions, the testing cycle should be shortened to promptly detect and replace damaged filter cartridges, in order to avoid dust leakage affecting filtration efficiency and equipment safety.

Sweeping car, vacuum cleaner, dust filter cartridge 320 * 800