-

Phone

15906151243

-

Address

Gaocheng Town and Gaolu Fuchun Village, Yixing City

Product Categories

- Internal inflow membrane grille

- Rotary drum precision filter

- Micro filter series

- Scraping and suction mud machine series

- Online dilution device

- dosing system

- Anti pollution and decontamination series

- Sand water separator

- decanter

- Dosing device series

- Fiber disc filter

- Conveyor series

- Sand removal series of sedimentation tank

- Gate opening and closing machine series

- Air flotation series

- Filter press series

- Packing series

- Aerator series

Wuxi Houpu Environmental Protection Technology Co., Ltd

Variable microporous aerator

NegotiableUpdate on 01/18

- Model

- Nature of the Manufacturer

- Producers

- Product Category

- Place of Origin

Overview

Variable microporous aerator

Product Details

Product Introduction

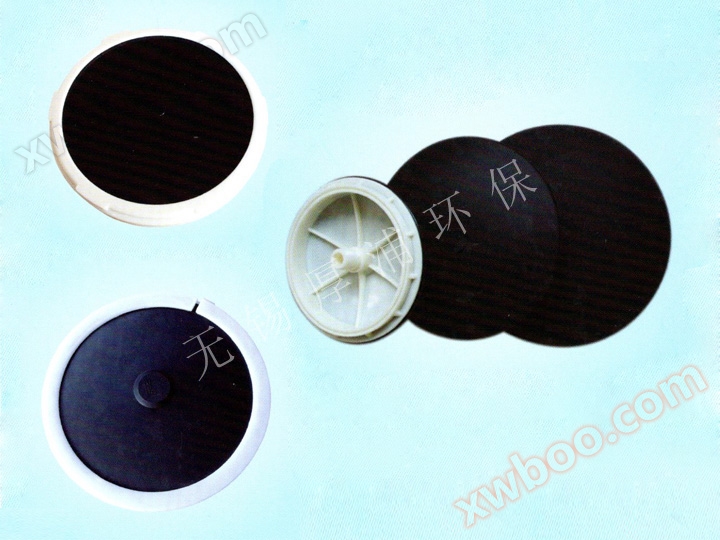

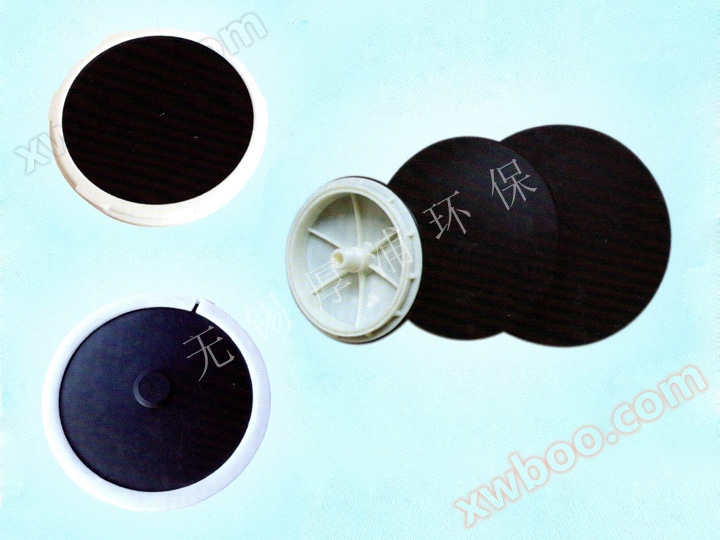

The variable microporous aerator is designed with a slightly raised arch surface and is mainly made of ABS engineering plastic. The membrane has a special imported rubber (EPDM) with an anti adhesion surface, which is made through special processing. The membrane holes are drilled with a CNC knife to ensure the quality and accuracy of the holes. The aerator is designed with four air supply slots on the main surface during oxygen aeration, allowing the incoming air to be buffered by a check valve and directly sent to the center of the aeration head, ensuring that the membrane can be easily opened with low resistance at once. The membrane adopts ribbed locking mechanical assembly to ensure that the membrane never falls off. During air intake, the micro pores on the air film expand and open on their own to ensure the passage of air. When the aeration is stopped, the variable micropores on the air distribution film are in a closed state. Due to the self expansion and contraction of the variable micropores on the air distribution film, the phenomenon of clogging of the aerator micropores is avoided. Secondly, a check valve device is installed on the bottom of the aerator to prevent the mixed liquid from entering the gas distribution branch pipe when the pipeline system stops supplying gas. This can prevent the mixed liquid from entering the branch pipe and being blocked. The incoming air does not require special filtration, intermittent aeration is not blocked, aeration is uniform, and oxygen transmission efficiency is high.

Product Features

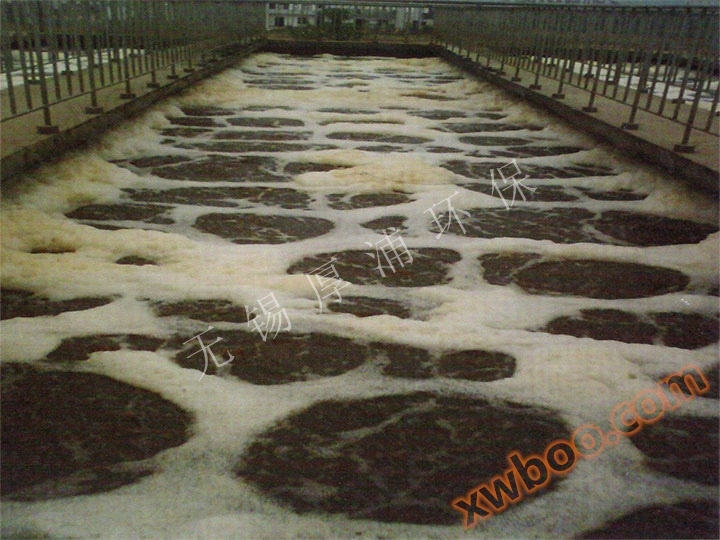

1. The gas diffusion rubber plate is made of synthetic rubber. The diameter of the bubbles diffused by the rubber membrane is small, the gas-liquid interface area is large, it has a high mass transfer rate, high oxygenation efficiency, can save electricity consumption, and reduce the operating cost of sewage treatment.

2. There are a large number of self closing holes on the rubber membrane, which can automatically open and close with oxygenation and shutdown, thus avoiding problems such as hole blockage and contamination. At the same time, the air entering the aerator does not need to be purified by dust removal. When the aeration tank stops running, the sewage mixture will not backflow, which can reduce a lot of operating costs and maintenance workload.

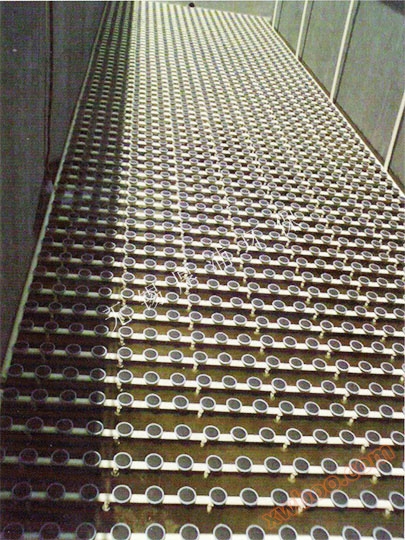

3. Due to the fact that the membrane type microporous aerator can be fully distributed at the bottom of the aeration tank, the dissolved oxygen in the tank is uniform, making it suitable for various tank types and depths. It can also be modified to improve the efficiency of the original aeration tank.

4. Due to the fact that the gas diffusion plate of the membrane type microporous aerator is made of rubber, it has good physical and mechanical properties. The tray, accessories, and air pipes are made of engineering plastics, which are not afraid of rust and reduce the workload of operation and maintenance.

5. The air pipeline adopts UPVC or ABS engineering plastic pipe (can be selected according to user needs), and the microporous aeration head is directly screwed onto the gas distribution pipeline, which is easy to install and use, and conducive to maintenance and repair.

Technical Parameter

The variable microporous aerator is designed with a slightly raised arch surface and is mainly made of ABS engineering plastic. The membrane has a special imported rubber (EPDM) with an anti adhesion surface, which is made through special processing. The membrane holes are drilled with a CNC knife to ensure the quality and accuracy of the holes. The aerator is designed with four air supply slots on the main surface during oxygen aeration, allowing the incoming air to be buffered by a check valve and directly sent to the center of the aeration head, ensuring that the membrane can be easily opened with low resistance at once. The membrane adopts ribbed locking mechanical assembly to ensure that the membrane never falls off. During air intake, the micro pores on the air film expand and open on their own to ensure the passage of air. When the aeration is stopped, the variable micropores on the air distribution film are in a closed state. Due to the self expansion and contraction of the variable micropores on the air distribution film, the phenomenon of clogging of the aerator micropores is avoided. Secondly, a check valve device is installed on the bottom of the aerator to prevent the mixed liquid from entering the gas distribution branch pipe when the pipeline system stops supplying gas. This can prevent the mixed liquid from entering the branch pipe and being blocked. The incoming air does not require special filtration, intermittent aeration is not blocked, aeration is uniform, and oxygen transmission efficiency is high.

Product Features

1. The gas diffusion rubber plate is made of synthetic rubber. The diameter of the bubbles diffused by the rubber membrane is small, the gas-liquid interface area is large, it has a high mass transfer rate, high oxygenation efficiency, can save electricity consumption, and reduce the operating cost of sewage treatment.

2. There are a large number of self closing holes on the rubber membrane, which can automatically open and close with oxygenation and shutdown, thus avoiding problems such as hole blockage and contamination. At the same time, the air entering the aerator does not need to be purified by dust removal. When the aeration tank stops running, the sewage mixture will not backflow, which can reduce a lot of operating costs and maintenance workload.

3. Due to the fact that the membrane type microporous aerator can be fully distributed at the bottom of the aeration tank, the dissolved oxygen in the tank is uniform, making it suitable for various tank types and depths. It can also be modified to improve the efficiency of the original aeration tank.

4. Due to the fact that the gas diffusion plate of the membrane type microporous aerator is made of rubber, it has good physical and mechanical properties. The tray, accessories, and air pipes are made of engineering plastics, which are not afraid of rust and reduce the workload of operation and maintenance.

5. The air pipeline adopts UPVC or ABS engineering plastic pipe (can be selected according to user needs), and the microporous aeration head is directly screwed onto the gas distribution pipeline, which is easy to install and use, and conducive to maintenance and repair.

Technical Parameter

| name | Φ215 | Φ260 | Φ300 |

| Work ventilation volume (m)3/h) | 1.5-3 | 2-5 | 2-8 |

| Design ventilation volume (m)3/h) | 2 | 2.5 | 4 |

| Service area (m)2) | 0.25-0.45 | 0.35-0.65 | 0.45-0.75 |

| Oxygen utilization rate (%) | >30 | >30 | >30 |

| Oxygenation capacity (kgO)2/h) | 0.13-0.35 | 0.18-0.45 | 0.25-0.5 |

| Submerged depth (m) | 4-8 | 4-8 | 4-8 |

| Theoretical power efficiency (kgO)2/kw.h) | 6.5 | 6.5 | 6.5 |

| Resistance loss (pa) | <3000 | <3000 | <3000 |