-

E-mail

hzhuf@163.com

-

Phone

13503187732

-

Address

Hongwuzhuang Village, Zaoqiang County, Hebei Province

Zaoqiang Runhe Environmental Protection Equipment Co., Ltd

Waste gas treatment of alkaline spray tower electroplating process

Date: 2025-12-10Read: 12

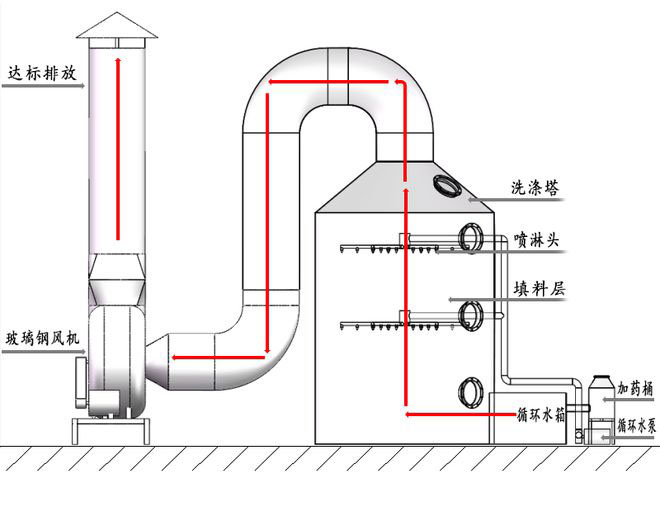

The electroplating process generates various waste gases during acid washing, passivation, and other processes. The alkaline spray tower converts acidic waste gases into salts (such as NaCl and Na ₂ SO ₄) through acid-base neutralization chemical reactions, while achieving cooling and defogging, laying a foundation for subsequent treatments (such as activated carbon adsorption and RTO).

Structural Design of Alkali Spray Tower Body

| component | Selection Requirements (Customization of Electroplating Scenarios) | Function and advantages |

| Main body of the tower | Diameter of 800-1500mm (single tower), wall thickness ≥ 12mm, flange thickened to 18mm | Adapt to low airflow, ensure structural strength, and prevent negative pressure deformation |

| Packing layer | FRP stepped ring (φ 38 × 38 × 1.2mm) or PP multi-faceted hollow sphere, with a layer height of 1.2-1.8m | Specific surface area ≥ 180m ²/m ³, enhanced gas-liquid contact, acid and alkali corrosion resistance |

| sprinkler system | 2-layer FRP spiral nozzle (spray angle 120 °, aperture 1.5-2mm), nozzle spacing 300-400mm | Avoid clogging the nozzle with viscous impurities in electroplating waste gas to ensure even spraying |

| Defogging layer | FRP baffle defogger (equipped with PTFE wire mesh), defogging efficiency ≥ 98% | Treat alkali mist and heavy metal salt mist in exhaust gas to prevent pollution of subsequent equipment |

| Circulating liquid tank | Volume ≥ 5-minute flow rate of circulating pump, lined with FRP anti-corrosion layer, equipped with liquid level gauge and drain outlet | Store alkaline solution for regular discharge and removal of heavy metal precipitates (such as Cu (OH))₂、Ni (OH)₂) |

Technical parameters for waste gas treatment in alkaline spray tower electroplating process

| parameter | design value | Electroplating scene description |

| Empty tower gas velocity | 0.8-1.2m/s | Lower than conventional industrial waste gas (1.2-1.5m/s) |

| liquid-to-gas ratio | 8-12L/m³ | Higher than normal operating conditions |

| Alkali concentration | NaOH,NaOH,NaClO | |

| Gas liquid contact time | ≥3s | Ensure the reaction time of HCN and other waste gases |

| Circulating pump power | 3-5.5kW | Choose fluoroplastic pump to avoid pump body leakage |

| Tower resistance | 800-1200Pa | The supporting fan should be of anti-corrosion and explosion-proof type |