-

E-mail

sales@m-excel.cn

-

Phone

13361898597

-

Address

Building 1, No. 65, Lane 1398, Xinzhu Road, Minhang District, Shanghai

Shanghai Maiyue Environmental Technology Co., Ltd

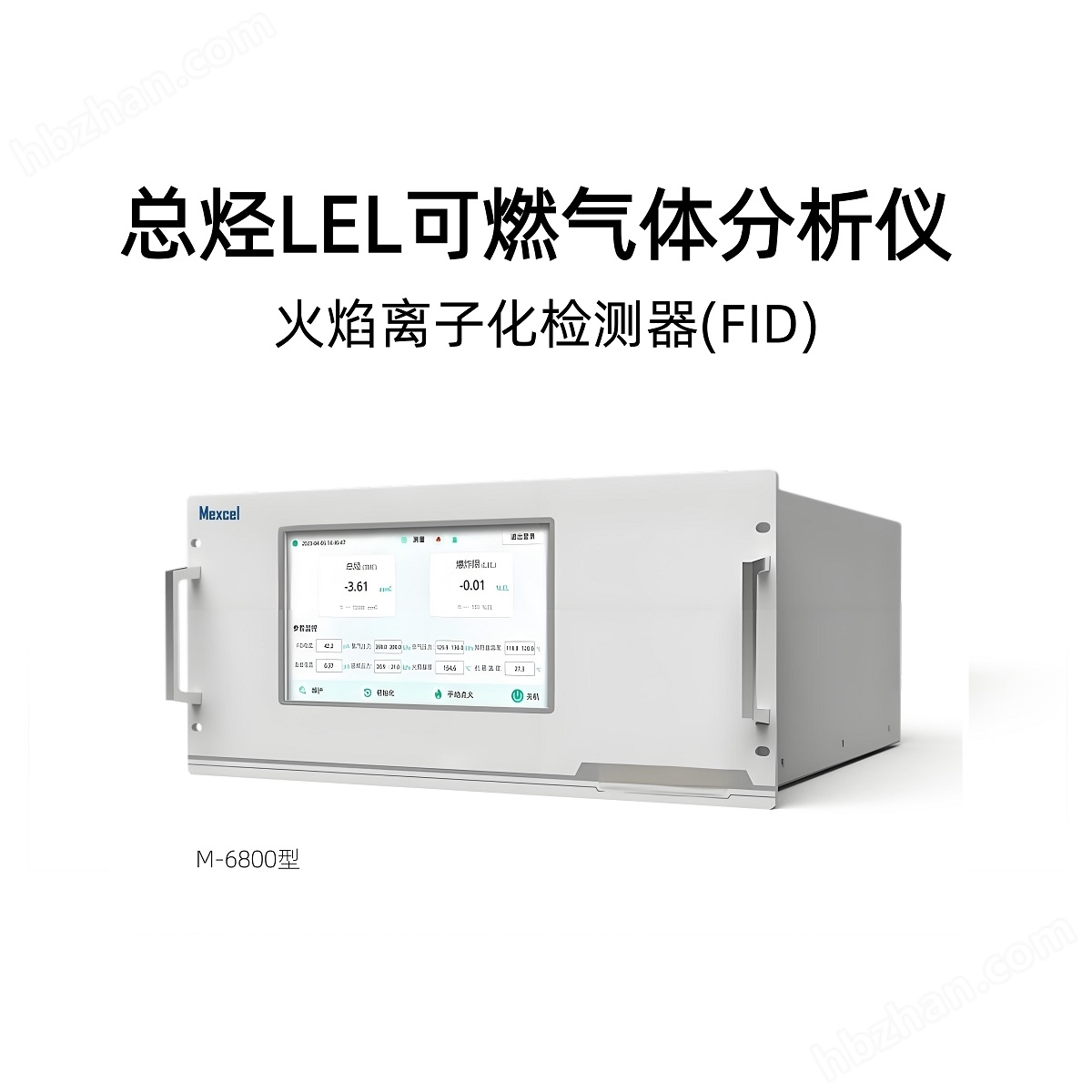

Total hydrocarbon LEL combustible gas analyzer (FID)

- Model

- Nature of the Manufacturer

- Producers

- Product Category

- Place of Origin

M-6800Total hydrocarbon LEL combustible gas analyzer (FID)Using flame ionization detector (FID) technology, it has high sensitivity, good stability, and multiple selectable measurement ranges, suitable for real-time analysis of total hydrocarbon concentration and lower explosive limit (LEL) of various organic gases. It is widely used in RTO inlet LEL explosion limit monitoring, VOC removal device removal efficiency monitoring, THC concentration monitoring, etc.

Product advantages

Total hydrocarbon LEL combustible gas analyzer (FID) It has significant advantages in industries such as pharmaceuticals, chemicals, tobacco, and food packaging.

lFast response time: T90≤2S,Total response time<5S.

lBuilt in high-temperature pump, suitable for low-pressure sampling conditions.

lThe system is heated throughout the entire process to avoid condensation and adsorption of organic matter in the sample gas.

lHigh measurement accuracy, ≤ 1% F.S.

lBuilt in EPC flow control for stability.

lThe response factors for various types of hydrocarbons are close to 1, with stable measurement and high accuracy.

lCan simultaneously output THC concentration and explosion limit LEL value.

technical indicators

table1 Technical indicators

brand |

Shanghai Maiyue Environmental Technology |

Measure components |

Total Hydrocarbons,%LEL |

range |

THC:(0~100000)ppmC LEL0~100)%LEL |

ambient temperature |

(5~40)℃ |

Analyzer heating |

120℃,Other temperatures can be customized |

sampling flow |

0.5SLM~1.5SLM |

repetitiveness |

≤1% |

Analysis cycle |

Real time output |

Zero point and range drift |

≤±2%F.S./24h |

linear error |

≤±1%F.S. |

communication protocol |

Modbus protocol |

model |

M-6800 |

size |

500mm×482(435)mm×213mm(L×W×H) |

weight |

20.5kg |

ambient humidity |

0~95)%RH |

Sample gas |

Sample gas to be tested, injection pressure 80~110kPa (absolute pressure) |

hydrogen |

Purity above 99.99%, supplied by hydrogen cylinder or hydrogen generator, pressure: 04MPa |

air |

Clean air, hydrocarbon concentration ≤ 0.3mg/m3, pressure: 0.4MPa |

Drive gas |

Clean air, hydrocarbon concentration ≤ 0.3mg/m3, pressure: 0.4MPa |

Standard gas |

Pressure requirements0.2MPa |

working power supply |

220 VAC,50Hz |

power |

Start 500W, run 150W |

Product application scenarios

lMeasurement of total carbon and hydrogen in industrial process gases.

lMonitoring of gas concentration at the inlet and outlet of exhaust gas treatment devices (RTO/RCO/incinerators, etc.).

lReal time monitoring of total hydrocarbons in emissions purification and chemical cleaning factories.

lMonitoring of total carbon and hydrogen content in liquid oxygen of air separation unit.

lReal time monitoring of organic matter concentration at the discharge outlet of catalytic, biological, and activated carbon treatment devices.

lReal time monitoring of total hydrocarbons in the conversion of crude gas to clean gas.

lMonitoring and early warning of organic matter leakage during the production process.

lMonitoring and warning of the lower explosive limit of solvent saturated air.