-

E-mail

hzhuf@163.com

-

Phone

13503187732

-

Address

Hongwuzhuang Village, Zaoqiang County, Hebei Province

Zaoqiang Runhe Environmental Protection Equipment Co., Ltd

The treatment and purification of acid mist waste gas in the alkali spray tower utilizes the "acid-base neutralization reaction" to combine H ⁺ in the waste gas with OH ⁻ in the alkali solution to generate salt and water, achieving acid mist purification. The types of acid mist it is compatible with include HCl, H ₂ SO ₄, HNO ∝ HF、 Acetic acid is widely used in industries such as chemical engineering, electroplating, acid washing, semiconductor manufacturing, metallurgy, etc.

Combination process for treating and purifying acid mist waste gas in alkali spray tower:

1. Conventional acid mist (dust-free): "Alkali spray tower+wire mesh demister+activated carbon adsorption bed"

Function: Spray tower for treating acid mist above 95%, demister for treating water mist, activated carbon adsorption bed for adsorbing residual trace acid mist and odors

2. Acid mist containing dust (such as acid washing and sandblasting waste gas): "Cyclone dust collector+alkali spray tower+demister"

Function: The cyclone dust collector first processes dust of ≥ 10 μ m, avoiding the formation of mud blocking the packing layer when dust mixes with alkali solution, and improving the stability of the spray tower operation.

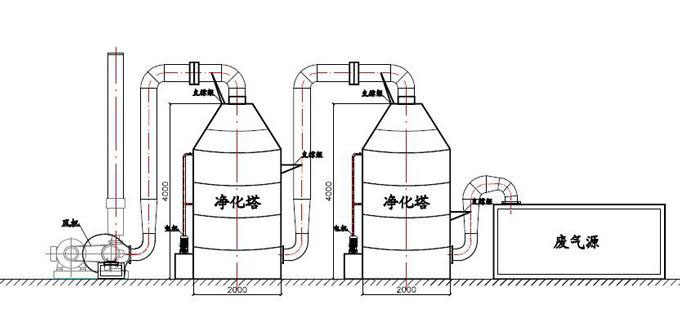

3. High concentration acid mist (≥ 500mg/m ³): "Two stage alkali spray tower in series+demister"

The high concentration alkali solution (5-8) of spray tower 1 is initially neutralized, while the low concentration alkali solution (2-3) is used for purification in spray tower 2, with an outlet concentration of ≤ 10mg/m ³.

Daily maintenance of acid mist exhaust gas treatment and purification in alkali spray tower:

| maintenance project | maintenance cycle | Maintenance content |

| PH/liquid level monitoring | real-time monitoring | Ensure the pH is between 8.5-10.5 and replenish water promptly when the liquid level is below the lower limit |

| Spray head cleaning | Once a week (manually)+daily automatic backwashing | Dismantle the sprinkler head and clean the salt crystals and impurities inside the aperture |

| Packing layer cleaning | Once a month | Remove the packing, rinse the surface sediment with clean water, and replace the damaged packing |

| Mist remover flushing | Once every 8 hours (automatic) | Rinse the surface of the demister with circulating water to avoid blockage caused by acid mist crystallization |

| Cleaning of circulating water tank | Once a week | Clean up salt deposits and impurities in the sedimentation area |

| FRP tower body inspection | Once every quarter | Check whether there is corrosion or damage on the inner wall of the tower, and whether the flange interface leaks |