-

E-mail

zhuyanyiqi@163.com

-

Phone

18653195187

-

Address

No. 288 Wuyingshan Middle Road, Huaiyin District, Jinan City, Shandong Province

Product Categories

- Liquid leakage tester

- Glass bottle heat-resistant impact tester

- Thin film heat sealing strength tester

- Thin film friction coefficient tester

- Cone joint comprehensive performance tester

- Micro leakage sealing tester

- Glass bottle impact tester

- Medical packaging tearing force tester

- Ampoule breaking force tester

- Automatic Bottle Cap Torque Tester

- Glass bottle bottom thickness and wall thickness tester

- Glass Bottle Vertical Load Tester

Jinan Zhuyan Instrument Equipment Co., Ltd

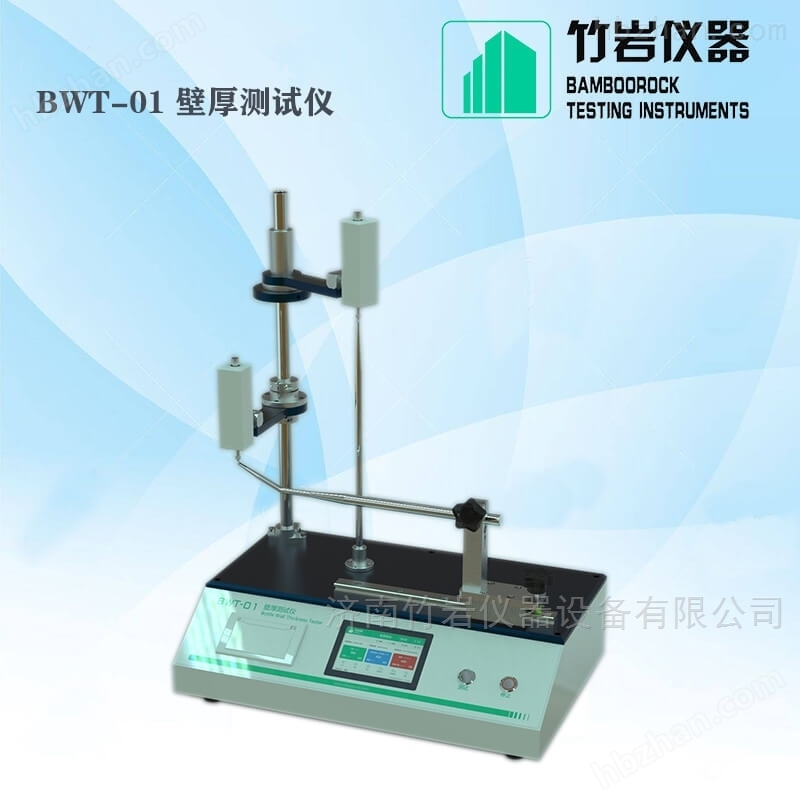

Wall thickness tester

NegotiableUpdate on 02/14

- Model

- Nature of the Manufacturer

- Producers

- Product Category

- Place of Origin

Overview

The working principle of the wall thickness tester is to measure the wall thickness of a medicinal glass bottle by contacting the probe with it. Before testing, place the tested medicinal glass bottle on the bracket and keep it horizontal. During the testing process, the probe will come into contact with the medicinal glass bottle and perform measurements. Record the position of the probe and the wall thickness of the measured glass bottle through a data acquisition system, and transmit the data to a computer for analysis and processing.

Product Details

In the pharmaceutical industry, glass bottles are commonly used packaging containers, and their quality and safety are highly concerned. The medicinal glass bottle thickness gauge is a key detection tool to ensure the uniformity and consistency of the bottle wall thickness.

Wall thickness testerThe working principle is to measure the wall thickness of a medicinal glass bottle by contacting it with a probe. Before testing, place the tested medicinal glass bottle on the bracket and keep it horizontal. During the testing process, the probe will come into contact with the medicinal glass bottle and perform measurements. Record the position of the probe and the wall thickness of the measured glass bottle through a data acquisition system, and transmit the data to a computer for analysis and processing.

The wall thickness tester has the following advantages:

1. High precision: By using high-precision measurement sensors and advanced software algorithms, the bottle wall thickness can be accurately measured.

2. Easy to operate: The thickness gauge is easy to operate and the staff can easily master, greatly improving the detection efficiency.

3. Safety of use: Non destructive testing will not cause damage to glass bottles, reducing testing costs and risks.

4. Efficient automation: The thickness gauge can automatically and quickly obtain bottle wall thickness data, reducing manual detection errors and labor intensity.

In summary, the medicinal glass bottle thickness gauge has broad application prospects and plays an important role in the pharmaceutical industry. Its high precision, easy operation, and safe automation make it a powerful assistant in the pharmaceutical industry. From production quality control, drug review to stability

In various aspects such as sexual research, thickness gauges have demonstrated their professionalism and necessity in the pharmaceutical industry. Therefore, the development and improvement of medicinal glass bottle thickness gauges are of great significance for improving the overall level of the pharmaceutical industry.

Wall thickness testerThe working principle is to measure the wall thickness of a medicinal glass bottle by contacting it with a probe. Before testing, place the tested medicinal glass bottle on the bracket and keep it horizontal. During the testing process, the probe will come into contact with the medicinal glass bottle and perform measurements. Record the position of the probe and the wall thickness of the measured glass bottle through a data acquisition system, and transmit the data to a computer for analysis and processing.

The wall thickness tester has the following advantages:

1. High precision: By using high-precision measurement sensors and advanced software algorithms, the bottle wall thickness can be accurately measured.

2. Easy to operate: The thickness gauge is easy to operate and the staff can easily master, greatly improving the detection efficiency.

3. Safety of use: Non destructive testing will not cause damage to glass bottles, reducing testing costs and risks.

4. Efficient automation: The thickness gauge can automatically and quickly obtain bottle wall thickness data, reducing manual detection errors and labor intensity.

In summary, the medicinal glass bottle thickness gauge has broad application prospects and plays an important role in the pharmaceutical industry. Its high precision, easy operation, and safe automation make it a powerful assistant in the pharmaceutical industry. From production quality control, drug review to stability

In various aspects such as sexual research, thickness gauges have demonstrated their professionalism and necessity in the pharmaceutical industry. Therefore, the development and improvement of medicinal glass bottle thickness gauges are of great significance for improving the overall level of the pharmaceutical industry.