-

E-mail

gfhr@infore.com

-

Phone

13333333333

- Address

Zhejiang Shangfeng High tech Specialized Wind Industry Co., Ltd

smoke exhaust fire damper

- Model

- Nature of the Manufacturer

- Producers

- Product Category

- Place of Origin

Technical functions and main materials

product |

PFHF smoke exhaust fire damper |

|

institution |

Valve body, blades, actuator, temperature sensor and other components |

|

skillSurgical indicators |

Normally Open |

|

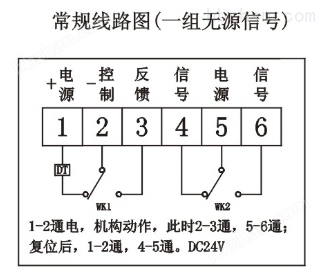

Input DC24 close signal, the valve closes; Output feedback signal for close in position | ||

280 ℃ temperature sensor melts and closes valve | ||

Manual reset | ||

The actuator is installed on the main body | ||

Main component materials |

valve body |

High quality galvanized steel sheet/thickness 1.8mm |

blade |

High quality galvanized steel sheet/thickness 1.8mm |

|

rotating shaft |

SUS304/φ12 |

|

bushing |

SUS304 |

|

Valve thickness |

Valve thickness: 205mm |

|

flange |

Flange edge width: 32mm |

|

Note: In order to maintain consistency with the customer's installation dimensions, if not specified by the customer, the flange will not be perforated

Overall dimensions

rectangle

rotundity

Valve specifications and dimensions

serial number |

B |

A |

|||||||||||

160 |

200 |

250 |

320 |

400 |

500 |

630 |

800 |

1000 |

1250 |

1600 |

2000 |

||

1 |

160 |

√ |

√ |

√ |

|

|

|

|

|

|

|

|

|

2 |

200 |

|

√ |

√ |

√ |

√ |

√ |

|

|

|

|

|

|

3 |

250 |

|

|

√ |

√ |

√ |

√ |

√ |

√ |

|

|

|

|

4 |

320 |

|

|

|

√ |

√ |

√ |

√ |

√ |

|

|

|

|

5 |

400 |

|

|

|

|

√ |

√ |

√ |

√ |

√ |

|

|

|

6 |

500 |

|

|

|

|

|

√ |

√ |

√ |

√ |

√ |

√▲ |

|

7 |

630 |

|

|

|

|

|

|

√ |

√ |

√ |

√ |

√▲ |

|

8 |

800 |

|

|

|

|

|

|

|

√ |

√ |

√ |

√▲ |

√▲ |

9 |

1000 |

|

|

|

|

|

|

|

|

|

|

√▲ |

√▲ |

10 |

1250 |

|

|

|

|

|

|

|

|

|

|

√▲ |

√▲ |