-

E-mail

970805072@qq.com

-

Phone

15838053733

-

Address

No. 99, Jingsan Road North, Jinshui District, Zhengzhou City

Zhengzhou Jiutai Technology Co., Ltd

Wind turbine blade crawling detection robot

- Model

- Nature of the Manufacturer

- Producers

- Product Category

- Place of Origin

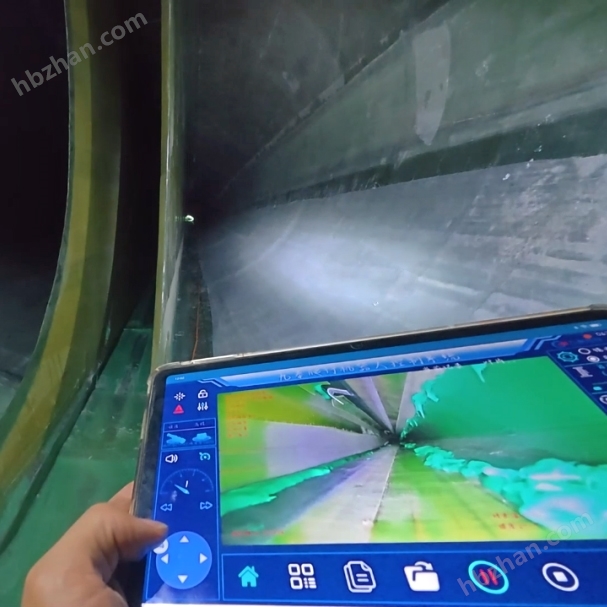

Wind turbine blade crawling detection robotAdopting a portable tablet control terminal, assisting with powerful lighting sources and meter cable devices, coupled with a small electric pay off cart, it is lightweight, portable, and automatically retracts and retracts cables. Enter the working condition and perform operations such as video recording, defect capture, and recording defect location information. 5 million front and rear dual view images, real-time transmission of endoscopic images, equipped with 10x zoom and macro focusing technology, automatic/manual focusing achieves the best video effect through precise zoom focusing. Adopting modular design, 6-wheel drive, with a climbing angle of up to 45 degrees and a built-in tilt angle sensor, real-time communication of the vehicle's status during movement. The whole machine has the characteristics of small size, flexible and lightweight, and adjustable crawling speed, and is widely used in various concealed and limited spaces for real-time internal image detection operations. Built in defect detection software, and real-time generation of inspection report files for detailed analysis of internal inspection data under working conditions, with support for online editing. When the robot burrows into the "belly" of the blade, it is not only searching for cracks and debonding, but also exploring a safer, more efficient, and more sustainable path of new energy.

Wind turbine blade crawling detection robotIt is possible to enter the narrow space inside the blade and perform endoscopic inspection on defects such as bulges, wrinkles, delamination, and cracks inside the blade. Easy access to locations that cannot be reached during manual inspections, completing fast, comprehensive, and efficient internal inspection work. Its advantage lies in the internal observation of fan blades, which can avoid the influence of blade paint surface, identify defects more timely and accurately, reduce losses and maintenance costs, and improve the operational efficiency and inspection quality of fan internal inspection. By combining intelligent external inspection and maintenance solutions for wind turbine blades, and further integrating blade defect data, it is possible to achieve full lifecycle management of the defect dimension of wind turbine blades, thereby supporting refined operation and maintenance planning and the development of predictive maintenance strategies.

In summary, the core task of the wind turbine blade endoscopic robot is to conduct a comprehensive "physical examination" of the "invisible" structural health status inside the blade, focusing on the defects (delamination, wrinkles) of the composite laminate itself, the bonding quality between key structural components (debonding), the state of the core material (core material), and various damages generated during manufacturing and operation. The purpose is to detect potential problems early, evaluate the structural integrity of the blades, provide a basis for maintenance decisions, prevent catastrophic failures, ensure the safe operation of the wind turbine, and extend the service life of the blades.