-

E-mail

hzhuf@163.com

-

Phone

13503187732

-

Address

Hongwuzhuang Village, Zaoqiang County, Hebei Province

Zaoqiang Runhe Environmental Protection Equipment Co., Ltd

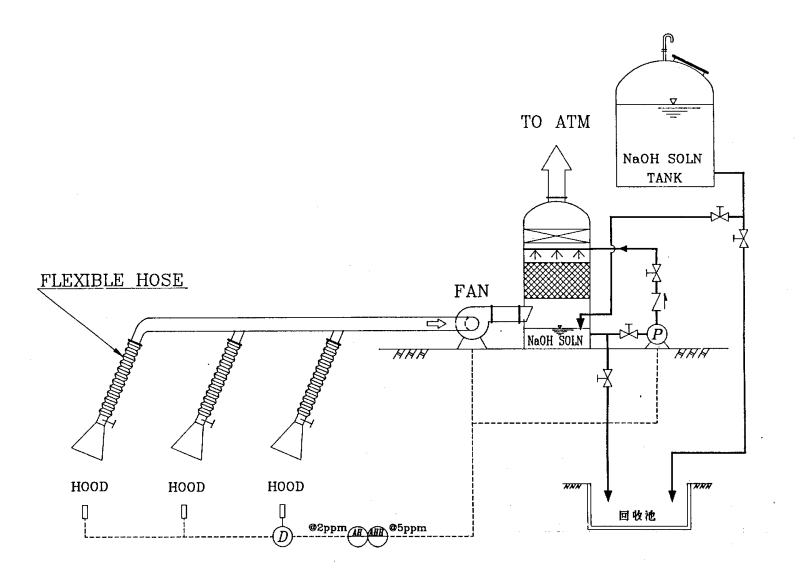

Design of plant liquid spray tower for treating sludge, temporary storage of sludge, and mixing process for waste gas treatment:

(1) Sludge temporary storage process (low dust, medium low concentration odor)

Sealed collection in temporary storage room → gas collection hood → air duct → plant liquid spray tower → fan → standard discharge

No pre-treatment required: The temporary storage process has low dust content and can be directly fed into the spray tower (plant liquid spray can capture a small amount of suspended particles).

(2) Sludge mixing process (high dust, medium concentration foul odor)

Mixing equipment closed hood → gas collection hood → air duct → pretreatment (cyclone dust collector/inertial dust collector) → plant liquid spray tower (single-stage/two-stage) → fan → standard discharge

Design of Process Parameters for Plant Liquid Spray Tower:

(1) Exhaust gas collection system

Gas collection method:

Temporary storage room: using a "top gas collection hood+side wall ventilation", with a gas collection hood wind speed of ≥ 0.3m/s to ensure that odorous gases do not escape;

Mixing equipment: using a "closed hood+local gas collection hood".

Duct design: The wind speed is controlled at 12-15m/s (to avoid dust deposition), and the duct material is made of FRP or PP. The curvature radius of the elbow is ≥ 1.5 times the pipe diameter to reduce resistance.

Plant liquid spray tower structure and operating parameters:

| parameter type | specific numerical value |

| Handling air volume | 1500~2000m ³/h (calculated based on the volume of the sealing cover multiplied by the air exchange rate of 15~20 times/h) |

| Spray tower specifications | Diameter of 1200mm, height of 6-8m, filling layer height of 2-3m |

| Circulating pump power | 3~5kW, Cycle volume 50~80m ³/h |

| Consumption of plant sap | 0.5~1.0L/h (calculated based on processing air volume) |

| Operating resistance | 800~1200Pa |

Technical parameters of plant liquid spray tower

| parameter name | Definition and Function | Conventional Value Range (Suitable for Chemical/Environmental Scenarios) | Selection calculation logic |

| Processing air volume (Q) | The volume of exhaust gas that can be processed per unit time determines the size of the tower body | 500~10000m ³/h (single tower) | Q=sealed space volume x air exchange rate (15-20 times/h); Such as a 100m ³ sludge temporary storage tank, Q=1500~2000m³/h |

| Empty tower gas velocity (v) | The rising speed of exhaust gas inside the tower affects mass transfer efficiency and resistance | 0.5~1.2m/s (FRP tower body recommended 0.6~0.9m/s) | Excessive gas velocity can easily carry liquid and cause high resistance; If the processing efficiency is too low, it is necessary to balance the air volume and tower diameter (D=√ (4Q/(π v × 3600)) |

| Liquid gas ratio (L/G) | The ratio of circulating liquid flow rate to processing air volume affects the absorption efficiency of pollutants | 1~3L/m ³ (recommended for odorous waste gas is 1.5~2.5L/m ³) | The higher the concentration, the greater the liquid to gas ratio; When the concentration of H ₂ S is greater than 100mg/m ³, L/G≥2L/m³ |

| Contact time (t) | The contact time between exhaust gas and plant liquid determines the efficiency of pollutant treatment | 2-5 seconds (core recommendation 3-4 seconds) | T=height of packing layer (H)/empty tower gas velocity (v); For example, H=2.5m, v=0.8m/s, t=3.125 seconds |

| Operating resistance (Δ P) | The pressure loss of exhaust gas passing through the tower affects the selection of induced draft fan | 800~1500Pa (packing section+defogging section) | Excessive resistance requires an increase in tower diameter or a decrease in air velocity, and the induced draft fan pressure should be ≥ Δ P+pipeline resistance |

table

Last Article: Introduction to Wet Cyclone Dust Collector

Next Article: GRP integrated prefabricated pump station structure