-

E-mail

hzhuf@163.com

-

Phone

13503187732

-

Address

Hongwuzhuang Village, Zaoqiang County, Hebei Province

Zaoqiang Runhe Environmental Protection Equipment Co., Ltd

The ridge type defogger is a type of baffle type defogger equipment, named after its herringbone/ridge shape, and is the main component of wet flue gas desulfurization systems.

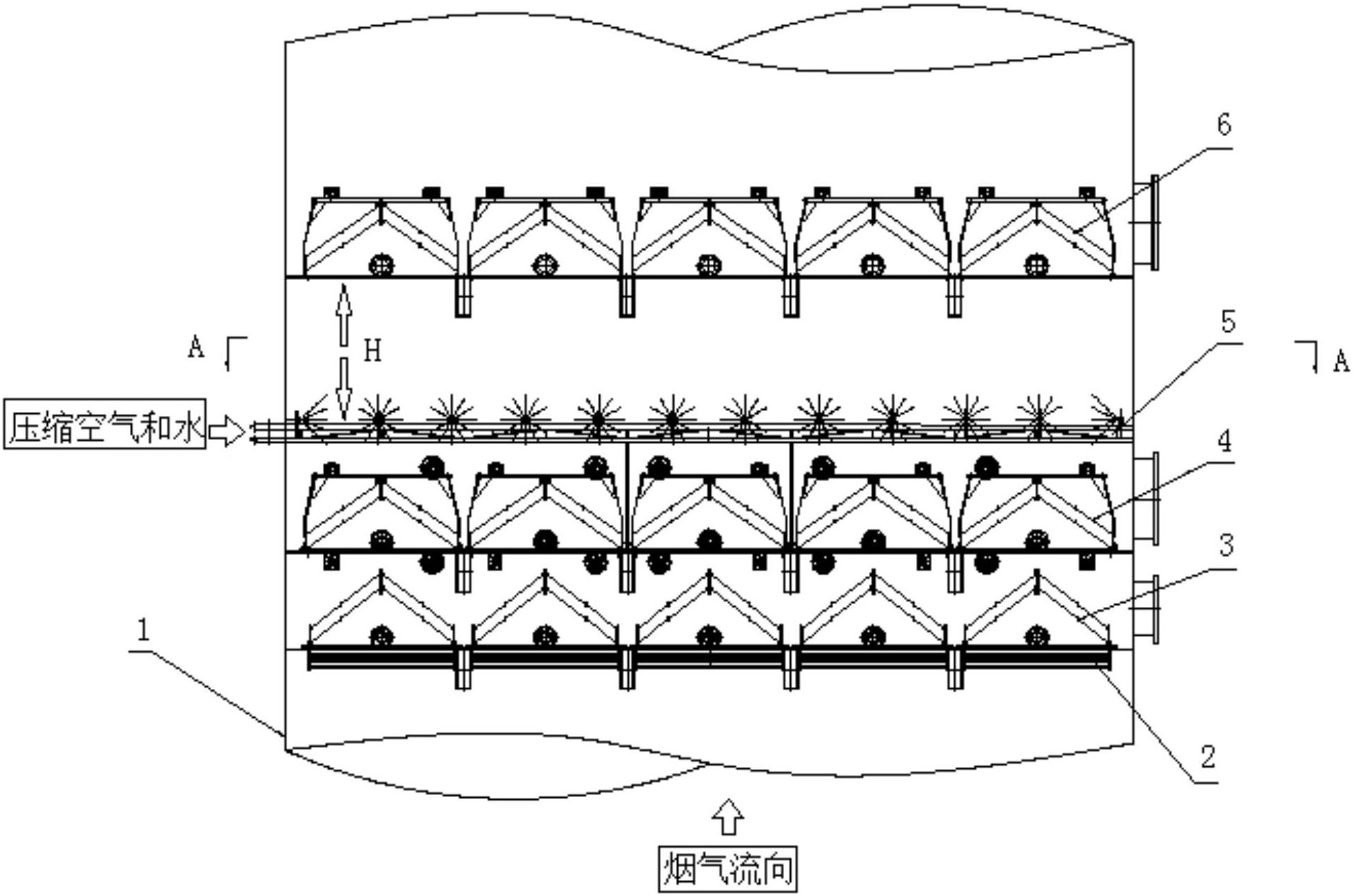

Roof type defogger structure:

Main body: composed of two (or more) levels of herringbone shaped leaves, forming a 'V' - shaped channel

Blade: sine wave type, single hook type, hole hook type, etc., commonly made of PP/fiberglass material, thickness 2.7-3.0mm

Support system: single-layer beam support to ensure stability

Flushing system: 3-4 layers of flushing water pipes and nozzles, with a coverage rate of 150%, to prevent scaling

屋脊式除雾器原理:

Mechanism: Inertial collision+centrifugal separation+gravitational settling

Airflow diversion: Misty smoke is redirected multiple times when passing through curved channels

Droplet separation: Mist droplets maintain their original trajectory due to inertia and collide with the blade surface to form a liquid film

Liquid film collection: The liquid film flows along the blades to the bottom and returns to the absorption tower

Smoke: After purification, the smoke is discharged from above the defogger

Selection and design points of ridge type defogger:

1. Flow rate control

Range: 2.8-4.5m/s

<2.5m/s: Insufficient droplet inertia, efficiency drops sharply

>5.0m/s: Captured droplets are rewound ('secondary water carrying'), resulting in a significant increase in pressure drop

2. Leaf selection

Primary: spacing 25-35mm, handling large droplets over 10 μ m

Secondary: spacing 15-25mm, handling 5-10 μ m small droplets

3. Material selection

PP: ≤ 80 ℃, high cost-effectiveness

FRP/PPH: 80-120 ℃, strong corrosion resistance

4. Flushing system design

Pressure: 0.2-0.4MPa, ensuring clean flushing without damaging the blades

Frequency: Regular once per hour, 30-60 seconds each time

Nozzle: fan-shaped (120 ° coverage), ensuring no blind spots for flushing

Last Article: Introduction to integrated biological deodorization tower

Next Article: Introduction to Wet Cyclone Dust Collector