-

E-mail

1316831650@qq.com

-

Phone

17866760706

-

Address

No. 777, Xibian Village, Guoli Town, Huantai County, Zibo City, Shandong Province

Shandong Liangjian Environmental Protection New Materials Co., Ltd

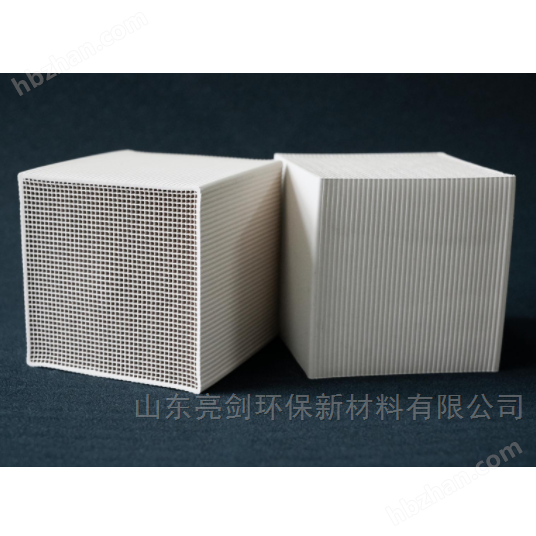

VOCs waste gas treatment using honeycomb zeolite

- Model

- Nature of the Manufacturer

- Producers

- Product Category

- Place of Origin

VOCs waste gas treatment using honeycomb zeolitePrepared from hydrophobic zeolites with different pore sizes, with a pore size ratio of about 60% and a specific surface area of 500-1000m3/g. Zeolite honeycomb structure has excellent organic waste gas adsorption performance and good gas permeability, especially suitable for high air volume and low concentration VOCS gas treatment.

The material itself is non flammable and can be safely used at an ambient temperature of 600C. It is a hydrophobic product

Has excellent desorption performance, can achieve desorption at around 180 ℃ -220 ℃, with short desorption time, clean desorption, and no secondary pollution

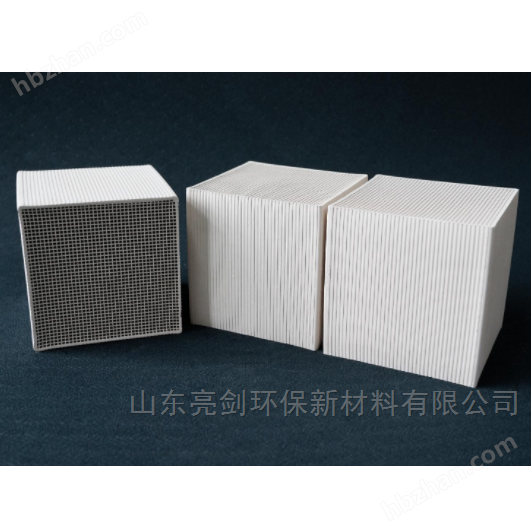

● It is a suitable material to replace honeycomb activated carbon, capable of high-temperature desorption and clean desorption, suitable for industries such as coating, printing, chemical, pharmaceutical, electronics, injection molding, petroleum, metallurgy, etc

Product size: can be customized according to customer needs

VOCs waste gas treatment using honeycomb zeoliteThe main material is natural zeolite. Zeolite manufacturers are inorganic microporous materials composed of SiO2, Al2O3, and alkaline metals or alkaline soil metals. Its pore volume accounts for 40-50% of the total volume, with a specific surface area of 100-500m2/g. It has the characteristics of high temperature resistance, non flammability, good thermal stability, and good hydrothermal stability. It is an efficient molecular sieve carrier with good adsorption performance and no secondary pollution. Compared with honeycomb activated carbon, its efficiency is about 25%, but it has the characteristics of high temperature resistance and not easy to ignite. Widely used in adsorption, separation, catalysis, environment and other fields, it is more suitable for the treatment of high air volume and low concentration organic waste gas.

The zeolite adsorbent product is: microporous adsorbent. Mesoporous adsorbent.

(1) Molecular sieves with a pore size less than 2nm are classified as microporous molecular sieves, while mesoporous molecular sieves have a pore size of 2-50nm (macroporous molecular sieves exceeding 50nm). Mesoporous molecular sieves have a high specific surface area, regular and ordered pore structure, narrow pore size distribution, and continuously adjustable pore size, playing an important role in separation catalytic reactions.

(2) Therefore, when selecting, molecular sieve materials with different properties and pore sizes should be configured according to the composition of different organic waste gases to meet design requirements and meet emission standards.