-

E-mail

2575369886@qq.com

-

Phone

13816887304,18616346166

-

Address

2nd Floor, Building 1, Lane 333, Wensong Road, Songjiang District, Shanghai

Shanghai Ouhe Machinery Equipment Co., Ltd

Vacuum sealed stirred emulsion reactor

- Model

- Nature of the Manufacturer

- Producers

- Product Category

- Place of Origin

Laboratory vacuum complete reactor

SE-20LVacuum sealed stirred emulsion reactor

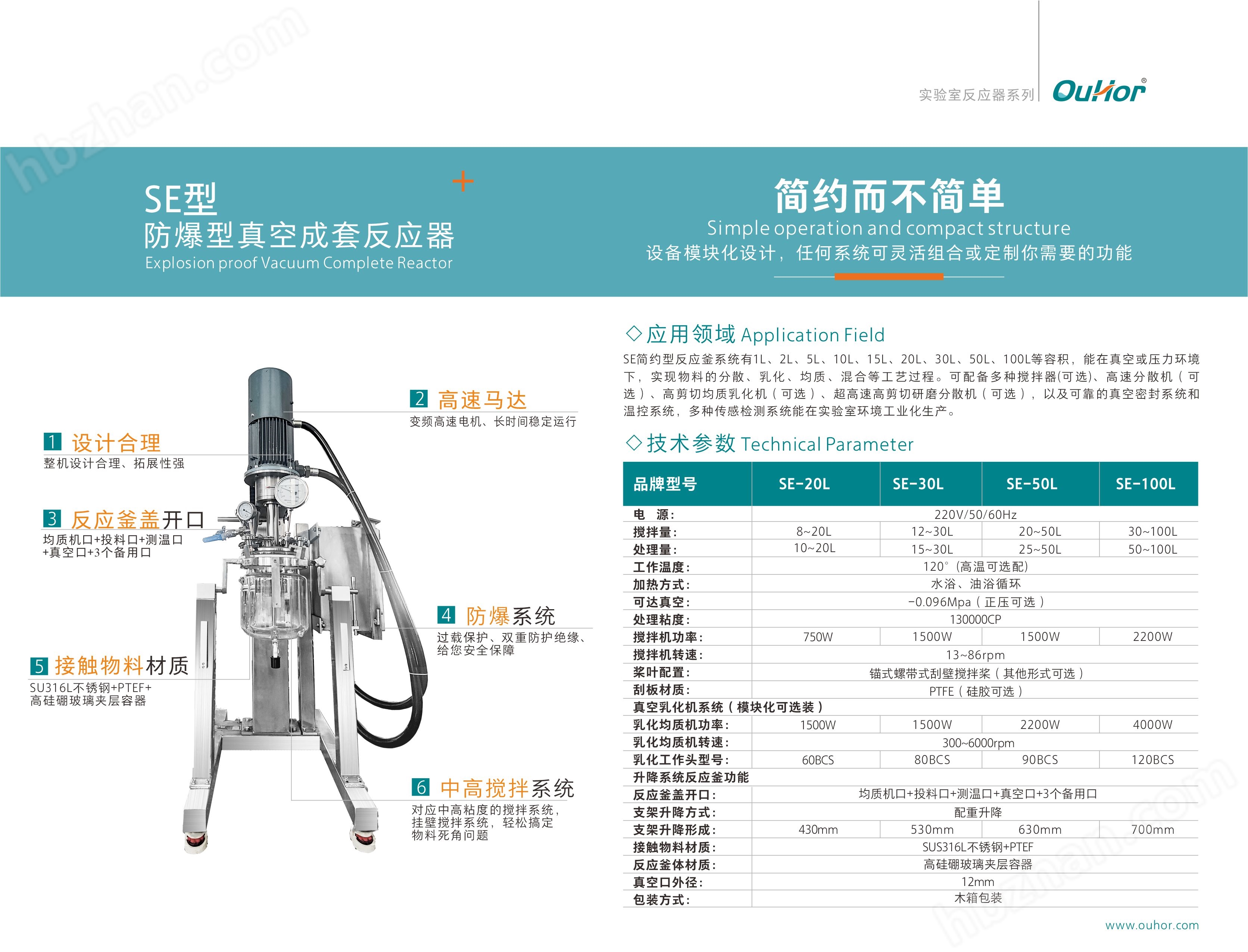

SE-20LSeries vacuum reactorApplication field

The SE minimalist reactor system has 1L、2L、5L、10LThe15LThe20LThe30L、50L、100LwaitvolumeIt can achieve processes such as dispersion, emulsification, homogenization, and mixing of materials in vacuum or pressure environments. Can be equipped with multiple mixers(Optional)、High speed disperser (optional)High shear homogenizer emulsifier(Optional)、Ultra high speed and high shear grinding and dispersing machine (optional),And reliable vacuum sealing system and temperature control system, multiple sensing and detection systems can be industrialized in laboratory environments.

SE-20LVacuum sealed stirred emulsion reactorFeatures and Advantages

At the bottomModular design of equipment, with optional installation of various typesmixsystem

At the bottomVariable frequency high-speed motor, stable operation for a long time

At the bottomThe overall structure design is reasonable,Strong scalability

At the bottomStepless speed regulation, the speed can reach up to6000rpm, For 27Shear line velocity of m/s

At the bottomMeet your different work environments (closed, open, normal pressure, vacuum)

At the bottomOverload protection, dual protection insulation, providing you with safety assurance

At the bottomThe working head is made of stainless steel material and can be reused,Modular design of equipmentAny system can be flexibly combined.Add any other customized features you need

SE-20LSeries vacuum reactorTechnical Specifications

Brand Model: |

SE-20L |

SE-30L |

SE-50L |

SE-100L |

electricity Source: |

220V/50/60Hz |

220V/50/60Hz |

220V/50/60Hz |

380V/50/60Hz |

Explosion-proof rating |

ExdIIBT4 |

ExdIIBT4 |

ExdIIBT4 |

ExdIIBT4 |

Mixing volume: |

8~20L |

12~30L |

20~50L |

30~100L |

Processing capacity: |

10~20L |

15~30L |

25~50L |

50~100L |

Operating Temperature |

120 ° (optional for high temperature) |

120 ° (optional for high temperature) |

120 ° (optional for high temperature) |

120 ° (optional for high temperature) |

Heating method: |

water bathOil bathcycle |

water bathOil bathcycle |

water bathOil bathcycle |

water bathOil bathcycle |

Can reach vacuum: |

-0.096Mpa (Positive pressure optional) |

-0.096Mpa (Positive pressure optional) |

-0.096Mpa (Positive pressure optional) |

-0.096Mpa (Positive pressure optional) |

Handling viscosity: |

130000CP |

130000CP |

130000CP |

130000CP |

Blender power: |

750W |

1500W |

1500W |

2200W |

Blender speed: |

13~86rpm |

13~86rpm |

13~86rpm |

13~86rpm |

Blade configuration: |

anchor typeribbon typeScraping wall stirring blade(Other forms are optional) |

anchor typeribbon typeScraping wall stirring blade(Other forms are optional) |

anchor typeribbon typeScraping wall stirring blade(Other forms are optional) |

anchor typeribbon typeScraping wall stirring blade(Other forms are optional) |

Scraper material: |

PTFE (silicone optional) |

PTFE (silicone optional) |

PTFE (silicone optional) |

PTFE (silicone optional) |

Vacuum emulsifier system(Modular optional) | ||||

Emulsifying homogenizer power: |

1500W |

1500W |

2200W |

4000W |

Emulsifying homogenizer speed: |

300~6000rpm |

300~6000rpm |

300~6000rpm |

300~3600rpm |

Emulsifying head model: |

60BCS |

80BCS |

90BCS |

120BCS |

Vacuum disperser system(Modular optional) | ||||

Disperser power: |

1500W |

1500W |

2200W |

4000W |

Disperser speed: |

Emulsifying homogenizer speed: |

300~6000rpm |

300~6000rpm |

300~6000rpm |

Dispersion disk specifications: |

60mm |

80mm |

90mm |

120mm |

Lift system reaction kettle function | ||||

Reactor lid opening: |

Homogenizer port+Feeding port+temperature measuring port+vacuum port+3 spare ports |

Homogenizer port+Feeding port+temperature measuring port+vacuum port+3 spare ports |

Homogenizer port+Feeding port+temperature measuring port+vacuum port+3 spare ports |

Homogenizer port+Feeding port+temperature measuring port+vacuum port+3 spare ports |

Bracket lifting method: |

Electric lifting |

Electric lifting |

Electric lifting |

Electric lifting |

Bracket lifting formation: |

430mm |

530mm |

630mm |

700mm |

Contact material material: |

SUS316L stainless steel+PTFE |

SUS316L stainless steel+PTFE |

SUS316L stainless steel+PTFE |

SUS316L stainless steel+PTFE |

Reactor body material: |

SUS316L stainless steel container Including interlayer and insulation layer |

SUS316L stainless steel container |

SUS316L stainless steel container |

SUS316L stainless steel container |

Vacuum portouter diameter: |

12mm |

12mm |

12mm |

12mm |

Mezzanine import、Export: |

Refer to the design drawing |

|||

outer packaging dimensions: |

Refer to the design drawing |

|||

weight: |

Refer to the design drawing |

|||

Packaging method: |

wooden case packaging |

|||

Optional configuration(Constant temperature sealed ultrasonic reactor)

At the bottomPH meter

At the bottomconductivity meter

At the bottomcondenser

At the bottomDrip tube

At the bottomSterile sampling valve