-

Phone

13861505118

-

Address

No. 20 Chengwen Road, Gaocheng Town, Yixing City

Jiangsu Youke Environmental Protection Technology Co., Ltd

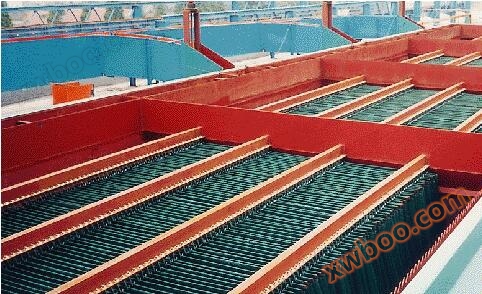

ZX combination high-efficiency inclined plate (tube) sedimentation tank

- Model

- Nature of the Manufacturer

- Producers

- Product Category

- Place of Origin

The inclined tube sedimentation tank refers to a sedimentation tank with inclined tubes installed in the sedimentation area. There are two types of assembly forms: inclined pipes and branch pipes. Using inclined parallel sedimentation in the sedimentation zone of a horizontal or vertical sedimentation tank

The pipe or parallel pipeline (sometimes using honeycomb packing) is divided into a series of shallow sediment layers, and the treated and settled sediment moves and separates from each other in the shallow sediment layers. According to their mutual motion directions, they can be divided into three different separation methods: reverse (opposite) flow, same direction flow, and lateral flow. Every two parallel inclined plates (or inside parallel pipes) is equivalent to a very shallow sedimentation tank.

Its advantages are:

① By utilizing the principle of laminar flow, the processing capacity of the sedimentation tank has been improved;

② Shortened the settling distance of particles, thereby shortening the settling time;

③ The sedimentation area of the sedimentation tank has been increased, thereby improving the treatment efficiency.

The flow rate of this type of sedimentation tank can reach 36m3/(m2 · h), which is 7-10 times higher than the processing capacity of general sedimentation tanks. It is a new and efficient sedimentation equipment. And it has been finalized for production practice.

Advantages: High removal rate, short residence time, and small footprint. Principles of Shallow Pool Theory

Assuming the length of the inclined tube sedimentation tank is L, the horizontal flow velocity in the tank is V, and the particle settling velocity is u0, under ideal conditions, L/H=V/ u0。 When the values of L and V remain constant, the shallower the pool depth H, the smaller the suspended particles that can be removed. If a horizontal partition is used to divide H into 3 layers, with each layer having a depth of H/3, under the condition of constant u0 and v, only L/3 is needed to remove the particles of u0. That is to say, the total volume can be reduced to one-third of its original size. If the pool length remains unchanged and the pool depth is H/3, the horizontal flow velocity can be increased to 3V, which can still remove particles with a settling velocity of u0, thus increasing the processing capacity by three times. Simultaneously dividing the sedimentation tank into n layers can increase the processing capacity by n times. This is the shallow pool theory proposed by Hazen in the early 20th century.

Design parameters

(1) The spacing between inclined plates (pipes) is generally not less than 50mm, and the length of inclined plates (pipes) is generally around 1.0-1.2m;

(2) The upper layer of the inclined plate should have a water depth of 0.5-1.0m, and the height of the bottom buffer layer should be 1.0m. The lower part of the inclined plate (pipe) is the wastewater distribution area, generally not less than 0.5m in height, and the lower part of the water distribution area is the sludge area;

(3) Multiple rows of perforated pipes are generally used to collect water from the pool, and the holes should be 2cm below the water surface to prevent floating objects from being carried away;

(4) The flow rate of wastewater in the inclined pipe depends on different types of wastewater, such as treating domestic sewage, with a flow rate of 0.5-0.7mm/s.

(5) The inclined plate (pipe) forms a 60 ° angle with the horizontal plane, and the clear distance between the inclined plate (or inclined pipe aperture) is generally 80-100mm.

The design calculation formula for the sedimentation tank with inclined plates (pipes) for opposite flow can be obtained by the following analysis.

Assuming there is a counter current sedimentation unit with an inclination angle of a, a length of l, a cross-sectional height of d, a width of w, an average water flow velocity v within the unit, and a sedimentation velocity of u0 for the particles removed