-

E-mail

3830284546@qq.com

-

Phone

19106362018

-

Address

Oulong Technology Park, Jinma Road, High tech Zone, Weifang City, Shandong Province

Shandong Horde Electronic Technology Co., Ltd

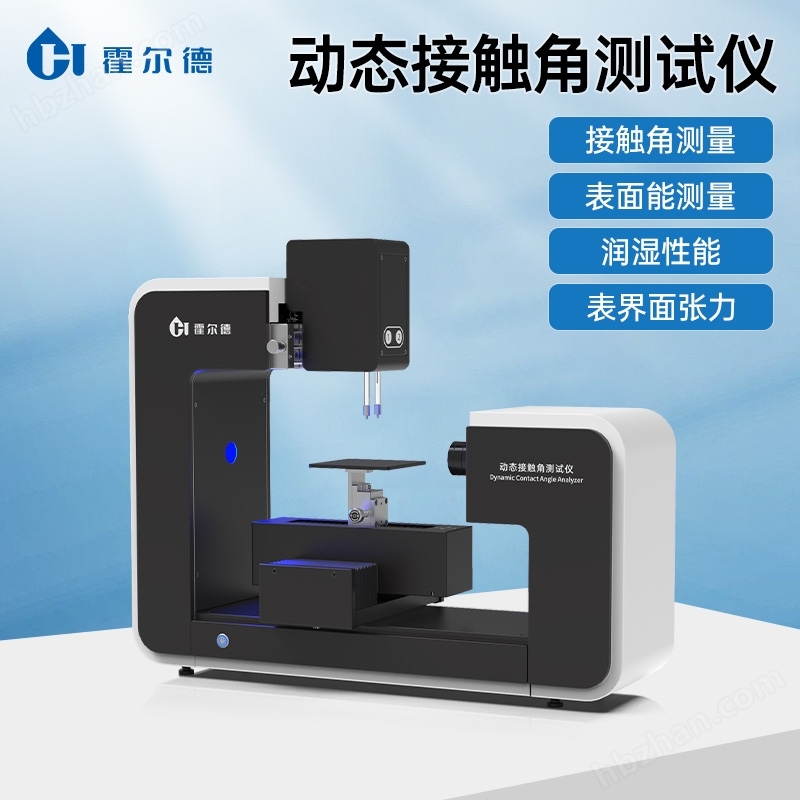

Water droplet angle measuring instrument

- Model

- Nature of the Manufacturer

- Producers

- Product Category

- Place of Origin

Water droplet angle measuring instrumentIt is a professional instrument for measuring the contact angle between liquids and solid materials, with the core purpose of characterizing the wetting performance of liquids on the surface of solid materials. Its workflow is to obtain droplet images through an optical imaging system, use computer software to fit the contour of the droplet image using mathematical models, and then obtain contact angle or surface tension data. Surface energy calculation and wettability analysis can be carried out to provide accurate basis for material surface performance evaluation.

Scope of application

Water droplet angle measuring instrumentWidely used in multiple industries, including mobile phone manufacturing, glass manufacturing, surface treatment, material research, chemical engineering, semiconductor manufacturing, coatings and inks, electronic circuits, textile fibers, medical biology, etc., it has become an important instrument for evaluating surface performance.

The specific testing and analysis functions that can be implemented are as follows:

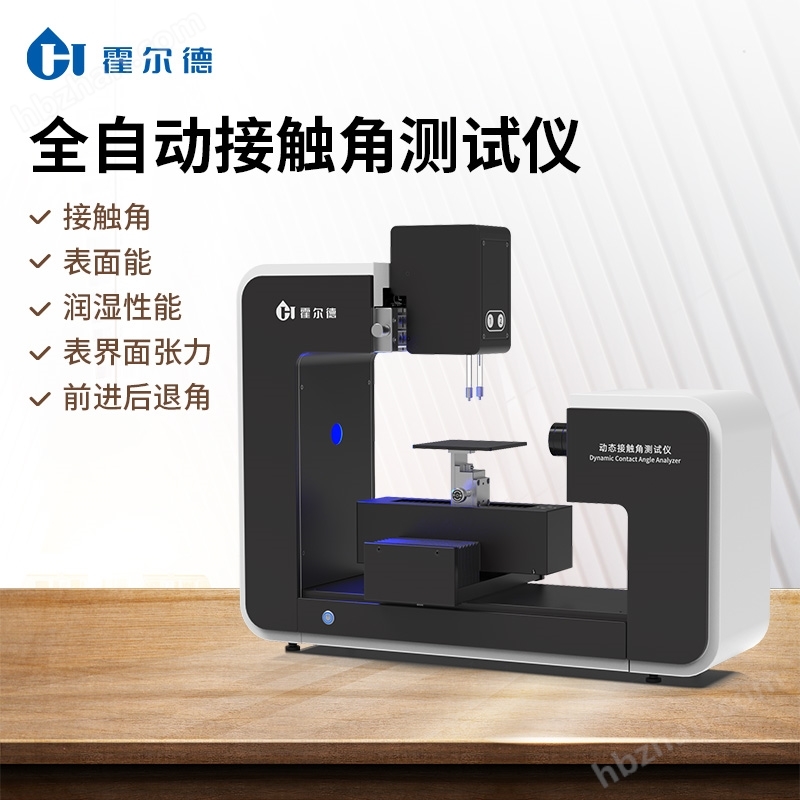

a. Analyze the wetting behavior of liquids on solid surfaces, such as spreading, permeation, and absorption, and measure the static contact angle using the seat drop method;

b. Measure the advance angle, retreat angle, contact angle hysteresis, rolling angle, and dynamic contact angle of materials on solid surfaces;

c. Conduct continuous real-time research on absorbent materials and record the process, generate contact angle variation curves over time, and conduct analysis;

d. Measurement of contact angle for special materials such as powders, curved surfaces, superhydrophobic/superhydrophilic samples, etc;

e. Using the attachment droplet method to test the contact angle of materials immersed in liquid;

f. Using the suspended droplet method to measure the interfacial tension, polarity, and dispersion components of various liquids;

g. Calculate the surface free energy of the solid and analyze its polar dispersion component;

h. Analyze the adhesion work of liquids on solid surfaces and evaluate the uniformity and cleanliness of solid surfaces.

(Note: Some testing functions require the purchase of specialized accessories to be completed)

Reference standards (partial standards)

JJF2099-2024 Calibration Specification for Optical Contact Angle Measuring Instrument;

GB/T30693-2014 Measurement of Contact Angle between Plastic Film and Water;

GB/T30447-2013 Measurement method for contact angle of nano thin films;

GB/T42694-2023 Testing and evaluation of surface wetting resistance of textiles - Contact angle and rolling angle method;

ASTMD724-1999 (2003) Standard Test Method for Surface Wettability of Paper (Contact Angle Method);

GB/T24368-2009 Detection of hydrophobic contaminants on glass surfaces;

SY/T5153-2007 Determination Method for Wettability of Reservoir Rocks;

ASTMD5946-2004 Measurement of Contact Angle between Plastic Film and Water;

ISO15989 Measurement of water contact angle for plastic film and thin plate corona treated film

Product Features

1. * Auxiliary focusing system: equipped with high-sensitivity auxiliary focusing function, ensuring clear imaging, convenient operation, and effectively improving measurement accuracy and efficiency.

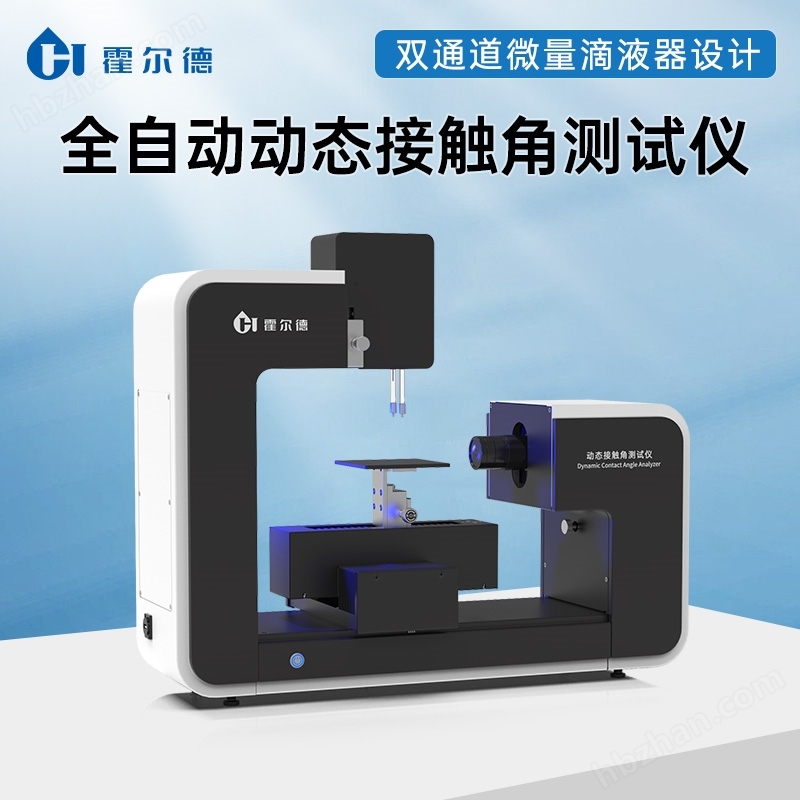

2. Dual channel microdroplet design: Adopting a dual channel microdroplet system, it can adapt to various detection environments, significantly improving detection efficiency and flexibility.

3. Visual camera angle adjustment: The camera shooting angle supports precise visual adjustment, which can adapt to complex sample morphology and special experimental scenes, enhancing system versatility.

4. Fully automatic micro dropper cleaning system: The dropper channel has a fully automatic cleaning function, which can prevent cross contamination and ensure the accuracy and repeatability of detection results.

5. Continuous and batch automatic dripping function: By starting the process of automatic dripping, receiving, measuring, and changing points with one click, efficient and equidistant batch sample testing can be achieved, significantly improving detection efficiency and reducing human errors, ensuring stable and reliable data.

6. Sample stage: Equipped with a three-dimensional automatic displacement device and fully software controlled, it achieves automatic fixed-point positioning measurement and can set different testing plans according to different products.

7. Injection unit: High precision injection pump is used for liquid injection, which is controlled by software for quantitative and speed control. The droplet is stable and the accuracy is very high.

8. High precision transmission and positioning system: using a precision transmission mechanism to achieve high-precision positioning and repetitive positioning control, it can achieve precise fixed-point measurement at the microscale.

9. High strength and stable structural design: The internal framework of the equipment adopts high-strength and high stability aviation aluminum structure, greatly improving the mechanical stability and anti-interference ability of the system, ensuring scientific research grade accuracy under long-term operation.

10. High precision multifunctional analysis module and intelligent algorithm: Built in multi-mode measurement method, supporting contact angle, wetting performance, surface tension, surface energy, forward and backward angle and hysteresis angle, multi-point automatic intelligent contact angle measurement, etc., to meet the multi scenario testing needs of different materials and liquid systems, and provide comprehensive interface characteristic evaluation.

11. High definition imaging system: using LED cold light source, USB high-definition industrial camera, and continuous zoom telephoto lens to achieve high-resolution and low distortion droplet imaging.

12. Multi scene video recording function: supports video capture and playback during the testing process, and can be used for dynamic contact angle analysis and experimental teaching.

13. Adjustable viewing angle: Supports multiple viewing angles such as head up, top-down, and bottom-up to meet the needs of different testing scenarios.

14. Automatic fitting method for contact angle measurement and analysis software: supports one click automatic fitting without manual error. Fitting methods include Circle method, Ellipse/Oblique ellipse, etc.

15. Sample scheme setting, saving, and retrieval: The measurement scheme can be set in the software according to the actual sample size specifications, and subsequent testing of similar products can directly retrieve the stored scheme to carry out work; The measurement schemes set for different samples can be saved, and can be directly retrieved for the next measurement of the same type of sample, improving testing efficiency.

16. Bilateral contact angle measurement: With the fast fitting function of bilateral contact angle measurement, it can comprehensively analyze the surface wetting performance of liquids and solids, and more accurately reflect the actual wetting situation of the surface.

17. Dynamic data recording and fitting: supports dynamic shooting and rapid testing of video data, can continuously record changes in test contact angle, and then automatically fit in batches by software to obtain dynamic change patterns.

18. Multi format report generation: The software can automatically generate reports, covering various data reports such as PDF format, Excel format, spectrum format, etc., to meet the data presentation needs in different scenarios.

19. Customized functional support: With a variety of optional functional components, the company's R&D team has strong capabilities and can meet various customized measurement requirements proposed by customers.

Technical Specifications

| Overall dimensions | 715mm (length) × 220mm (width) × 590mm (height) | |

| host weight | 23kg | |

| Whole machine adjustment | Whole machine level testing/adjustment | |

| Carrier size | 120mm×120mm | |

| Stage adjustment | Three dimensional adjustment, left and right 85mm x front and back 120mm x up and down 35mm; left and right, front and back are automatic movements, up and down are manual movements, with a movement accuracy of ± 0.05mm; | |

| The most Large image | 2592×1944 | |

| The most high frame rate | 30fps | |

| transmission | USB 2.0 | |

| focal length | 116+3mm | |

| Lens magnification | 0.6~4.5 times | |

| light source | LED cold light source, 470nm | |

| power supply | 220V | |

| drip | Software controlled automatic liquid inlet; Dropping accuracy: ± 0.01 μ L; Minimum droplet volume: 0.05 μ L/droplet (customized sampler required); | |

| syringe | Glass microsampler, capacity 500 μ L | |

| needle | 0.5mm and 0.9mm all stainless steel needles | |

| contact angle | measurement range | 0~180° |

| precision | ±0.1° | |

| measurement method | Automatic measurement, manual measurement, dynamic measurement | |

| Fitting method | Width height method, circle fitting method, ellipse fitting method, polynomial fitting method, Young Laplace fitting method, ADSA-NA fitting method | |

| surface tension | measurement range | 0.01~2000mN/m |

| resolution | 0.001mN/m | |

| measurement method | Suspension Drop Method (Young Laplace Fitting Method) | |

| Surface energy measurement method | Fowkes、OWRK、Wu、Zisman、EOS | |

| Wettability analysis | Adhesion work, wetting work, spreading coefficient | |

| Forward and backward angle measurement | Measure the forward and backward angles of the material surface and analyze the phenomenon of contact angle hysteresis. | |