-

E-mail

2582680638@qq.com

-

Phone

18333636533

-

Address

Niutuo, Gu'an County, Langfang City, Hebei Province

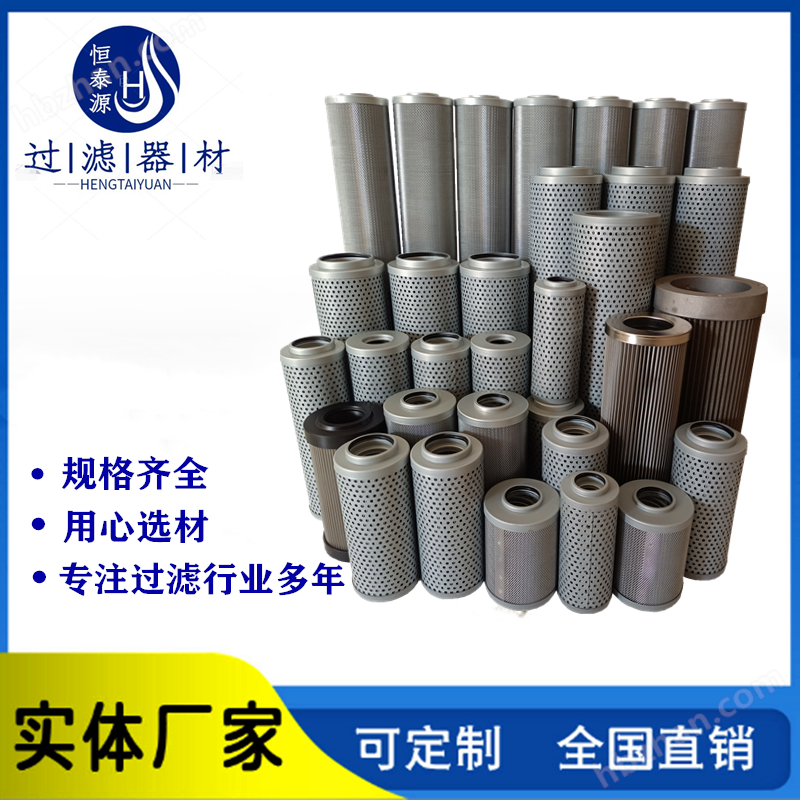

Langfang Hengtaiyuan Filter Equipment Co., Ltd

V3.0720-18 machine hydraulic oil filter element

- Model

- Nature of the Manufacturer

- Producers

- Product Category

- Place of Origin

Produced by Langfang Hengtaiyuan Filter Equipment Co., LtdV3.0510-13 Folding Fiber Filter CartridgeIt is the core component of the filtering system,PE sintered dust removal filter elementUsed to remove impurities (such as particles, microorganisms, oil stains, etc.) from liquids or gases, ensuring the purity of the fluid and the normal operation of the system. Here is aboutV3.0933-18 turbine oil station filter elementDetailed analysis: 1Lithium battery powder filter PE sintered filter cartridgeThe main types

Classified by filter media:

V3.0720-16 Hydraulic Lubrication Oil Circuit Filter Element(Polypropylene, fiberglass): Suitable for particle filtration of liquids such as water and oil.

Metal filter element (stainless steel sintered mesh): resistant to high temperature and high pressure, used in the chemical and food industries.

V3.0720-18 machine hydraulic oil filter elementMicro porous structure, capable of filtering bacteria, commonly used in drinking water purification.

Activated carbon filter cartridge: adsorbates, odors,Membrane filter material bag filter elementMostly used for air or water treatment.

Membrane filter cartridge (ultrafiltration/reverse osmosis membrane): High precision, capable of separating molecular level impurities.

Fan filter, air filter cartridgeClassified by function:

Fuel gas filter stainless steel filter element(5 100 microns): Intercept large particles and protect downstream equipment.

Fine filter element (0.1 5 microns): removes small particles, such as hydraulic oil filtration.

Ultrafiltration filter cartridge (<0.1 microns):V2.0920-08 Hydraulic Oil Filter CartridgeUsed for high-purity fluids such as pharmaceuticals and semiconductors.

2. V3.0510-13 Folding Fiber Filter CartridgeKey performance parameters

Filtering accuracy:V3.0823-26 Pilot filter oil filter elementExpressed in micrometers (μ m), it determines the small particles that can be intercepted.

Differential pressure (Δ P): Blockage of the filter element in the PE vacuum feeder can cause an increase in differential pressure, which needs to be monitored regularly.

Pollutant carrying capacity:V3.0620-58 Fuel Filter ScreenThe lifespan indicator refers to the ability to intercept impurities.

Compatibility:V2.0920-03 Hydraulic Filter CartridgeThe filter material needs to withstand the chemical properties of the fluid, such as acidity, alkalinity, and solvents.

3. Typical application scenarios

V3.0833-03 Gear oil filter elementIndustrial sector:

Hydraulic system: prevents particle wear on precision components.

Lubricating oil filtration:V3.0933-16 Steel Plant Oil Filter Equipment Filter CartridgeExtend the service life of the equipment.

Chemical process: protect the reactor or catalyst.

Civilian field:

Water purifier: filters out sediment, heavy metals, and bacteria.

Air purifier: filters PM2.5, pollen, etc.

PE sintered dust removal filter elementIt is a filtering material widely used for precision filtration of liquids and gases. Here is aboutPolyester fiber folding filter cartridge for separatorDetailed introduction:

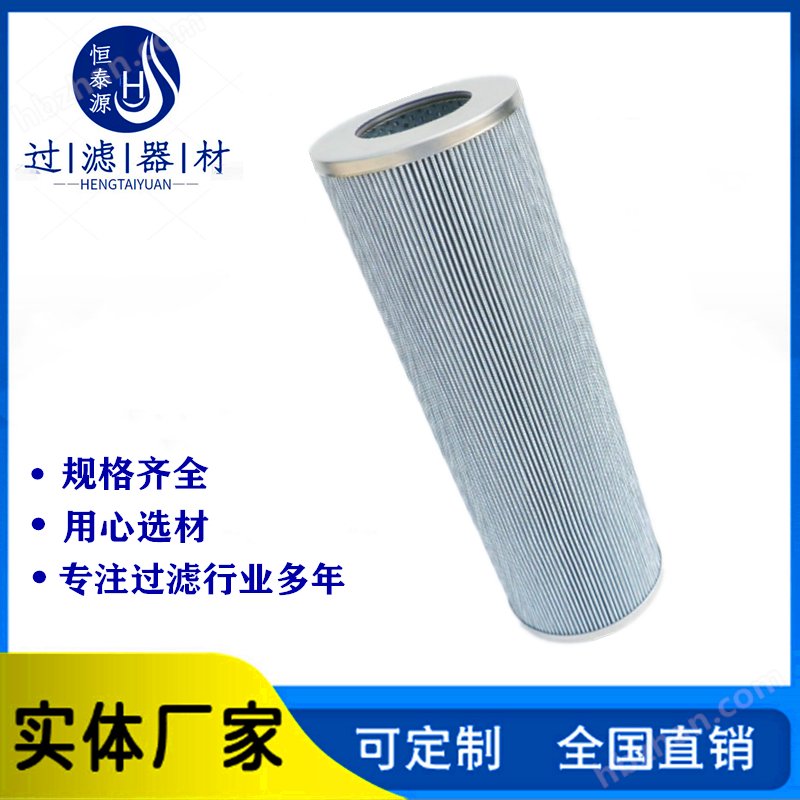

1. V3.0720-16 Hydraulic Lubrication Oil Circuit Filter ElementStructure and Characteristics

V3.0620-56 bending oil filter elementMaterial: Made of ultra-fine glass fiber cotton folded through a special process, forming a dense microporous structure.

Folding design: increases the filtering area (compared to flat filter cartridges), improves the pollutant holding capacity and flow rate, and extends the service life.

V3.0720-18 machine hydraulic oil filter elementFiltering accuracy: usually 0.1~100 microns, can intercept impurities such as particles, bacteria, colloids, etc.

2. V3.0833-03 Gear oil filter elementCore strengths

High retention rate:R928006374 filter hydraulic oil filter elementThe capture efficiency of small particles is high (such as over 99.5% for 0.3 micron particles).

High temperature resistance:Filter element for sludge treatment water equipmentCan withstand high temperatures above 200 ℃ (some models), suitable for high-temperature sterilization environments.

Low resistance:V3.0933-18 turbine oil station filter elementThe fiber structure is fluffy, maintaining a low pressure difference at high flow rates.

Chemical compatibility:V3.0510-08 Industrial Filter Oil GridAcid, alkali, and solvent resistance (to be confirmed according to specific models).

3. Lithium battery powder filter PE sintered filter cartridgeTypical Applications

Pharmaceutical industry: sterilization and filtration of injection solutions and biologics.

Food and beverage: clarification and filtration of alcoholic beverages and fruit juices.

Electronic industry:V2.0920-06 Hydraulic filter element for oil filterParticle control in the preparation of high-purity water.

Laboratory: solvent pre filtration, air particulate matter collection.

4. PE vacuum feeding machine filter elementKey parameters for selection

Aperture/precision: Select based on the particle size of pollutants (such as 0.22 μ m commonly used for sterilization).

High flow coalescence dehydration filter elementSize: The outer diameter/length should match the filter housing (commonly 10 inches, 20 inches, etc.).

Pressure resistance: working pressure range (usually ≤ 0.4MPa).